Sludge deep dehydration coupled biomass pyrolysis system and method thereof

A biomass pyrolysis and deep dehydration technology, applied in the field of environmental protection, can solve the problems of restricting promotion, high investment and operation costs, secondary pollution of flue gas, etc., to reduce investment and operation costs, improve energy utilization efficiency, and achieve stable operation. reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] This embodiment provides a method for deep sludge dehydration coupled with biomass pyrolysis.

[0066] A method for deep sludge dehydration coupled with biomass pyrolysis, comprising the following steps:

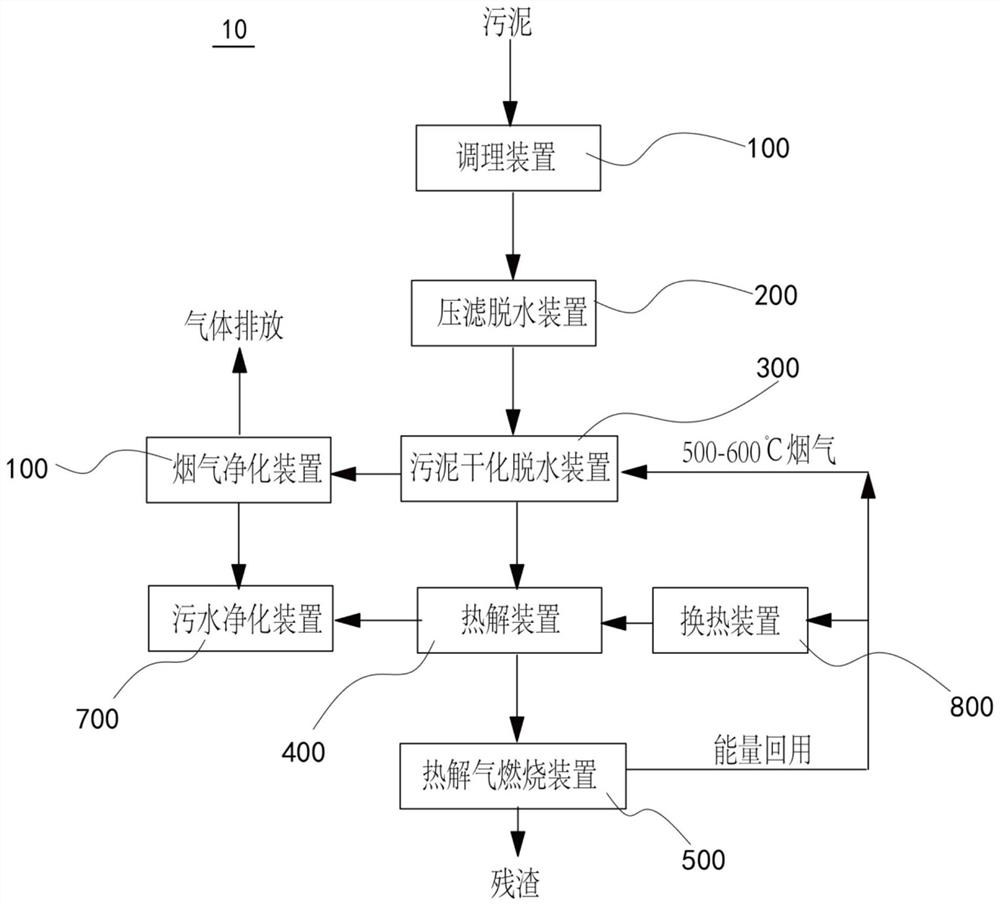

[0067] see figure 1 As shown, the sludge enters the conditioning device, and the cell wall in the sludge is broken and the suspended matter is flocculated through conditioning by adding medicine, so as to improve the sludge dehydration efficiency.

[0068] The conditioned sludge enters the filter press dewatering device 200 to realize press filter dehydration to form press filter sludge, the moisture content of the filter cake after the sludge press filter dewatering is reduced to 55%, and the filter press sludge enters the sludge drying and dewatering device 300 , the filtrate from the filter press dehydration device 200 enters the sewage treatment device 700 and is discharged after reaching the standard.

[0069] The sludge dehydration and drying device performs d...

Embodiment 2

[0074] This embodiment provides a method for deep sludge dehydration coupled with biomass pyrolysis.

[0075] A method for deep sludge dehydration coupled with biomass pyrolysis, comprising the following steps:

[0076] see figure 1 As shown, the sludge enters the conditioning device, and the cell wall in the sludge is broken and the suspended matter is flocculated through conditioning by adding medicine, so as to improve the sludge dehydration efficiency.

[0077] The conditioned sludge enters the filter press dewatering device 200 to realize press filter dehydration to form press filter sludge. Preferably, the moisture content of the filter cake after sludge press filter dewatering is reduced to 60%, and the filter press sludge enters the sludge drying The filtrate of the dehydration device 300 and the filter press dehydration device 200 enters the sewage treatment device 700 and is discharged after reaching the standard.

[0078] The sludge dehydration and drying device p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com