Splicing unit, splicing structure and leather goods making method

A technology of splicing unit and production method, which is applied in the direction of composite leather, etc., which can solve the problems of obvious splicing marks, no waterproof effect at the splicing place, and glue overflow, so as to improve efficiency and output, maintain the overall appearance and shape, and simplify the production process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

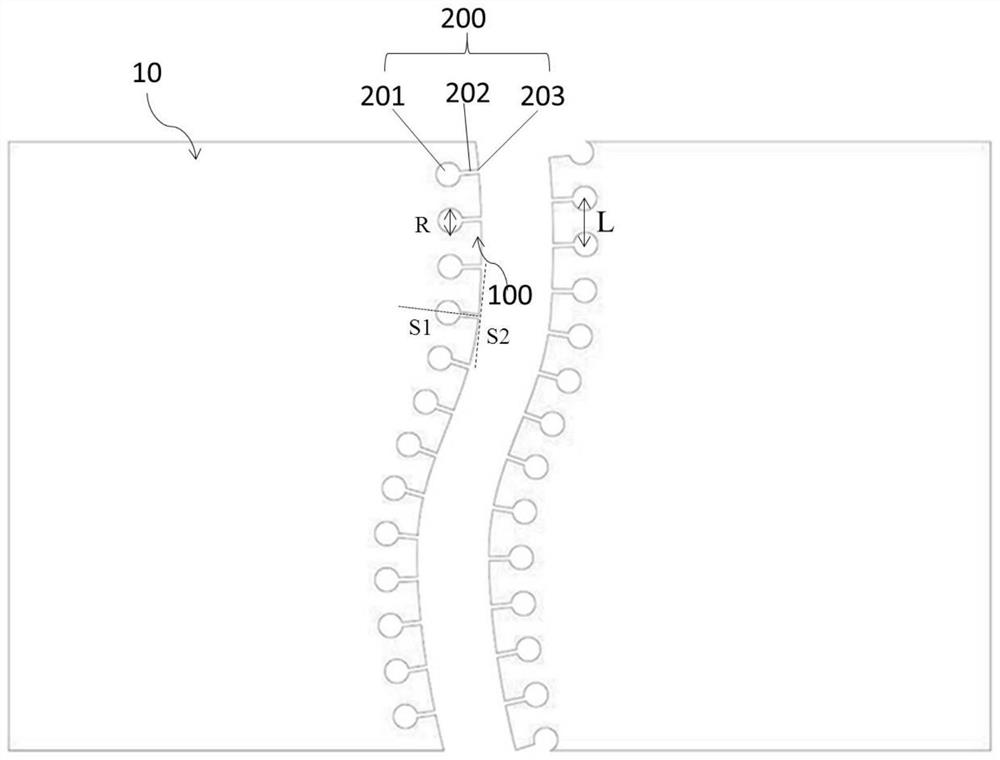

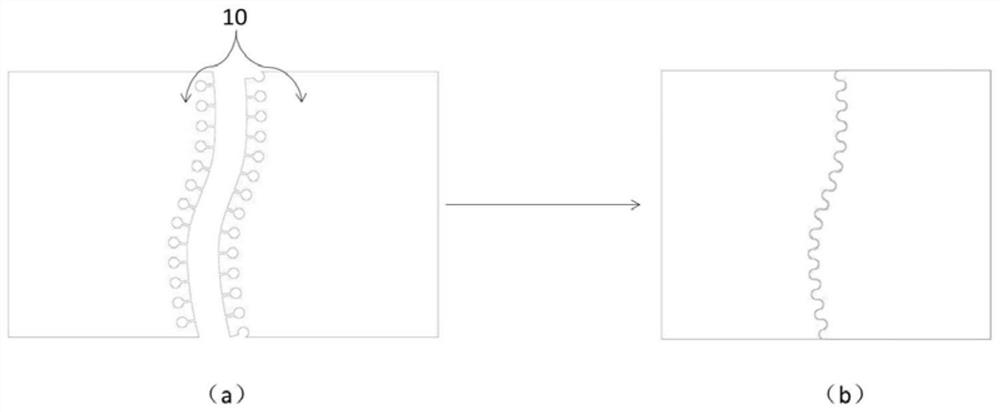

[0031] Embodiment 1: A splicing unit 10 provided by the present invention includes a splicing edge 100 and several first splicing elements 200 arranged along the splicing edge 100. The first splicing element 200 includes a first splicing hole 201 and a first splicing hole 201 from the first splicing hole. The edge of 201 extends toward the first notch 202 of the splicing edge 100, the intersection of the first notch 202 and the splicing edge 100 is the first interface 203, and the distance between adjacent first splicing holes 201 is the same as the diameter of the first splicing hole 201 .

[0032] In an optional embodiment of the present invention, the splicing unit 10 is used as the structure to be spliced. In this embodiment, the splicing edge 100 of the splicing unit 10 is a straight line, and the first incision 202 and the splicing edge 100 are in a T-shaped structure. , that is, the first notch 202 is perpendicular to the splicing edge 100, and the intersection with the...

Embodiment 2

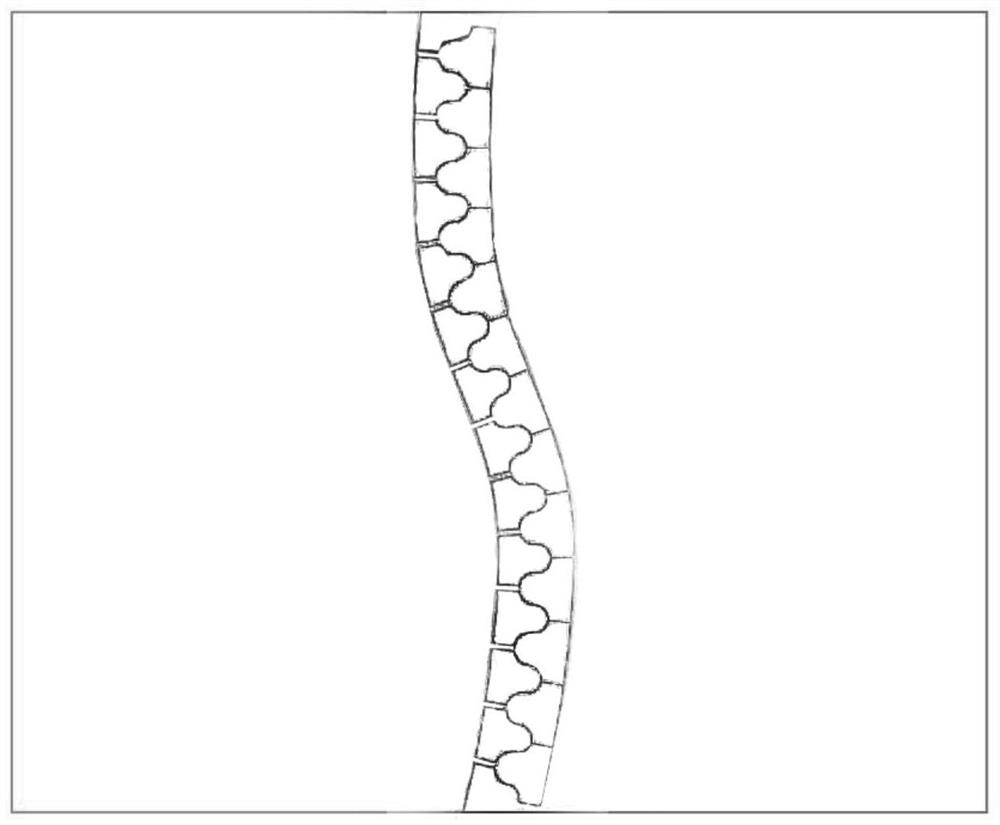

[0039] Embodiment 2: as Figure 4 As shown, the splicing unit 10 in the present invention can be a polygonal structure, and each edge of the splicing unit 10 of the polygonal structure is used as a splicing edge 100, and the splicing unit 10 can be expanded around and spliced into any shape.

[0040]When the splicing unit 10 is a polygonal structure, the vertex of the splicing unit 10 is correspondingly provided with a second splicing element 300, and the second splicing element 300 includes a second splicing hole 301 and an edge extending toward the corresponding vertex along the edge of the second splicing hole 301. The second notch 302, the intersection of the second notch 302 and the splicing edge 100 is the second interface 303, and the setting principle of the second notch 302 is the shortest distance from the second splicing hole 301 to the vertex of the polygon, that is, the second interface 303 as the second splicing hole 301. The cutout 302 and the second splicing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com