Preparation method of high-purity butylphthalide

A butylphthalide and high-purity technology, applied in the field of preparation of butylphthalide, can solve the problems of difficulty in separation and purification by column chromatography, long reflux time, insufficient product purity, etc., and achieves mild and controllable preparation process and product impurity content. Low, stable effect of synthesis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

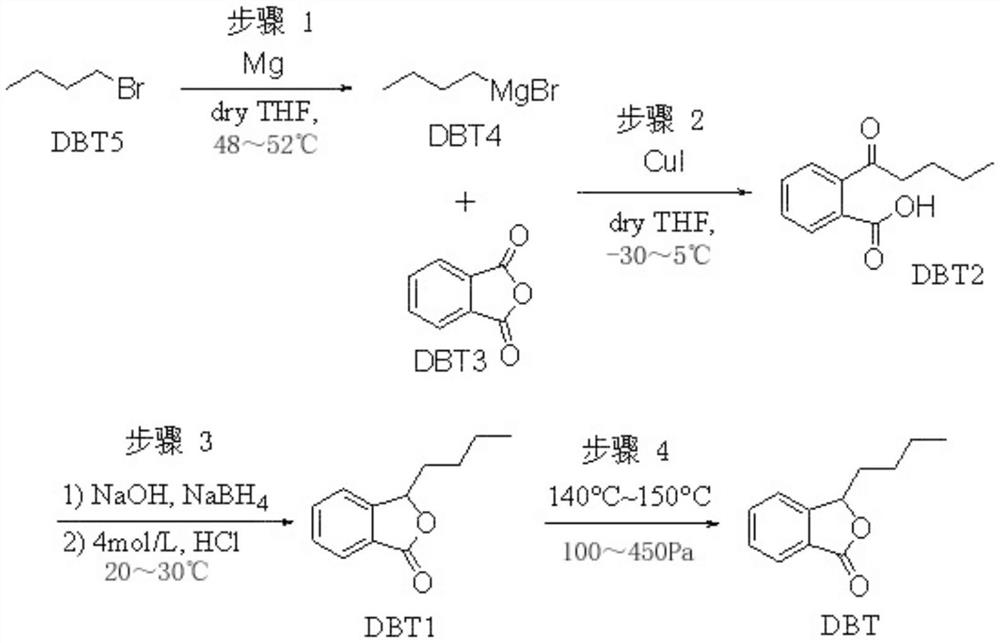

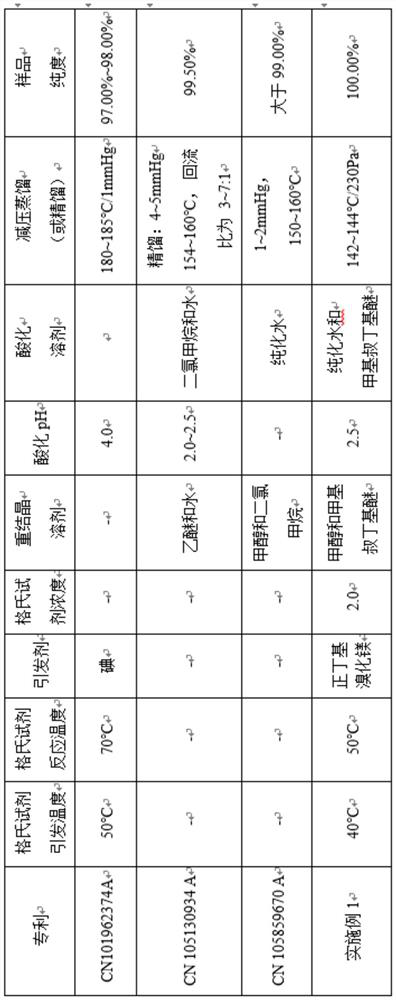

[0034] The invention provides a kind of preparation method of high-purity butylphthalide, and reaction process is as follows:

[0035]

[0036] The HPLC described in the examples is measured by the area normalization method.

Embodiment 1

[0038] A preparation method of high-purity butylphthalide, comprising the steps of:

[0039] Step 1: Preparation of n-butylmagnesium bromide

[0040] Add 1.192 kg (49 mol) of magnesium chips and 10.2 kg (141.7 mol) of anhydrous tetrahydrofuran into the 50 L reactor, and replace with nitrogen three times under stirring, and then protect the reaction and post-treatment process under nitrogen. Stir and heat up so that the temperature in the reactor reaches 40°C and stabilizes. Stirring was stopped, and 350 mL of a mixed solution of n-butylmagnesium bromide and anhydrous tetrahydrofuran with a molar concentration of 2 mol / L was added to the reactor, and stirring was started and 6.4 kg (46.7 mol) of n-bromobutane and anhydrous tetrahydrofuran were added dropwise. The mixed solution of water tetrahydrofuran 6.4kg (88.9mol), observe that the internal temperature of the reactor rises, and the solution is produced with bubbles, indicating that the reaction is triggered, continue to slow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com