Energy accumulator and energy-saving system utilizing waste heat of engine tail gas

An energy-saving system and accumulator technology, which is applied to engine components, combustion engines, machines/engines, etc., and can solve problems such as the reduction of the working efficiency of accumulators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with accompanying drawing.

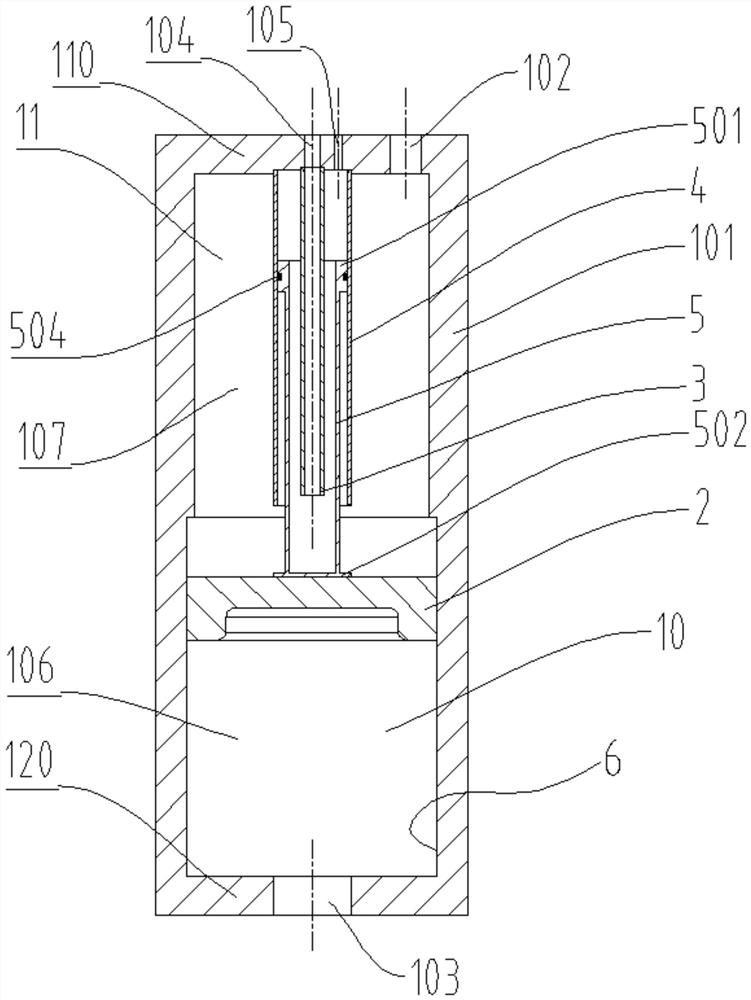

[0024] Such as figure 2 As shown, an accumulator utilizing waste heat from engine exhaust includes an accumulator body 1; the accumulator body 1 includes a cylinder 101, a piston assembly 2 and a cooling assembly;

[0025] The interior of the cylinder 101 has an axially extending stepped cavity 6, and an upper end cover 110 and a lower end cover 120 are respectively fixedly connected to the two ends of the stepped cavity 6; The lower large-diameter section 10 is formed, and the inner wall of the stepped chamber 6 is smooth.

[0026] The piston assembly 2 is a disc-shaped assembly whose size matches the size of the large-diameter section 10, and is assembled in the large-diameter section 10 in a sliding and sealing manner, and the piston assembly 2 can slide along the axial direction of the stepped chamber 6; The stroke of the piston assembly 2 is limited by the lower end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com