Glue inlet device with latent side sprue

A side gate and glue feeding technology is applied in the field of glue feeding devices for latent side gates, which can solve the problems of mold sticking and casting head flying.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following is further described in detail through specific implementation methods:

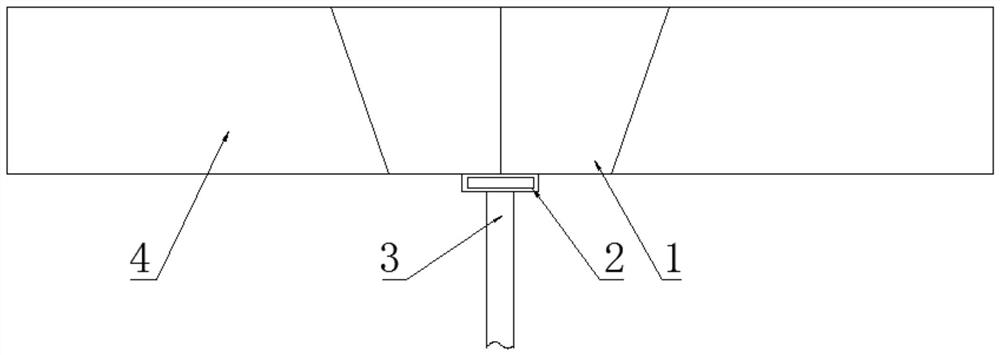

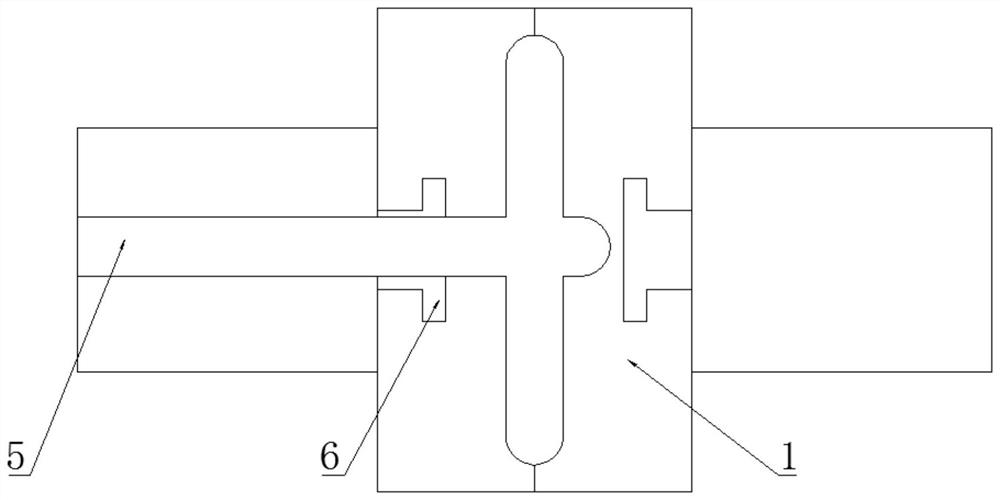

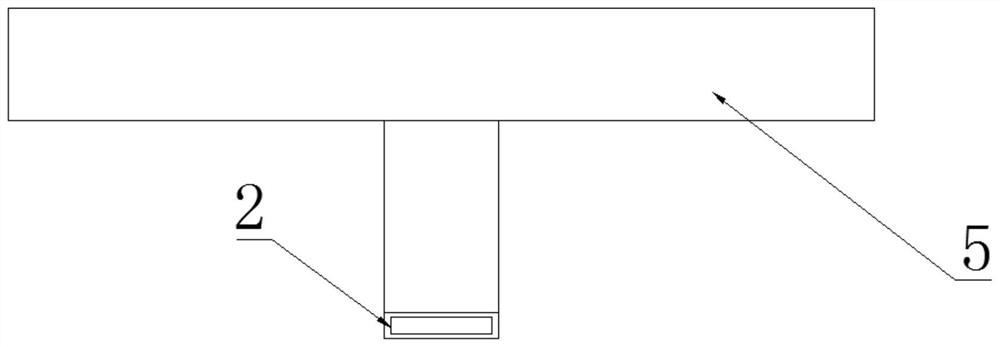

[0019] The reference signs in the drawings of the description include: gate plate 1 , side gate 2 , ejector pin 3 , punch 4 , runner 5 , and T-shaped plate 6 .

[0020] Examples such as figure 1 , figure 2 and image 3 As shown, a glue feeding device for a latent side gate includes a punch 4 and a die, the two sides of the punch 4 are welded with suspension rings, and a molding cavity is provided between the die and the punch 4 (shown in the figure ). The middle part of the punch 4 is provided with an installation port, and the installation port is provided with a runner 5 and a ejector pin 3 sequentially from top to bottom. The gate 2 and the side gate 2 communicate with the molding cavity. The inner wall of the installation port is inclined downward toward the ejector rod 3, and the inner wall of the installation port is correspondingly welded with a T-shaped plate 6. The sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com