Antibacterial and high-temperature-resistant hydrocolloid and preparation method thereof

A hydrocolloid, high-temperature-resistant technology, applied in medical science, bandages, absorbent pads, etc., can solve problems such as hydrocolloid adhesion, overflow glue, and lack of antibacterial and anti-inflammatory properties, and achieve simple operation, prevention of wound inflammation, and easy-to-control technology Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

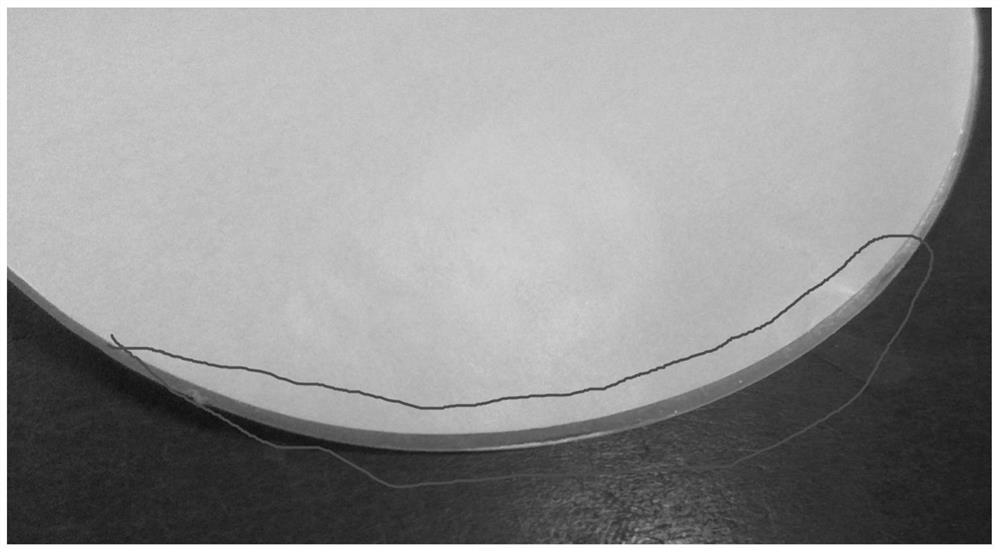

Image

Examples

Embodiment 1

[0034] The present embodiment provides a kind of antibacterial, the preparation method of high temperature resistant hydrocolloid, comprises the following steps:

[0035] (1) Mix 150g of SBS, 100g of naphthenic oil and 10g of dibutyl hydroxytoluene, heat and melt at 120°C, and homogenize at a stirring speed of 20r / min for 0.5h to obtain mixture a;

[0036] (2) Maintain the temperature at 120°C, add 180g HIKOREZT-1080 to the mixture a obtained in step (1), and homogenize at a stirring speed of 20r / min for 0.5h to obtain mixture b;

[0037] (3) Maintain a temperature of 120°C, add 180 g of sodium carboxymethylcellulose to the mixture b obtained in step (2), and homogenize at a stirring speed of 20 r / min for 0.3 h at the same time to obtain a mixture c;

[0038] (4) Maintain the temperature of 120°C, add 10g of Manuka honey to the mixture c obtained in step (3), and homogenize at a stirring speed of 20r / min for 0.5h to obtain the mixture d; extrude the mixture d and heat it at 90...

Embodiment 2

[0040] The present embodiment provides a kind of antibacterial, the preparation method of high temperature resistant hydrocolloid, comprises the following steps:

[0041] (1) Mix 480g SIS, 250g naphthenic oil and 80g dibutyl hydroxytoluene, heat up to 190°C for melting, and homogenize at a stirring speed of 80r / min for 3 hours to obtain mixture a;

[0042] (2) Maintain the temperature at 190°C, add 390g HIKOREZT-1080 to the mixture a obtained in step (1), and homogenize at a stirring speed of 60r / min for 3 hours to obtain mixture b;

[0043] (3) Maintain a temperature of 190°C, add 390 g of sodium carboxymethylcellulose to the mixture b obtained in step (2), and homogenize at a stirring speed of 60 r / min for 2 hours to obtain a mixture c;

[0044] (4) Maintain the temperature at 190°C, add 150g of Manuka honey to the mixture c obtained in step (3), and homogenize at a stirring speed of 60r / min for 1 hour to obtain the mixture d; extrude the mixture d and carry out at 150°C Co...

Embodiment 3

[0046] The present embodiment provides a kind of antibacterial, the preparation method of high temperature resistant hydrocolloid, comprises the following steps:

[0047] (1) Mix 310g SEBS, 170g naphthenic oil and 40g dibutyl hydroxytoluene, heat up to 150°C for melting, and homogenize at a stirring speed of 50r / min for 1.5h to obtain mixture a;

[0048] (2) Maintain the temperature at 150°C, add 280g HIKOREZT-1080 to the mixture a obtained in step (1), and homogenize at a stirring speed of 40r / min for 1.5h to obtain mixture b;

[0049] (3) Maintain a temperature of 150°C, add 280 g of sodium carboxymethylcellulose to the mixture b obtained in step (2), and homogenize at a stirring speed of 40 r / min for 1 hour to obtain a mixture c;

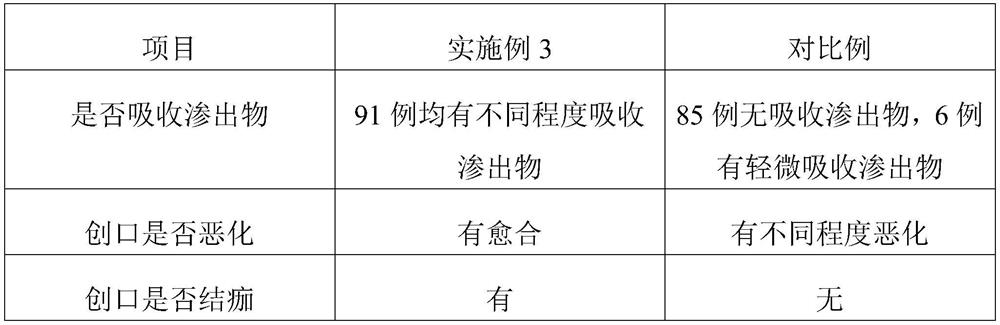

[0050] (4) Maintain the temperature of 150°C, add 80g of Manuka honey to the mixture c obtained in step (3), and homogenize at a stirring speed of 40r / min for 0.7h to obtain the mixture d; extrude the mixture d and heat it at 150°C Coating, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com