Two-way cable laying operation vehicle for highway

A technology of two-way cables and work vehicles, which is applied to cable laying equipment, conveying filamentous materials, thin material processing, etc., can solve the problems of high labor intensity, low efficiency, and large number of workers, so as to reduce labor costs and ensure safety Sexuality, the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

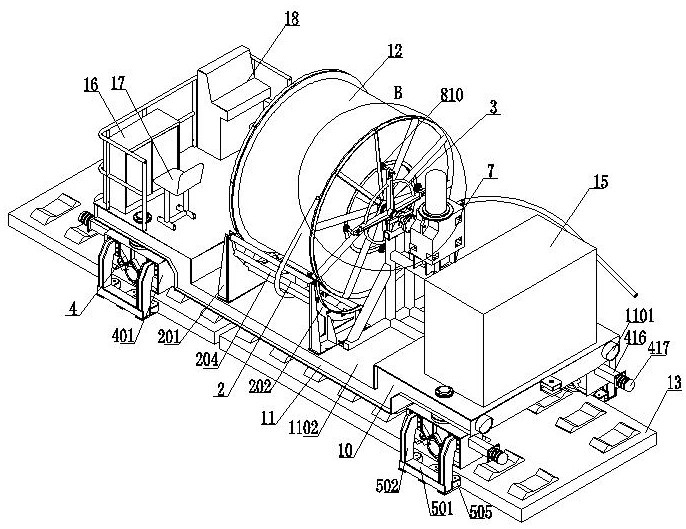

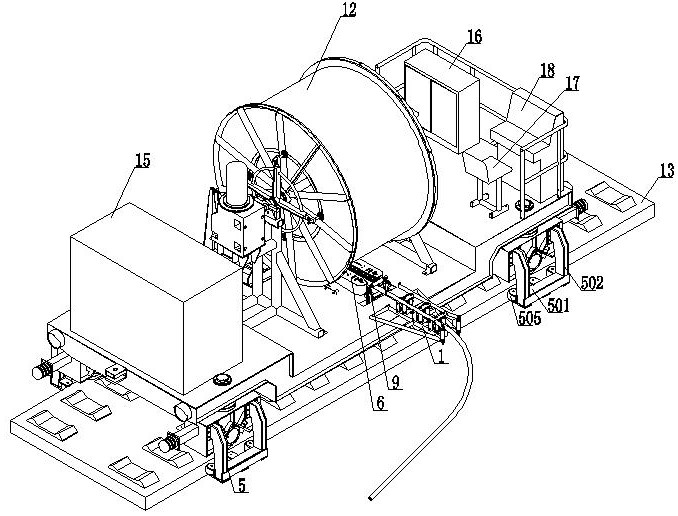

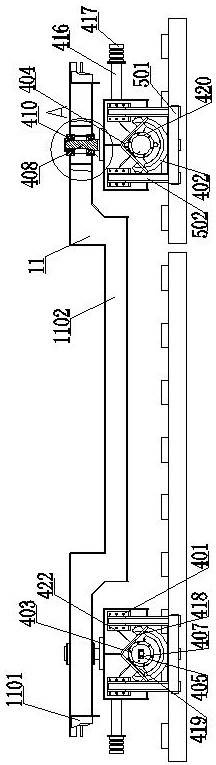

[0026] In order to better illustrate the present invention, it is further described in conjunction with examples.

[0027] A high-speed rail two-way cable laying operation vehicle, such as figure 1 and figure 2 , image 3 As shown, the work vehicle travels on the railway track slab 13, the work vehicle includes a chassis assembly 10, the chassis assembly 10 includes a vehicle frame 11, and the middle part of the vehicle frame 11 is fixedly connected with an unwinding device 3 for unwinding cables, Optionally, in order to reduce the height of the chassis, the middle part of the vehicle frame 11 is provided with a sunken part 1102 sunken downwards, and the bottom of the sunken part 1102 is spaced apart from the railway track plate 13, which reduces the height of the center of gravity of the vehicle frame 11 to improve Stability while walking. The bottom of the vehicle frame 11 is equipped with four groups of walking trolleys 4 for driving the vehicle frame 11 to walk. The wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com