Height limiting equipment for bridge construction

A technology of bridge construction and height limit, applied in the direction of restricting traffic, roads, roads, etc., can solve the problems of damage to the height limit device, impact and impact of the height limit device, and achieve the effect of increasing stability and increasing friction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

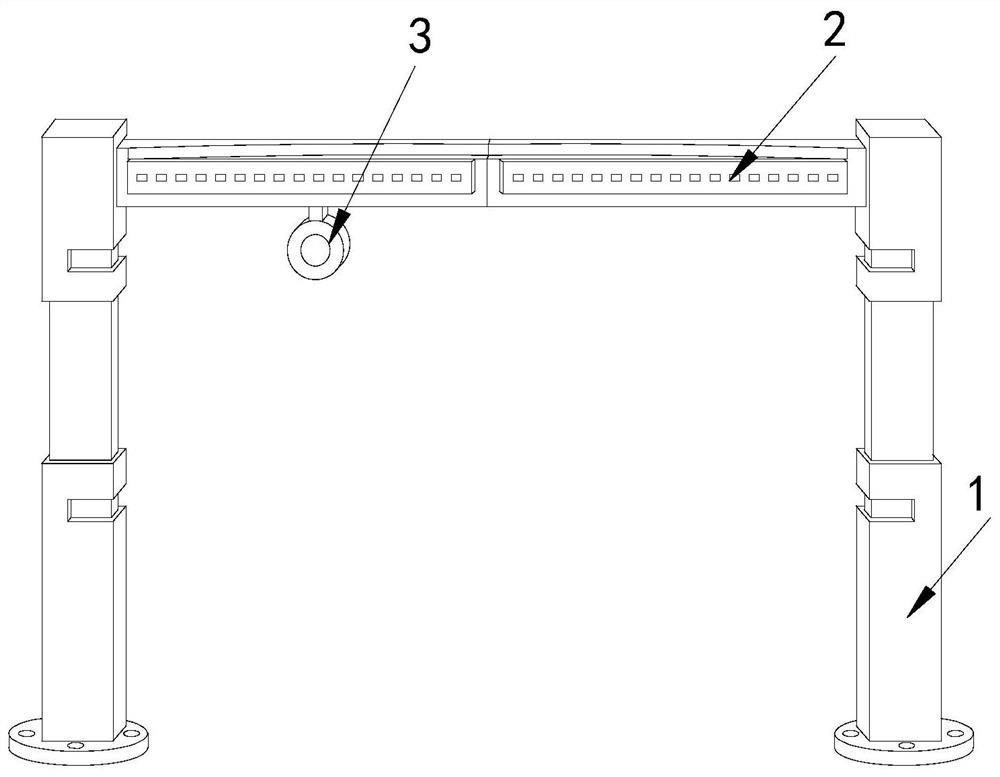

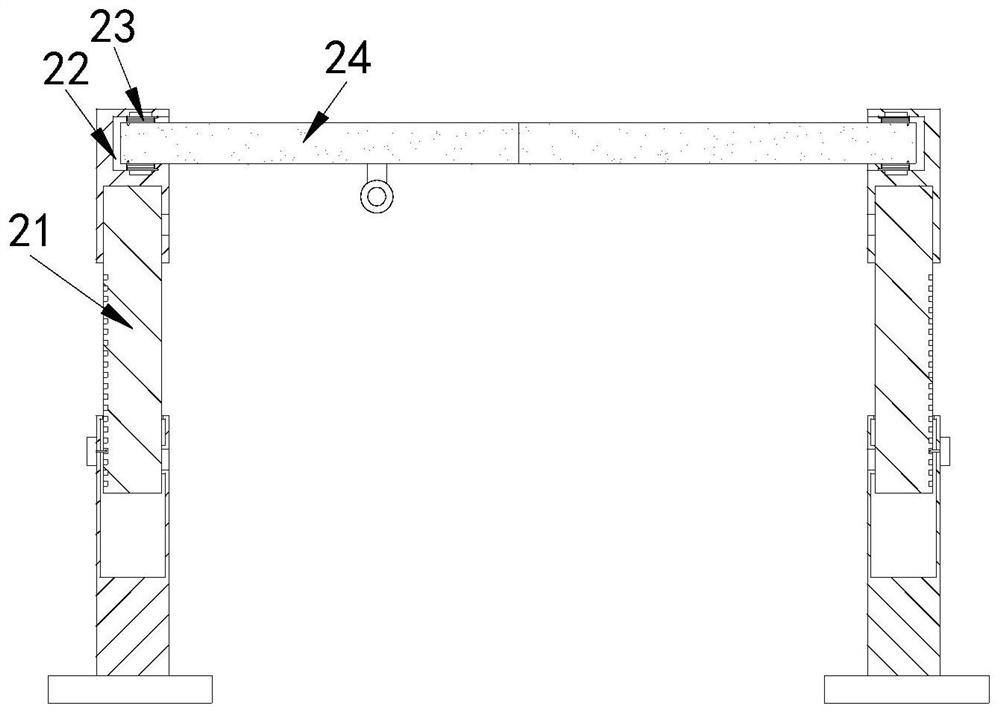

[0026] Example 1: Please refer to Figure 1-Figure 5 , the specific embodiments of the present invention are as follows:

[0027] Its structure includes a supporting column 1, an intercepting device 2, and a warning light 3. The upper end of the supporting column 1 is engaged with an intercepting plate 2, and the warning light 3 is installed at the bottom of the intercepting device 2. The intercepting device 2 includes a telescopic Column 21, rotating groove 22, rewinding spring 23, intercepting plate 24, the top of described telescopic column 21 is provided with rotating groove 22, and described rewinding spring 23 is provided with two, and is arranged on the upper and lower sides of rotating groove 22 respectively. At the end, the intercepting plate 24 is engaged in the rotation groove 22 and is movably matched with the return spring 23 .

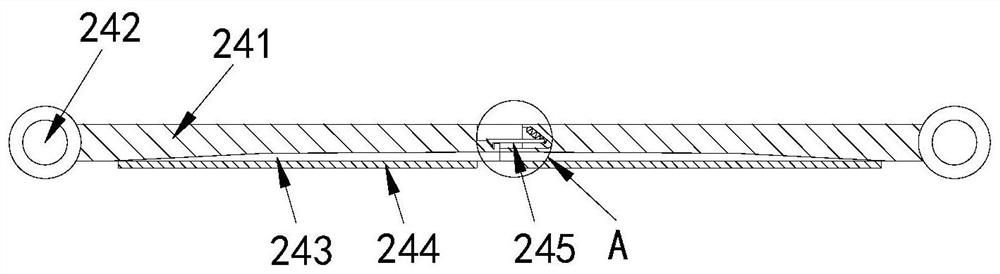

[0028] The intercepting plate 24 includes an intercepting plate body 241, a rotating shaft 242, a guide groove 243, a reflector 244, an...

Embodiment 2

[0032] Example 2: Please refer to Figure 6-Figure 8 , the specific embodiments of the present invention are as follows:

[0033] The engaging rod a3 includes a fixed ring a31, a spring seat a32, a rotating rod a33, and an engaging body a34. Both sides of the fixed ring a31 are provided with a spring seat a32, and the rotating rod a33 is engaged in the fixed ring a31 , the engaging body a34 is embedded in the side end of the fixed ring a31, and the two ends of the rotating rod a33 can rotate, which is beneficial for rolling in the spring groove a1.

[0034] The engaging body a34 includes a barb body b1, a roller b2, and a stabilizing block b3. The bottom of the barb body b1 is provided with four rollers b2, and the rollers b2 are engaged with the barb body b1. The stabilizing block b3 is embedded inside the barb of the barb body b1 , and the bottom end of the roller b2 protrudes from the inside of the barb body b1 , which facilitates the sliding of the barb body b1 on the int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com