Logistics express sorting machine

A sorter and logistics technology, applied in the field of logistics, can solve the problems of high belt tension, short belt service life, derailment and other problems, and achieve the effect of reducing friction and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

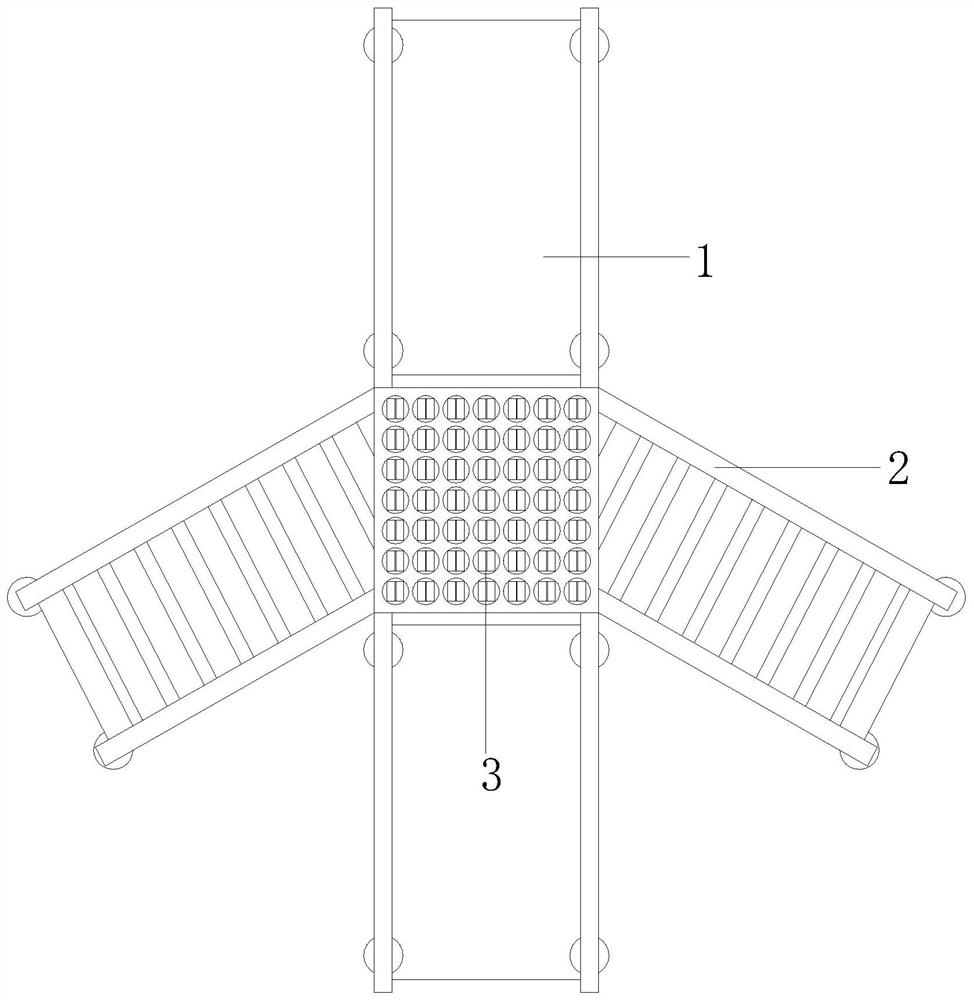

[0027] like figure 1 As shown, the present invention provides a technical scheme of a logistics express sorting machine: its structure includes a belt conveyor 1, a roller conveyor 2, an inclined balance wheel sorting device 3, and the front and rear sides of the inclined balance wheel sorting device 3 Belt conveyors 1 are provided at the ends, and roller conveyors 2 are provided at the left and right sides of the inclined balance wheel sorting device 3 .

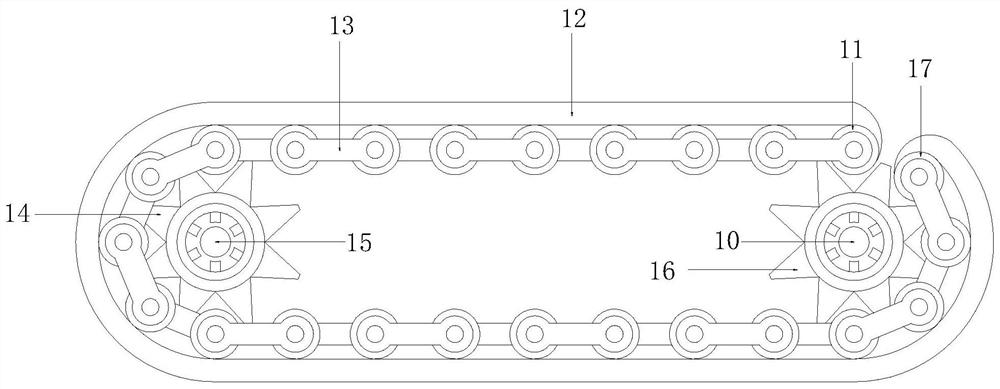

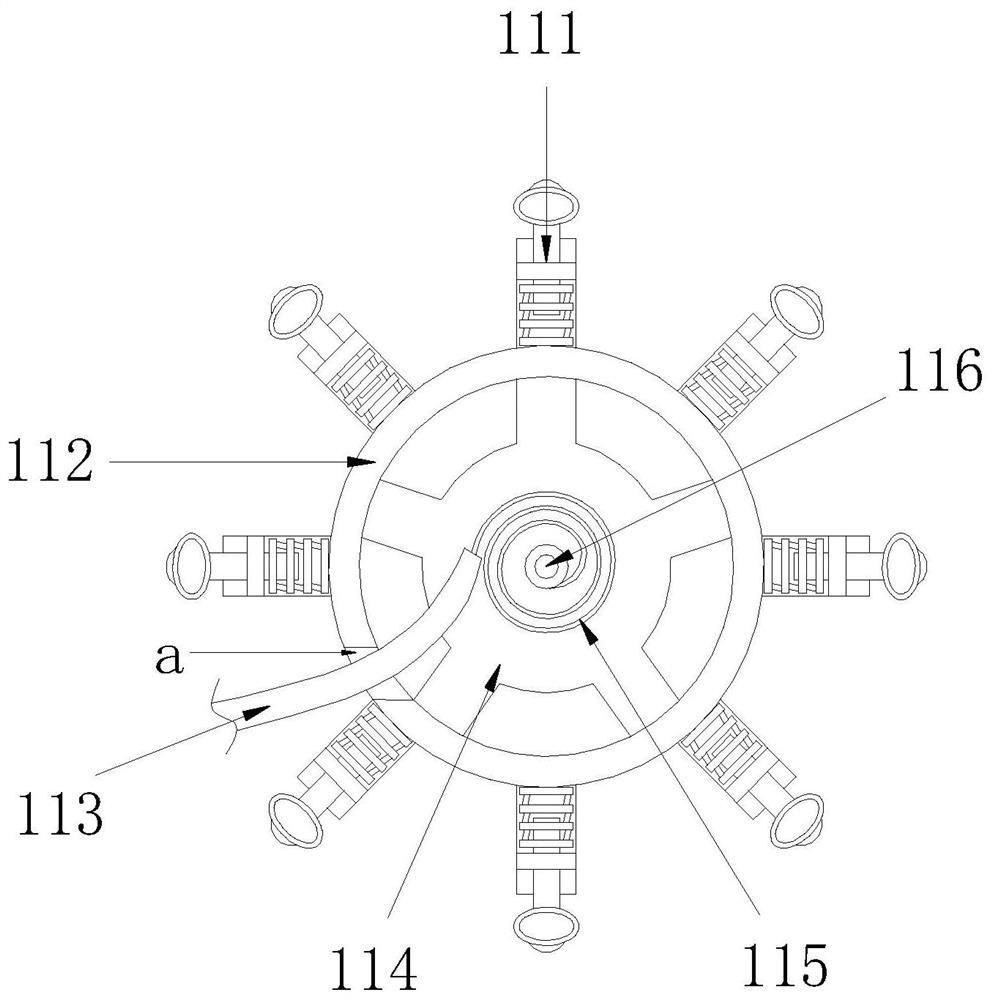

[0028] like figure 2 As shown, the belt conveyor 1 includes a driving shaft 10, a winding assembly 11, a belt 12, a chain 13, a No. 1 gear 14, a driven shaft 15, a No. 2 gear 16, and a connecting cylinder 17. The driving shaft 10 No. 2 gear 16 is installed at both ends of the driven shaft 15, and No. 1 gear 14 is installed at both ends of the driven shaft 15. The No. 1 gear 14 and No. 2 gear 16 are connected by a chain 13, and the chain 13 is set There are two, one end of the two chains 13 is connected through the windi...

Embodiment 2

[0032] like Figure 1-2 As shown, the present invention provides a technical scheme of a logistics express sorting machine: its structure includes a belt conveyor 1, a roller conveyor 2, an inclined balance wheel sorting device 3, and the front and rear sides of the inclined balance wheel sorting device 3 Both ends are equipped with belt conveyors 1, and the left and right sides of the inclined balance wheel sorting device 3 are equipped with roller conveyors 2. The belt conveyor 1 includes a driving shaft 10, a winding assembly 11, a belt 12, Chain 13, No. 1 gear 14, driven shaft 15, No. 2 gear 16, connecting cylinder 17, No. 2 gear 16 is installed on the two ends of described driving shaft 10, and a No. gear 14, the No. 1 gear 14 and the No. 2 gear 16 are connected through a chain 13. The chain 13 is provided with two. One end of the two chains 13 is connected by a winding assembly 11, and the other end is connected by a winding assembly 11. The connecting cylinder 17 is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com