Flexible connecting piece and flexible connecting structure for preventing infilled wall from collapsing

A flexible connector and flexible connection technology, applied in the direction of walls, building components, building structures, etc., can solve the problems of out-of-plane collapse, loss, casualties, etc., and achieve the effect of avoiding out-of-plane collapse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

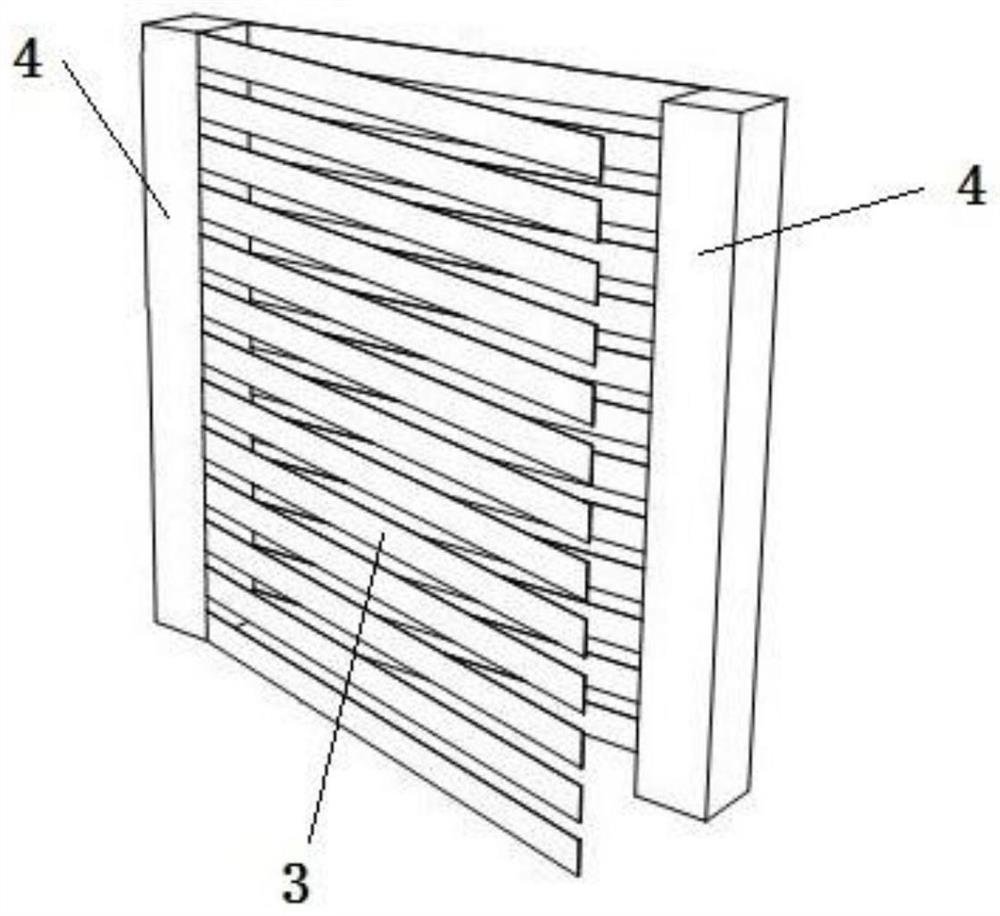

[0032] This embodiment provides a flexible connector, such as figure 1 As shown, in this embodiment, the flexible connector includes a plurality of flexible belts 3 and two fixed blocks 4, the plurality of flexible belts 3 are in two rows and are arranged side by side along the width direction of the flexible belt 3, and the two fixed blocks 4 The flexible belts 3 are arranged side by side at intervals along the length direction, and the two ends of the flexible belts 3 in one row are respectively fixedly connected with different fixing blocks 4, and the flexible belts 3 in the other row are fixed at one end on the same side with a fixing block 4 connection, the two fixing blocks 4 are respectively used for detachable connection with the frame column 1 located on both sides of the filling wall 2, and the space between the two rows of flexible strips 3 is used to accommodate the filling wall 2, and both sides of the filling wall 2 are provided with A number of flexible belts 3 ...

Embodiment 2

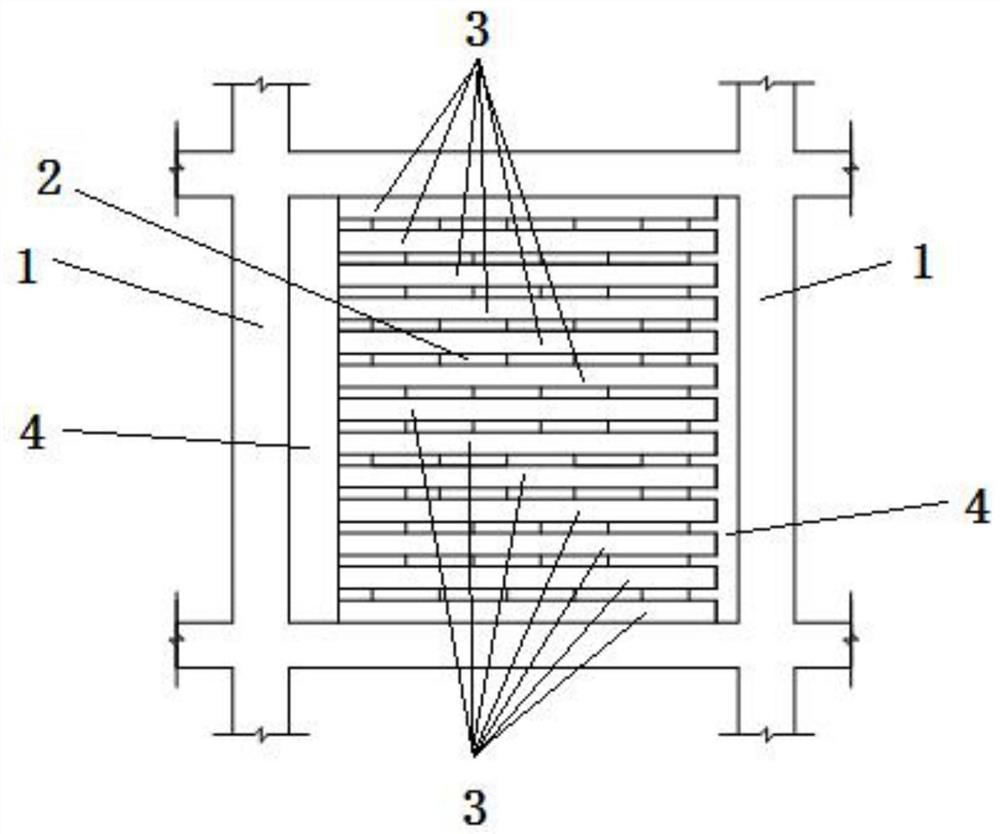

[0037] This embodiment provides a frame-filled wall 2 structure, such as Figure 2~3 As shown, in this embodiment, the frame filling wall 2 structure includes the frame, the filling wall 2 and the flexible connector in Embodiment 1. The frame includes two frame columns 1, and the two frame columns 1 are arranged vertically at intervals. Two fixed blocks 4 are vertically spaced apart, and the two opposite surfaces on the two frame columns 1 are respectively detachably connected with the two fixed blocks 4, and the filling wall 2 is filled between the two fixed blocks 4, and is located in two rows of flexible belts. 3, the two ends of the two rows of flexible belts 3 are respectively fixedly connected with different fixed blocks 4, and both sides of the filling wall 2 are provided with several flexible belts 3 arranged side by side in the vertical direction, and the flexible belts 3 The two ends of the two fixed blocks 4 are detachably connected to the frame columns 1 located at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com