High-strength high-water-absorption degradable plugging agent and preparation method thereof

A high-water absorption and high-strength technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of easy residue accumulation, insufficient and incomplete, and the leakage plugging agent cannot self-degrade and degrade, so as to avoid gelation. Sticky wall, good effect, avoids the effect of solvation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

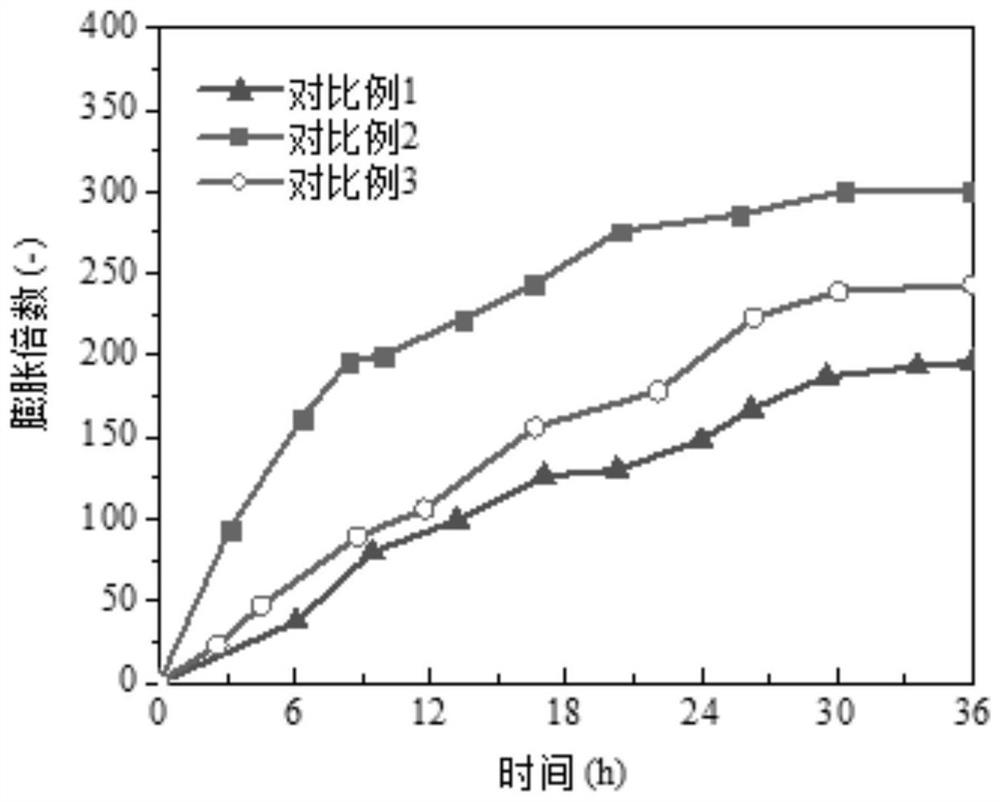

Image

Examples

Embodiment 1

[0046] A high-strength, high-water-absorbing and degradable leak-stopping agent A includes vinyl monomers, hydrophilic auxiliary agents, modified starches, crosslinking agents, initiators, inorganic reinforcing agents, degradation aids, and degradation activators. Based on the total weight of the plugging agent, the content of ethylenic monomer is 25%, the content of hydrophilic auxiliary agent is 15%, the content of modified starch is 30%, the content of crosslinking agent is 0.15%, and the content of initiator is 1.5%. The content of the inorganic reinforcing agent is 3 percent; the degradation aid is 0.03 percent of the mass of the modified starch, and the degradation activator is 0.003 percent of the mass of the degradation aid. Acrylamide and aminoethyl (meth)acrylate are selected as alkenyl monomers, the mass ratio of the two is 2:1, the hydrophilic auxiliary agent is methacrylic acid, the crosslinking agent is sodium p-styrenesulfonate, and the initiator is persulfuric a...

Embodiment 2

[0053] A high-strength, high-water-absorbing and degradable leak-stopping agent B includes vinyl monomers, hydrophilic auxiliary agents, modified starches, crosslinking agents, initiators, inorganic reinforcing agents, degradation aids, and degradation activators. Based on the total weight of the plugging agent, the content of ethylenic monomer is 25%, the content of hydrophilic auxiliary agent is 15%, the content of modified starch is 30%, the content of crosslinking agent is 0.15%, and the content of initiator is 1.5%. The content of the inorganic reinforcing agent is 4%; the degradation aid is 0.06% of the quality of the modified starch, and the degradation activator is 0.005% of the quality of the degradation aid; the ethylenic monomer is selected from acrylamide and aminoethyl (meth)acrylate, The two mass ratios are 2:1, the hydrophilic additive is methacrylic acid, the crosslinking agent is sodium p-styrene sulfonate, the initiator is ammonium persulfate / sodium bisulfite ...

Embodiment 3

[0060] A high-strength, high-water-absorbing and degradable leak-stopping agent C includes vinyl monomers, hydrophilic auxiliary agents, modified starches, crosslinking agents, initiators, inorganic reinforcing agents, degradation aids, and degradation activators. Based on the total weight of the plugging agent, the content of ethylenic monomer is 30%, the content of hydrophilic auxiliary agent is 18%, the content of modified starch is 35%, the content of crosslinking agent is 0.5%, and the content of initiator is 1.5%. , the content of the inorganic reinforcing agent is 3%; the degradation aid is 0.03% of the mass of the modified starch, and the degradation activator is 0.003% of the mass of the degradation aid; the alkenyl monomer is selected from acrylamide and (meth)aminoethyl acrylate , the mass ratio of the two is 2:1, the hydrophilic auxiliary agent is methacrylic acid, the crosslinking agent is sodium p-styrene sulfonate, the initiator is ammonium persulfate / sodium bisu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com