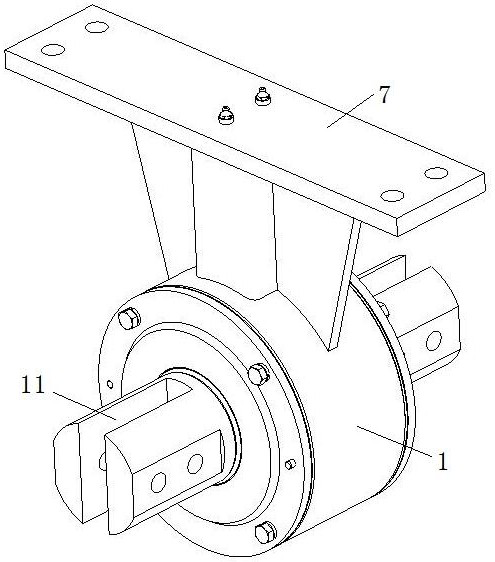

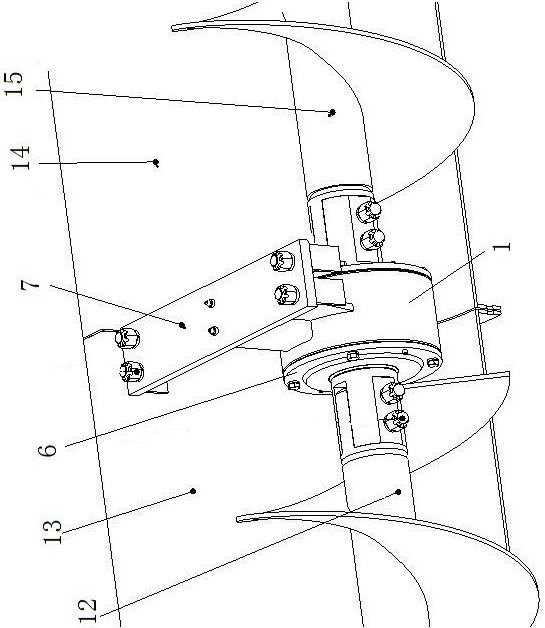

Spiral conveyor hanging bearing

A screw conveyor and bearing technology, applied in the field of material conveying equipment, can solve the problems of poor axial load bearing capacity, low operating rate, complex spline structure, etc., and achieve good radial and axial load bearing, good lubrication and Effect of sealing performance, saving maintenance cost and time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

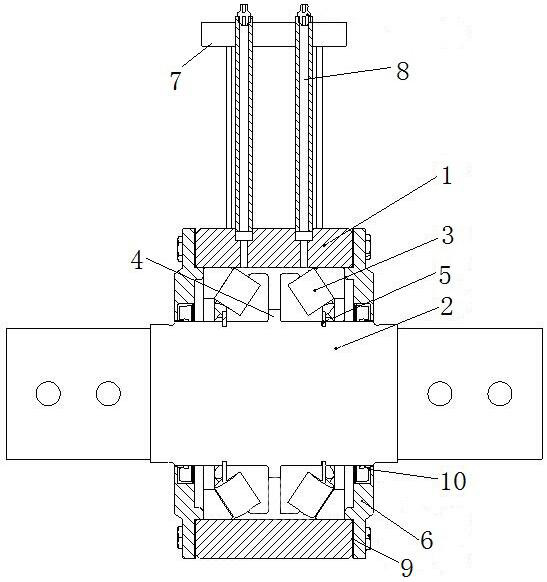

[0026] Such as figure 2 as shown, figure 2 It is a cross-sectional view of the present invention, a screw conveyor suspension bearing, including a bearing seat 1, a main shaft 2 and a bearing 3, the main shaft 2 is provided with a shaft shoulder 4, and the shaft shoulder 4 is located at the center of the bearing seat 1 , the bearings 3 are two and symmetrically distributed on both sides of the shaft shoulder 4, the bearings 3 are tapered roller bearings, and the shaft shoulder 4 is used to separate the two bearings 3 and bear the bearing 3 in the axial direction, the main shaft 2 is also provided with a circlip 5 for limiting the inner ring of the bearing 3, and the circlip 5 is used for axially limiting the inner ring of the bearing 3 The two sides of the bearing block 1 are provided with bearing end covers 6 .

[0027] exist figure 2 Among them, the middle position of the main shaft 2 is integrally provided with a shaft shoulder 4 , and the height of the shaft shoulder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com