Surface acoustic wave filter and forming method thereof

A surface acoustic wave and filter technology, applied in the field of surface acoustic wave filters and their formation, can solve problems such as difficulty in improving device production efficiency, production costs, SAW filter processing technology is difficult, and preparation costs are high, so as to reduce implementation The effect of difficulty, improving Q value and simplifying process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

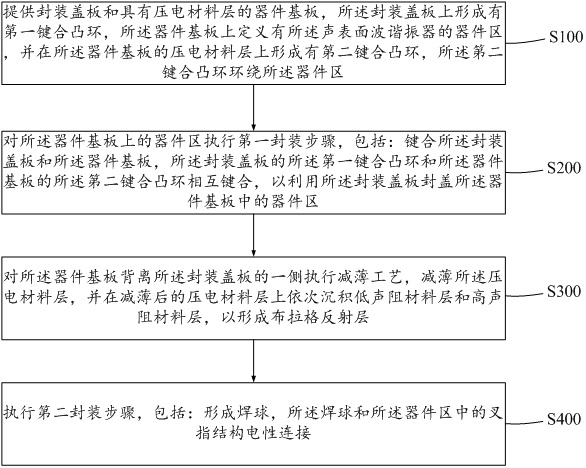

[0046] The core idea of the present invention is to provide a method for forming a surface acoustic wave filter, which can combine the device processing technology and packaging technology of the surface acoustic wave filter. For details, please refer to figure 1 As shown, the forming method includes:

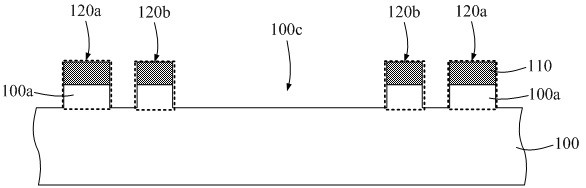

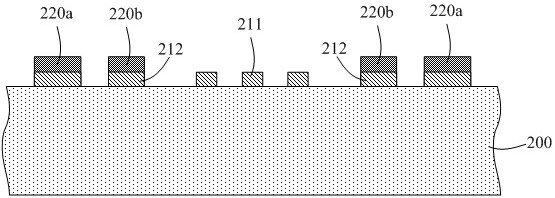

[0047] Step S100, providing a package cover plate and a device substrate having a piezoelectric material layer, a first bonding convex ring is formed on the package cover plate, and a device region of the surface acoustic wave filter is defined on the device substrate, And a second bonding protruding ring is formed on the piezoelectric material layer of the device substrate, and the second bonding protruding ring surrounds the device region;

[0048] Step S200, performing a first packaging step on the device region on the device substrate, including: bonding the packaging cover plate to the device substrate, so as to use the packaging cover plate to cover the devices in the de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com