Ultra-high performance concrete conveying and batching device

An ultra-high performance, concrete technology, applied in clay preparation devices, raw material supply devices for sale, cement mixing devices, etc., can solve problems such as inability to mix concrete, and achieve the effect of ingenious structure, good effect, and easy use and operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

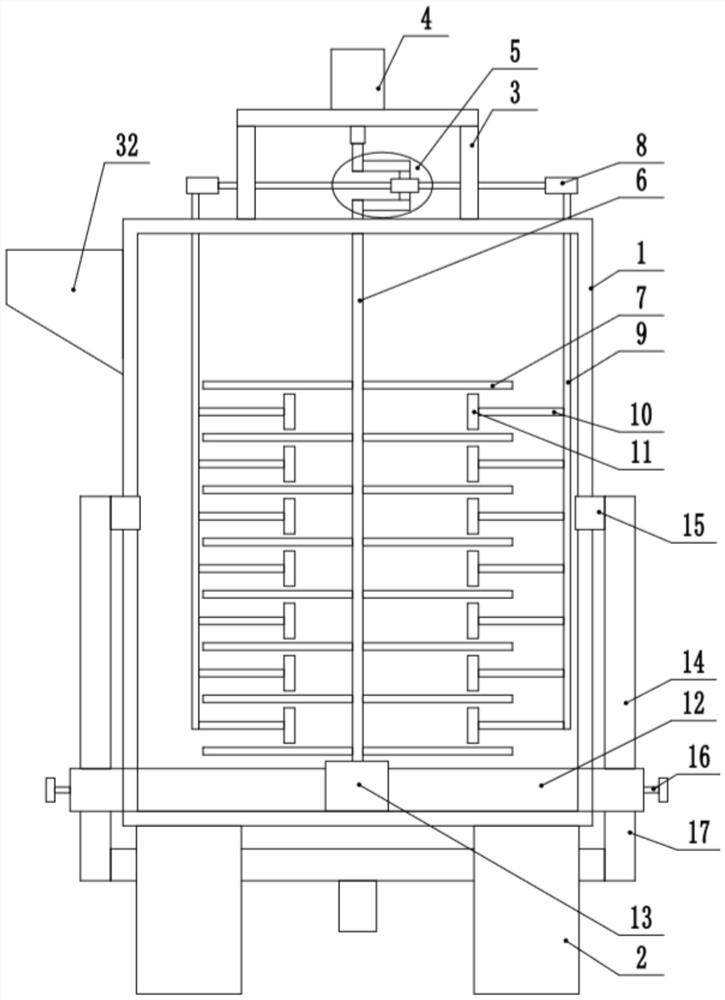

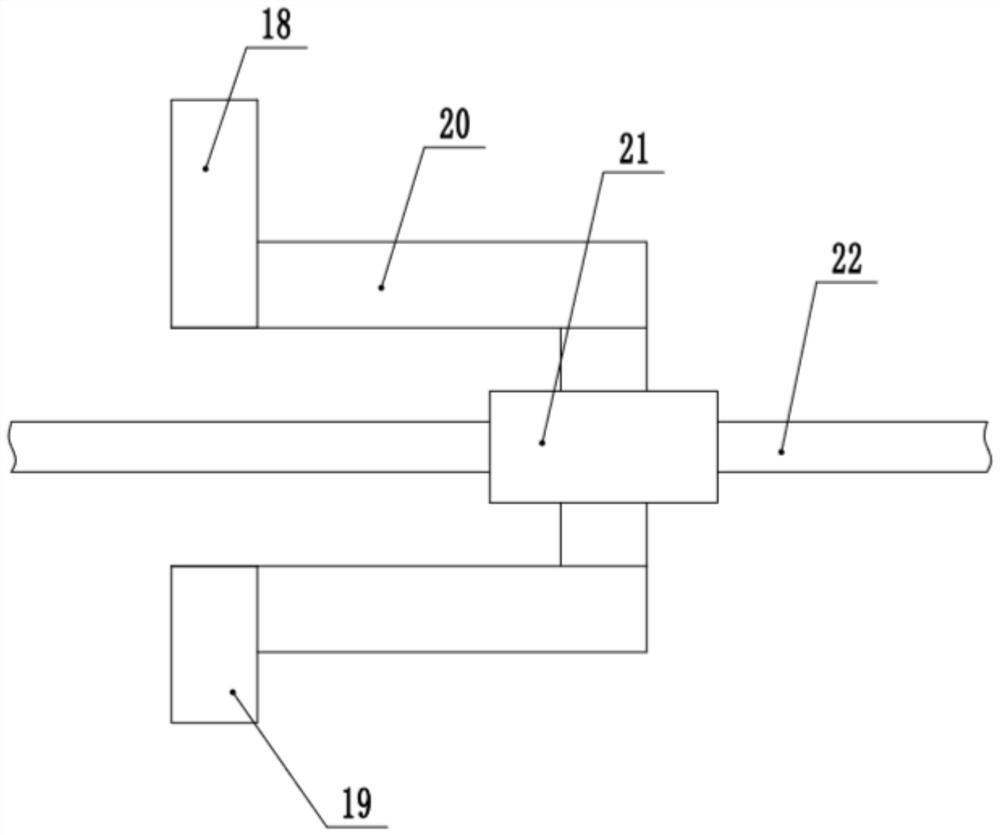

[0022] see Figure 1-4 , a kind of ultra-high-performance concrete conveying batching device, comprises mixing box 1, and the bottom four corners of mixing box 1 are all fixedly connected support leg 2, and the upper side of one side of mixing box 1 is fixedly connected with feeding hopper 32, and described mixing box 1 The top of the box 1 is fixedly connected to the top frame 3, the top of the top frame 3 is fixedly connected to the drive motor 4, the output shaft of the drive motor 4 is fixedly connected to the linkage device 5, and the mixing box 1 is provided with a stirring mechanism and a reciprocating material pushing mechanism. The bottom end of the middle cover 13 is fixedly connected to the middle cover 13, and both sides of the middle cover 13 are fixedly connected to the bottom pipe 12. The end of the bottom pipe 12 away from the middle cover 13 passes through the mixing tank 1, and the top of the end of the bottom pipe 12 away from the middle cover 13 is fixed. C...

Embodiment 2

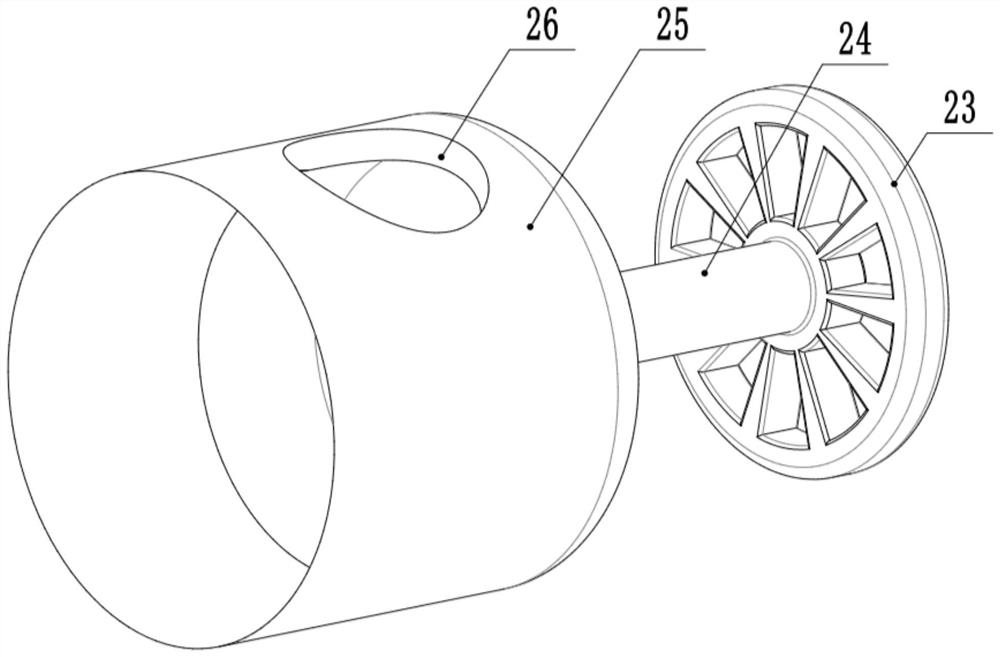

[0029] see Figure 1-4 , the other content of this embodiment is the same as that of Embodiment 1, the difference is that: the feeding switching device 16 includes a second rotating sleeve 25 that is rotatably connected to the inner side of the end of the bottom pipe 12, and the second rotating sleeve 25 is provided with The material delivery port 26 and the end of the second rotating sleeve 25 are fixedly connected to the switching rod 24 , and the switching rod 24 passes through the bottom pipe 12 and is fixedly connected to the hand wheel 23 .

[0030] In the implementation process of the present invention, each raw material of concrete is poured into the mixing box 1 from the feed hopper 32, and then the driving motor 4 is started, and the driving motor 4 drives the U-shaped curved rod 20 to rotate, thereby rotating the rotating shaft 6, and the rotating shaft 6 Drive the stirring paddle 7 to rotate to realize the stirring of the concrete, and at the same time, the U-shape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com