Hot melt type gas-liquid two-phase heat exchanger

A hot melt and heat exchanger technology, applied in the direction of heat exchanger types, heat exchanger shells, indirect heat exchangers, etc., can solve the problems of difficulty in improving the utilization rate of heat exchange materials and inability to further improve heat exchange capacity, etc. Achieving the effect of wide range of use, reduced printing difficulty and excellent sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

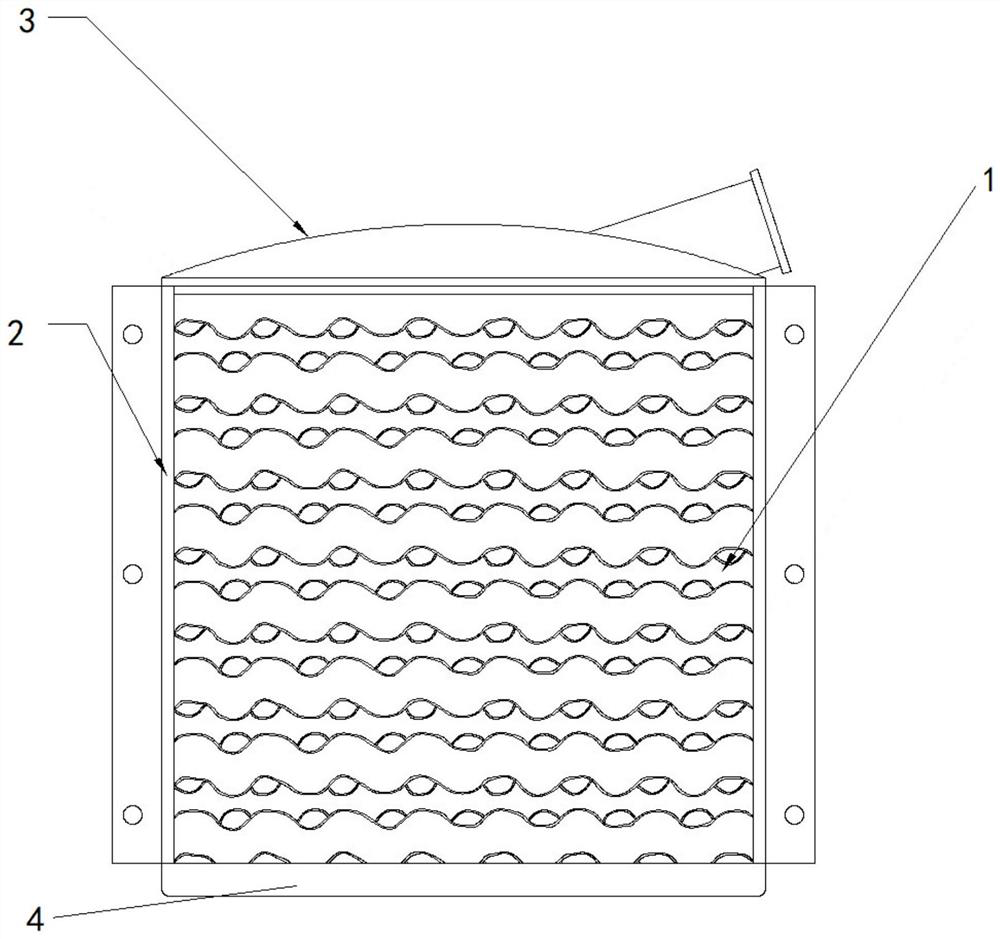

[0040] The hot melt type gas-liquid two-phase heat exchanger in the present invention includes a core body 1, a sealing wall 2, a drainage assembly 3 and a baffle assembly 4, see figure 1 .

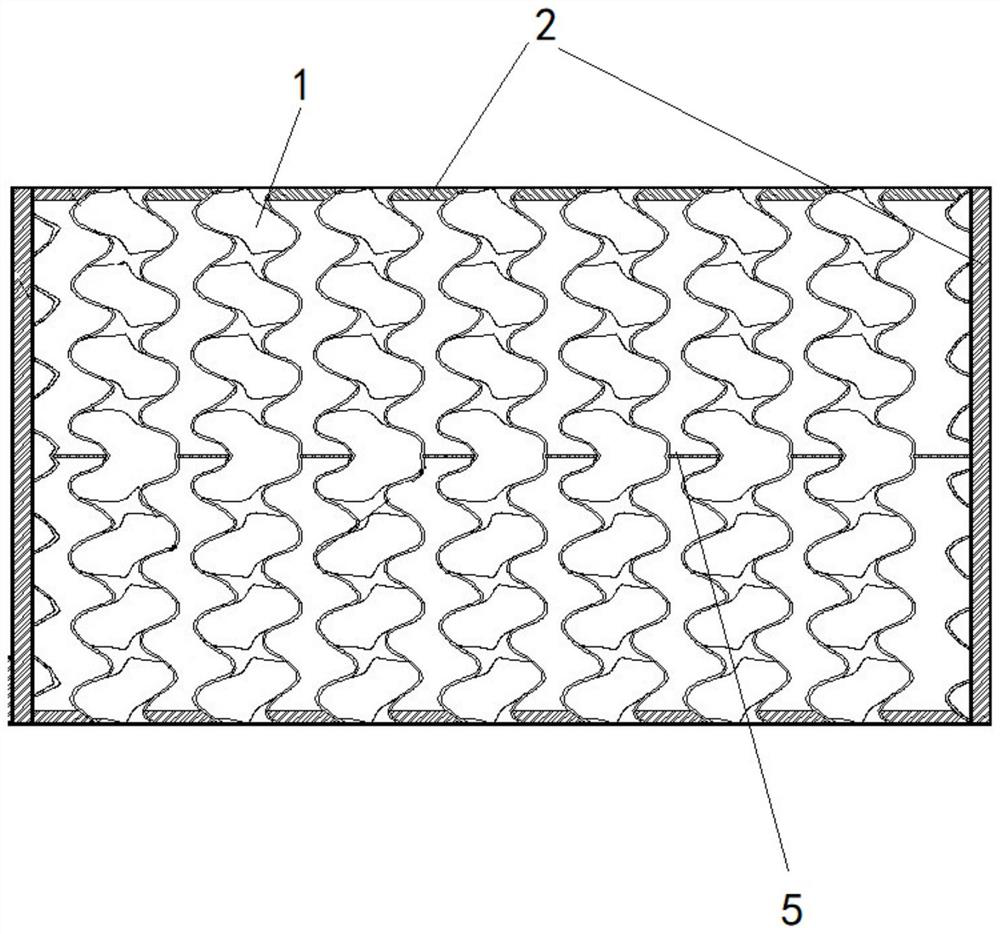

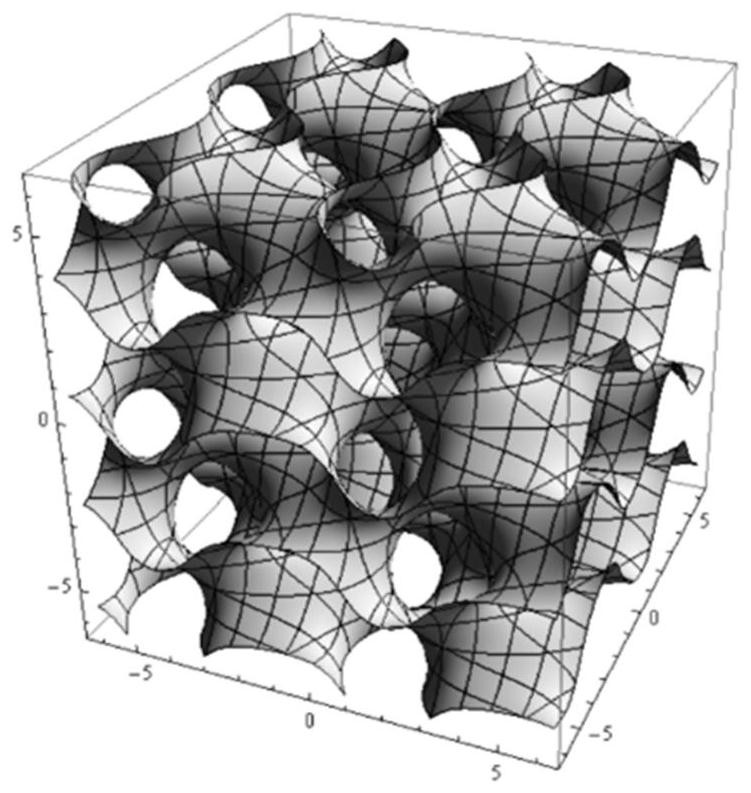

[0041] The core body 1 includes a first core body and a second core body, and a plurality of gas flow channels and liquid flow channels are provided in the first core body and the second core body, and the gas flow channels and the liquid flow channels are Both are 3D spiral channel structures; the extension length directions of the 3D spiral channels corresponding to the gas flow channel and the liquid flow channel are perpendicular to each other, forming a partitioned heat exchange structure. After the liquid to be heat-exchanged flows through the liquid channel of the first core, it can flow into the liquid flow channel of the second core through the peripheral guide components, so that the liquid to be heat-exchanged forms a U-shaped return flow direction, and the gas to be heat-excha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com