Angular position sensor based on photoelectric detector and measuring method of sensor

A photoelectric detector and angular position technology, which is applied in the direction of transmitting sensing components, measuring devices, measuring heat, etc. by using optical devices, can solve the problems of manual calibration and inconvenient use, and achieve the effect of reducing distortion and ensuring real-time performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

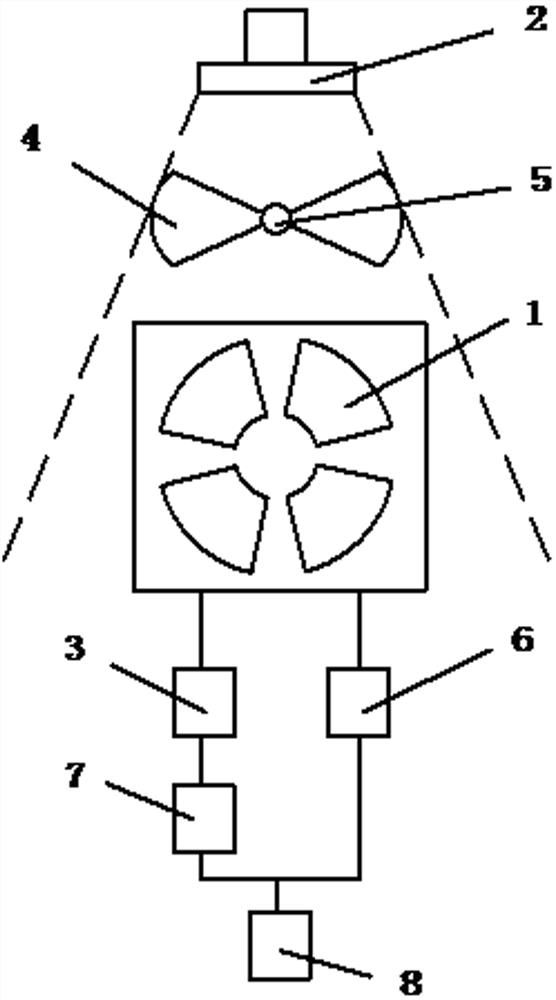

[0035] refer to Figure 1-2 , a specific embodiment of the present invention includes,

[0036] Four fan-shaped photodetectors 1 that are symmetrical around the same axis are used to receive light to generate induced currents. Two non-adjacent fan-shaped photodetectors 1 are connected in series to form a group, and the two groups of fan-shaped photodetectors output two induction currents respectively. current value;

[0037] LD laser diode 2, located on the axis of the four fan-shaped photodetectors 1, is used to emit laser light to the light-receiving surface of the fan-shaped photodetector 1;

[0038] The temperature sensor 3 is used to measure the temperature of the sector photodetector 1;

[0039] Two light-shielding sheets 4 coaxially arranged with the four fan-shaped photodetectors 1, the two light-shielding sheets 4 are fixed on the rotation axis 5 to be measured, the two light-shielding sheets 4 are arranged symmetrically, and the light-shielding sheets 4 are located...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com