Silage as well as preparation method and application thereof

A technology of silage and feed, applied in the field of silage preparation, which can solve the problems of decreased feed intake, poor absorption, and poor taste of farmed animals, and achieve the goals of increasing animal feed intake, reducing fat deposition, and reducing content Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

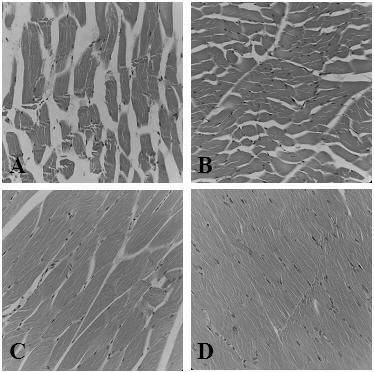

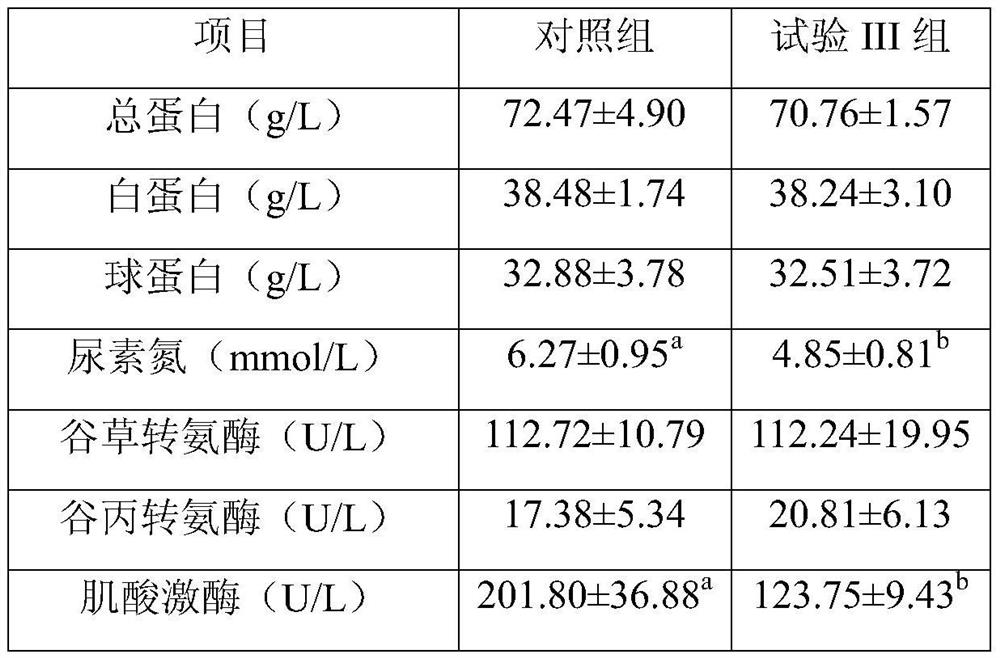

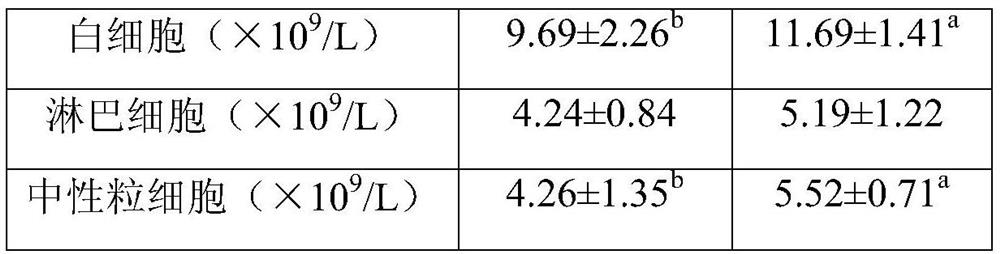

Image

Examples

Embodiment 1

[0036] A preparation method of eucommia silage, comprising the steps of:

[0037] The first step, the preparation of additive I eucommia leaf powder:

[0038] (1) Raw materials of fresh leaves: fresh leaves of Eucommia ulmoides that grow lushly from June to October;

[0039] (2) Finishing: Use a drum fixing machine to finish for 4 minutes at 230°C;

[0040] (3) Drying: Dry at 55°C for 20 hours.

[0041] (4) Pulverization: pulverize into coarse powder, and the coarse powder is passed through a 24-mesh sieve.

[0042] The second step, the preparation of additive II probiotics

[0043] Mix Lactobacillus plantarum, Lactobacillus acidophilus, Bacillus subtilis, and Enterococcus faecalis in a mass ratio of 5:2:4:2.5 to obtain a composite bacterial powder; in the composite bacterial powder, Lactobacillus plantarum, Lactobacillus acidophilus, Bacillus subtilis, The effective number of viable bacteria of Enterococcus faecalis was 4×10 10 cfu / g, 2×10 10 cfu / g, 9.5×10 10cfu / g, 3×1...

Embodiment 2

[0053] The silage for sheep is made from the following raw material proportions by weight: 10% of eucommia leaf powder and 89% of corn stalks.

[0054] A preparation method of eucommia silage, comprising the steps of:

[0055] The first step, the preparation of additive I eucommia leaf powder:

[0056] (1) Raw materials of fresh leaves: fresh leaves of Eucommia ulmoides that grow lushly from June to October;

[0057] (2) Finishing: Use a drum fixing machine to finish for 4 minutes at 230°C;

[0058] (3) Drying: specifically drying at 60° C. for 15 hours.

[0059] (4) Pulverization: pulverize into coarse powder, and the coarse powder passes through a 50-mesh sieve.

[0060] The second step, the preparation of additive II probiotics

[0061] Mix Lactobacillus plantarum, Lactobacillus acidophilus, Bacillus subtilis, and Enterococcus faecalis in a mass ratio of 6:3:5:3 to obtain a composite bacterial powder; in the composite bacterial powder, Lactobacillus plantarum, Lactobaci...

Embodiment 3

[0071] A kind of production method of eucommia silage, the steps are as follows:

[0072] The first step, the preparation of additive I eucommia leaf powder:

[0073] (1) Raw materials of fresh leaves: fresh leaves of Eucommia ulmoides that grow lushly from June to October;

[0074] (2) Finishing: Use a drum fixing machine to finish for 4 minutes at 230°C;

[0075] (3) Drying: specifically drying at 65° C. for 10 hours.

[0076] (4) Pulverization: pulverize into coarse powder, and the coarse powder passes through a 10-mesh sieve.

[0077] The second step, the preparation of additive II probiotics

[0078] Mix Lactobacillus plantarum, Lactobacillus acidophilus, Bacillus subtilis, and Enterococcus faecalis in a mass ratio of 7:4:6:3 to obtain a composite bacterial powder; in the composite bacterial powder, Lactobacillus plantarum liquid, Lactobacillus acidophilus liquid, and Bacillus subtilis The effective number of viable bacteria in bacillus liquid and Enterococcus faecali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com