A method for selective desorption and recycling of mineral surface agents

A selective and medicament-based technology, applied in flotation, solid separation, etc., can solve the problems of high waste water treatment cost, low efficiency, and high cost of chelating chemicals in smelting enterprises, so as to achieve sustainable recycling and protect the ecological environment , Guarantee the effect of economic benefit and sustainable development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

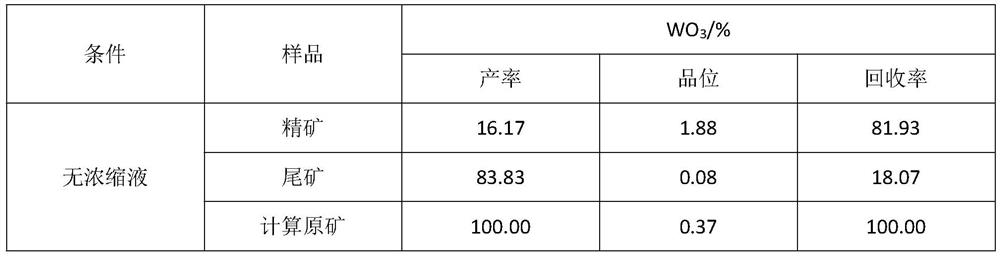

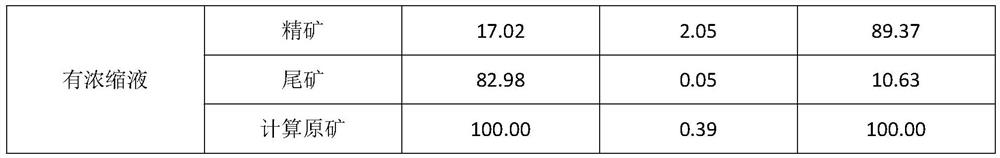

[0040] The sulfur tailings (tungsten raw ore) from a dressing plant in Chenzhou, Hunan Province were subjected to tungsten flotation, of which WO 3 The grade is 0.40%, the gangue is mainly garnet and calcite, the amount of roughing collector is 600g / t of lead nitrate, 500g / t of benzyl hydroxamic acid, the pH of the pulp flotation is 9.0, the flotation is 6min, and the flotation machine The stirring speed is 2000r / min, and the flotation results (without concentrate) are shown in Table 1. Then, put the above-mentioned tungsten concentrate slurry into the agitator, adjust the slurry concentration to 25%, and the stirring speed to 2700r / min, then add desorbent sodium hydroxide 60g / t (for tungsten raw ore), and after stirring for 15min, the slurry immediately Enter the centrifuge to concentrate, and the centrifugal concentrate containing a large amount of beneficial collectors is returned to the original flotation process for use. Concentrate color see figure 1shown. After addin...

Embodiment 2

[0045] The tin ore (tin raw ore) taken from an old dressing plant in Yunnan is subjected to flotation, wherein the Sn grade is 0.55%, the gangue is mainly quartz and feldspar, and the amount of roughing collector is 500g / t of lead nitrate, benzene Hydroxamic acid is 700g / t, the amount of inhibitor water glass is 300g / t, the slurry flotation pH is 8.0, No. 2 oil is 40g / t, and the speed is 2000r / min. The flotation results (without concentrate) are shown in Table 2. Then, put the above-mentioned tin concentrate pulp into the agitator, adjust the pulp concentration to 30%, and the stirring speed to 2800r / min, then add desorbent hydrochloric acid 80g / t (for tin ore), after stirring for 20min, the pulp enters the centrifuge immediately Concentrated by machine, the centrifuge concentrate containing a large amount of beneficial collectors is returned to the original flotation process for use. After adding the concentrate, the dosages of lead nitrate and benzohydroxamic acid were reduc...

Embodiment 3

[0049] The rare earth ore (bastnaesite raw ore) taken from a dressing plant in Mianning, Sichuan, was subjected to flotation. The REO grade was 3.06%, and the gangue was mainly feldspar, quartz, barite and fluorite. The dosage is 3000g / t, the collector salicylic hydroxamic acid dosage is 4000g / t, the No. 2 oil is 40g / t, the speed is 2000r / min, and the flotation results (without concentrate) are shown in Table 3. Then, put the above-mentioned rare earth concentrate ore slurry into the agitator, adjust the slurry concentration to be 35%, and the stirring speed is 2600r / min, then add desorbent sodium hydroxide 80g / t (for bastnaesite raw ore), after stirring for 25min, The ore pulp then enters the centrifuge to concentrate, and the centrifugal concentrate containing a large amount of beneficial collector is returned to the original flotation process for use. After adding the concentrate, the dosage of salicylic hydroxamic acid was reduced to 3000g / t, and the other flotation condit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com