FRP connecting part for composite heat-preserving integrated plate and forming method thereof

A composite thermal insulation and forming method technology, applied in thermal insulation, building components, walls, etc., can solve the problems of easy corrosion, reduced wall thermal insulation performance, cold and thermal bridges, etc., and achieve stable anchoring performance and excellent mechanical indicators.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

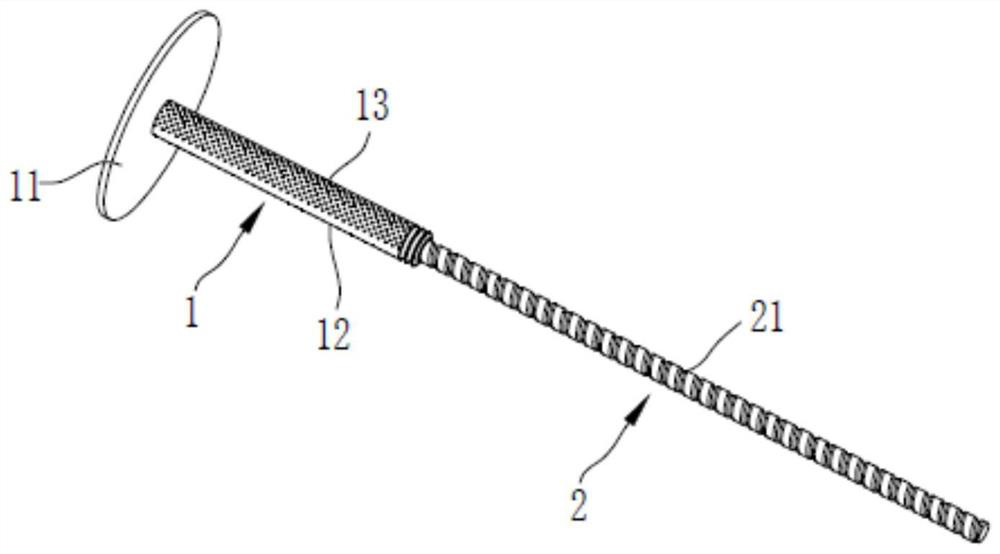

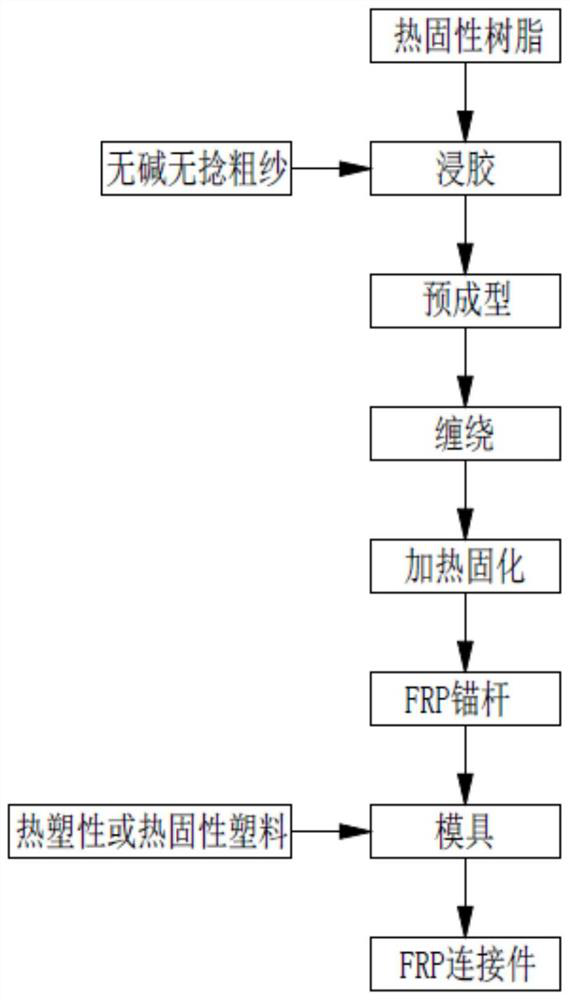

[0028] Such as figure 1 As shown, the FRP connecting piece for the composite thermal insulation integrated board is composed of a fixed disc seat 1 made of plastic material and an FRP anchor rod 2 made of thermosetting material; the material of the fixed disc seat 1 preferably adopts native polyamide (PA6 / PA66), polyamide Ethylene (PE) or polypropylene (PP) should not be recycled materials.

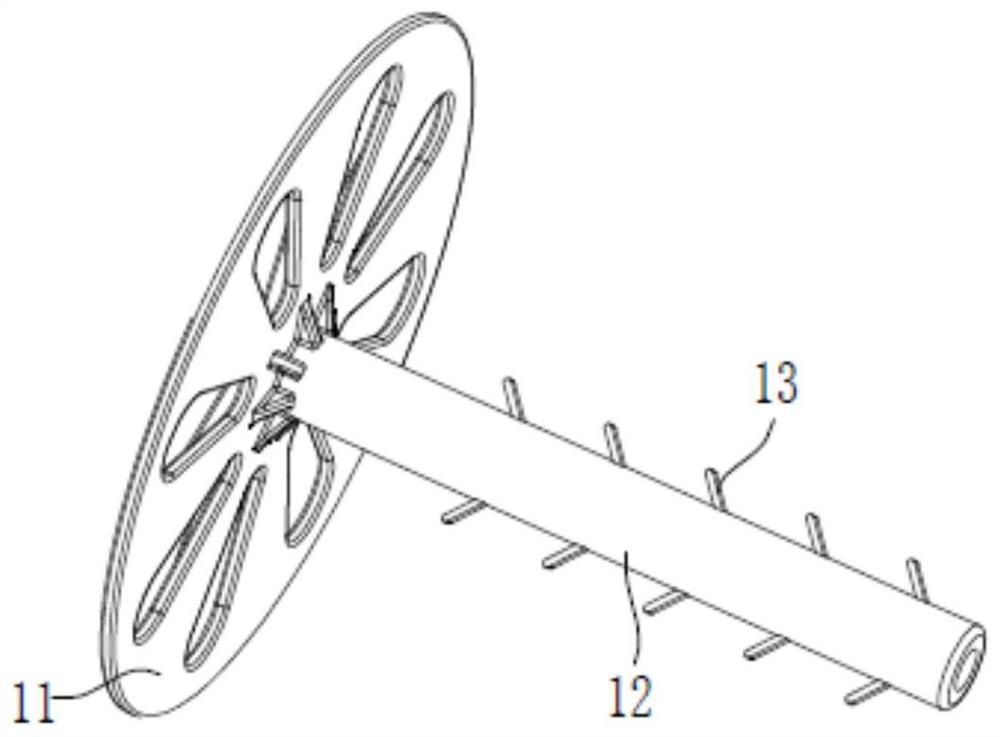

[0029] The fixed disk seat 1 includes a circular disk body 11 and a connecting portion 12 integrally formed with the disk body 11. The fixed disk seat 1 is directly injection molded on one end of the FRP anchor rod 2; the fixed disk A non-slip structure 13 is formed on the connecting portion 12 of the seat 1, refer to figure 1 , The non-slip structure 13 can be convex and concave, of course, it can also be like figure 2 As shown, the use of anti-skid structures such as barbs should fall within the protection scope of the present invention;

[0030] The rod body of the FRP anchor rod 2 is form...

Embodiment 2

[0044] reference Figure 5 The structure of this embodiment is basically the same as that of the first embodiment. The only difference is that the processing method of the anchoring groove 21 on the FRP anchor rod 2 is different. In this embodiment, the anchoring groove 21 is in the FRP anchor rod 2. After heat curing, it is secondary molded by machining process. When the depth and spacing of the anchoring groove are the same, the anchoring performance is basically the same as that of the first embodiment of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com