Method for preparing metal gradient material through selective laser melting

A technology of selective laser melting and gradient materials, applied in the field of additive manufacturing, can solve the problems of complex process equipment and high cost, and achieve the effect of improving performance, low cost and reducing raw material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] The René 104 nickel-based superalloy powder with a particle size of 15-53 μm is used as the raw material. The composition of the René 104 nickel-based superalloy is: 20.6Co~13Cr~3.4Al~3.9Ti~3.8Mo~2.1W~2.4Ta~0.9Nb~ 0.05Zr~0.03B~0.04C~the balance is Ni. Include the following steps:

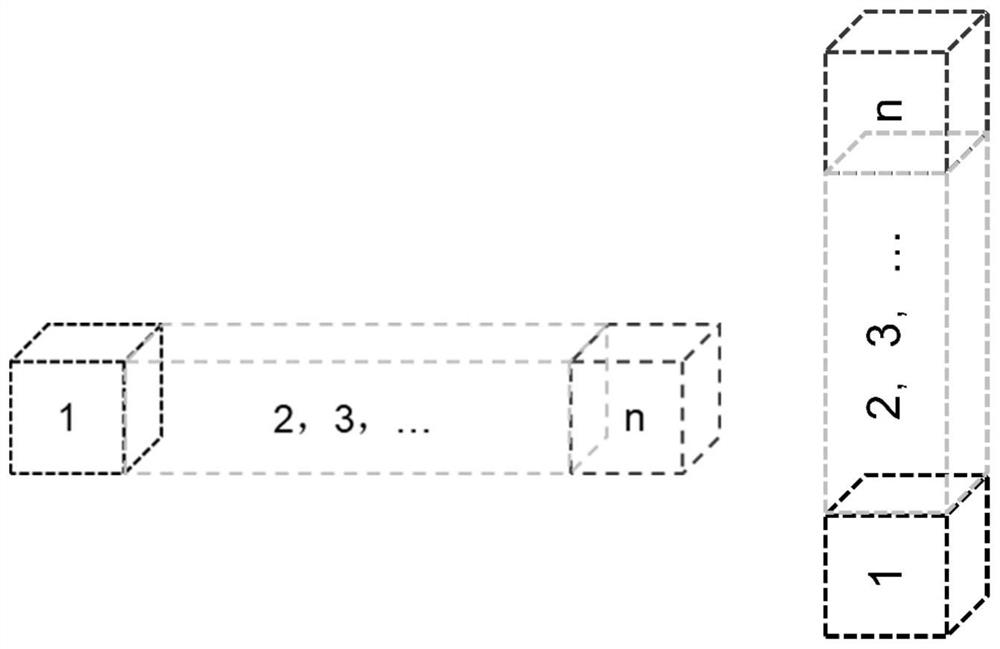

[0054] (1) According to the service environment, design the microstructure of different partitions of the metal gradient material, thereby dividing the workpiece model into 3 partitions, from 1 partition to 3 partitions, the grain size gradually becomes smaller;

[0055] (2) Establish three-dimensional computer models of three different partitions, and then assemble them into a three-dimensional model of the overall part. The partitions are overlapped with each other, and the width of the overlapping zone is designed to be the width of a molten pool;

[0056] (3) According to the microstructure characteristics of the three different partitions, set the 3D printing parameters and scanning pat...

Embodiment 2

[0064] The René 104 nickel-based superalloy powder with a particle size of 15-53 μm is used as the raw material. The composition of the René 104 nickel-based superalloy is: 20.6Co~13Cr~3.4Al~3.9Ti~3.8Mo~2.1W~2.4Ta~0.9Nb~ 0.05Zr~0.03B~0.04C~the balance is Ni. Include the following steps:

[0065] (1) When designing the microstructure of the metal gradient material into 3*2 different partitions, control the laser power of the first partition to the third partition to be 400, 300, 200W respectively, and the laser scanning speed to be 800mm / s, 900mm / s, 1000mm / s;

[0066] (2) Establish three-dimensional computer models of three different partitions, and then assemble them into a three-dimensional model of the overall part. The different partitions are overlapped with each other, and the width of the overlapping area is the width of a molten pool; the first partition is and the substrate The contact area; the second division is located between the first division and the third divi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com