Plate drilling device for numerical control equipment

A technology of drilling device and numerical control equipment, which is applied in the field of plate processing, can solve the problems of complex operation and generation of debris, and achieve the effect of avoiding debris splashing and improving drilling quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

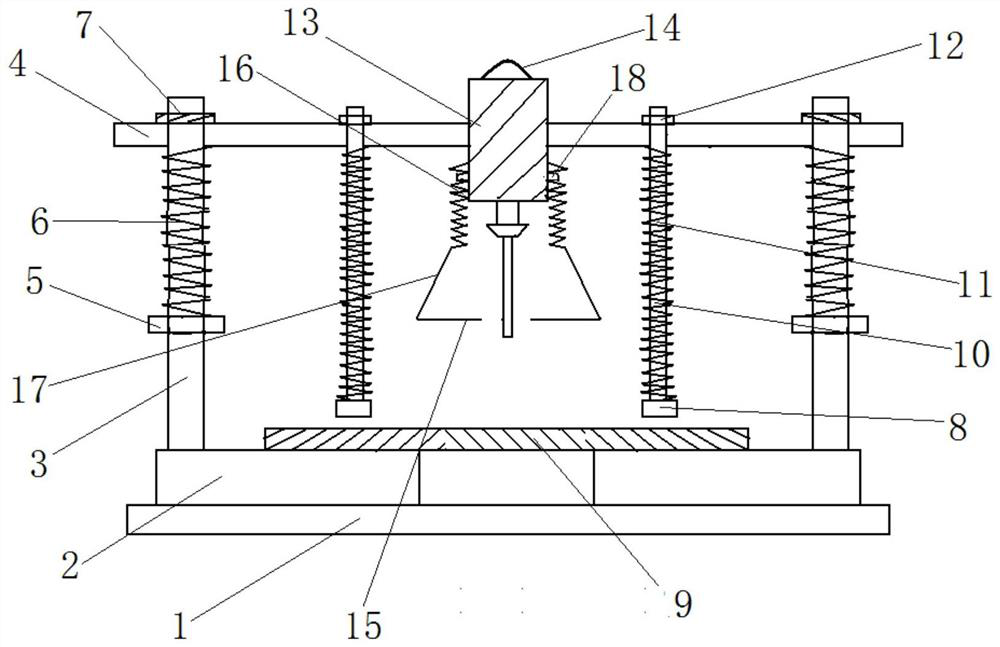

[0015] Such as figure 1 As shown, the present invention discloses a plate drilling device for numerical control equipment, including a bottom plate 1, on which two support plates 2 are arranged in parallel, and the support plates 2 are used to support the plate 9, and between the two support plates 2 There is spacing, which is convenient for drilling machine 13 to drill holes.

[0016] Support plate 2 is connected with some vertical rods 3, and the upper end of vertical rod 3 passes the upper end of drilling machine mounting plate 4, and the middle part of drilling machine mounting plate 4 is fixed with drilling machine 13, and drilling machine 13 rear ends are connected with handle14. The num...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com