Device and method for vibration antifogging through capillary driving of variable cross-section beam

A variable-section beam and capillary technology, applied in heat exchange equipment, lighting and heating equipment, heat transfer modification and other directions, can solve the problems of low operating efficiency and increased energy consumption, and achieve low cost, compact structure and convenient manufacturing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

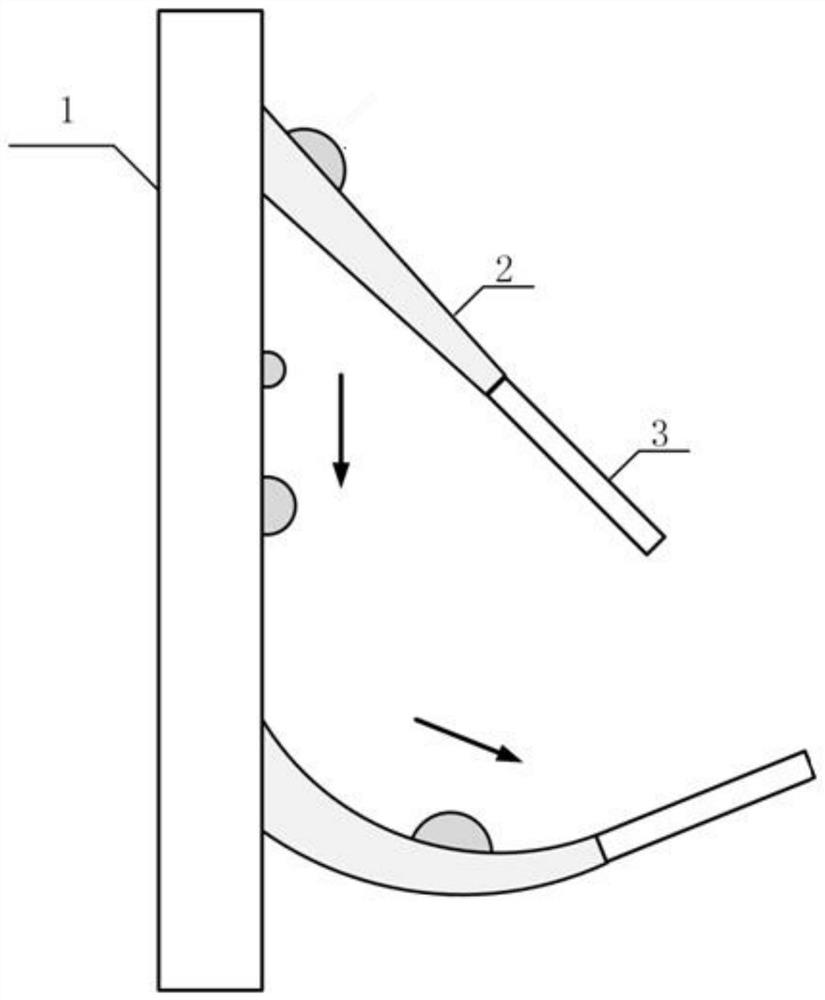

[0023] As shown in the figure: a device for vibration and anti-fog using capillary drive of variable cross-section beams, including:

[0024] Hydrophobic Substrate 1;

[0025] The variable-section beam 2, the cross-section of the variable-section beam 2 is gradually reduced from the left end to the right end, and the variable-section beam 2 is installed on the right side of the hydrophobic base 1 in an oblique shape;

[0026] The hydrophilic rod 3 is connected with the right end of the variable section beam 2 .

[0027] The variable-section beam 2 is made of rubber material; the variable-section beam 2 made of rubber material has certain elasticity, can realize bending and rebound, and its surface is a weakly hydrophilic surface.

[0028] The surface of the hydrophilic rod 3 is coated with a hydrophilic coating.

[0029] The hydrophilicity o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com