Water-based environment-friendly ink and preparation method thereof

A technology of water-based ink and water-based acrylic, which is applied in the direction of ink, household utensils, applications, etc., can solve the problems of insufficient composite strength, slow drying speed, and slow printing speed, and achieve simple and easy preparation methods, fast drying speed, and printing speed fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

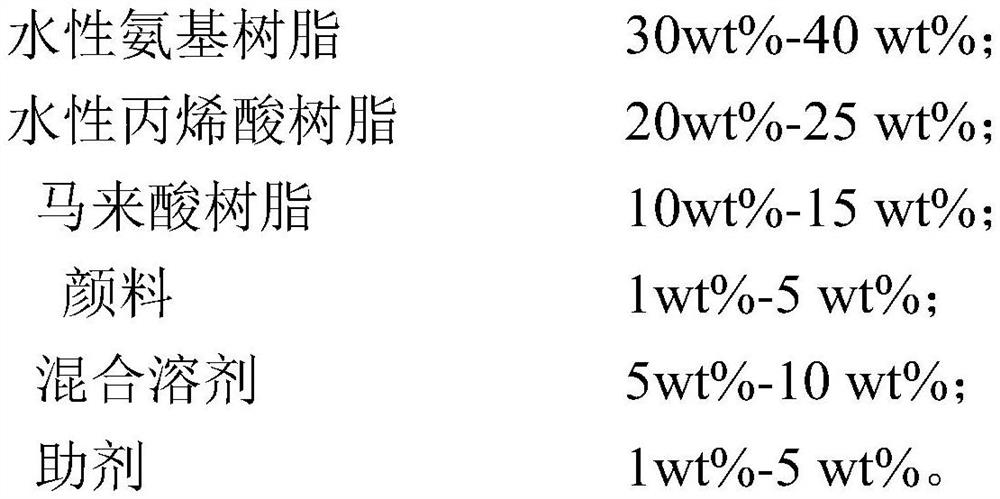

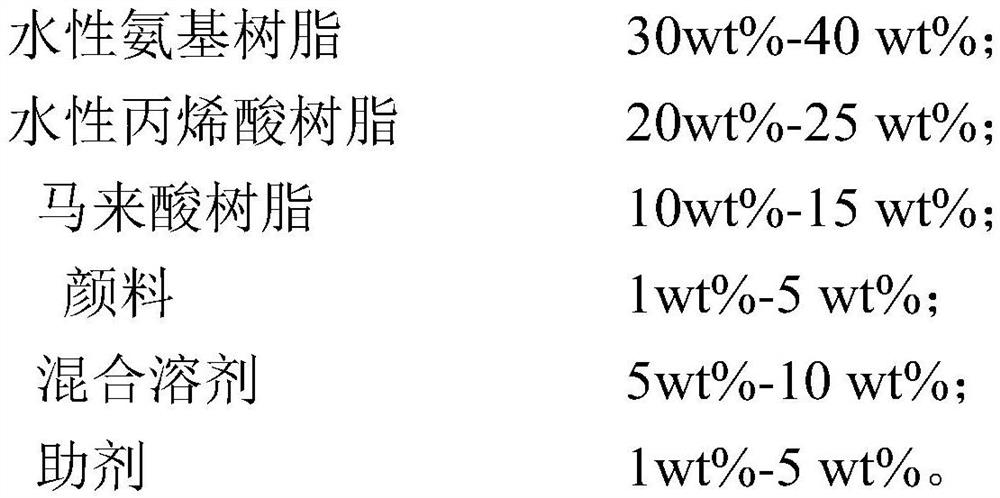

[0035] The method for preparing water-based ink includes the following steps:

[0036] (1) Dissolve the water-based amino resin, water-based acrylic resin, and maleic acid resin in the mixed solvent according to the proportions, and mechanically stir at room temperature until the mixture is uniform to obtain mixed solution A;

[0037] (2) Adding pigments to the prepared mixed liquid A, after mixing uniformly, adding auxiliary agents, and finally adjusting the pH of the mixture to a pH value of 8.0-9.0 with a 0 alkaline solution to prepare the aqueous ink.

[0038] Optionally, the pH value of the mixture is adjusted to 8.0-9.0 by using 0.1 mol / L ammonia water.

[0039] The application of the water-based ink in the packaging box.

[0040] Optionally, the application of the water-based ink in a food packaging box.

[0041] Optionally, the application of the water-based ink in a cosmetic packaging box.

Embodiment 1

[0044] (1) Dissolve the water-based amino resin, water-based acrylic resin, and maleic acid resin in a mixed solvent with a volume ratio of water and ethanol of 10:3 according to a mass percentage of 2:1:1, and mechanically stir at room temperature until the mixture is uniform , Prepare mixed solution A;

[0045] (2) Add carbon black to the prepared mixture A. After mixing uniformly, add defoamer, leveling agent and surfactant, and finally adjust the pH of the mixture to 8.0-9.0 with an alkaline solution to obtain the 述Water-based ink.

Embodiment 2

[0047] (1) Dissolve the water-based amino resin, water-based acrylic resin and maleic acid resin in a mixed solvent with a volume ratio of water and ethanol of 10:4 according to a mass percentage of 2:1.2:1, and mechanically stir at room temperature until they are uniform , Prepare mixed solution A;

[0048] (2) Add titanium dioxide to the prepared mixture A. After mixing uniformly, add defoamer, leveling agent and surfactant, and finally adjust the pH of the mixture to 8.0-9.0 with an alkaline solution to prepare the Water-based ink.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com