A chemical liquid agent filling system

A filling system, a technology for chemical liquids, applied in liquid bottling, liquid processing, packaging, etc., can solve the problems of waste, lower qualification rate, and large contact between fluid and air

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings.

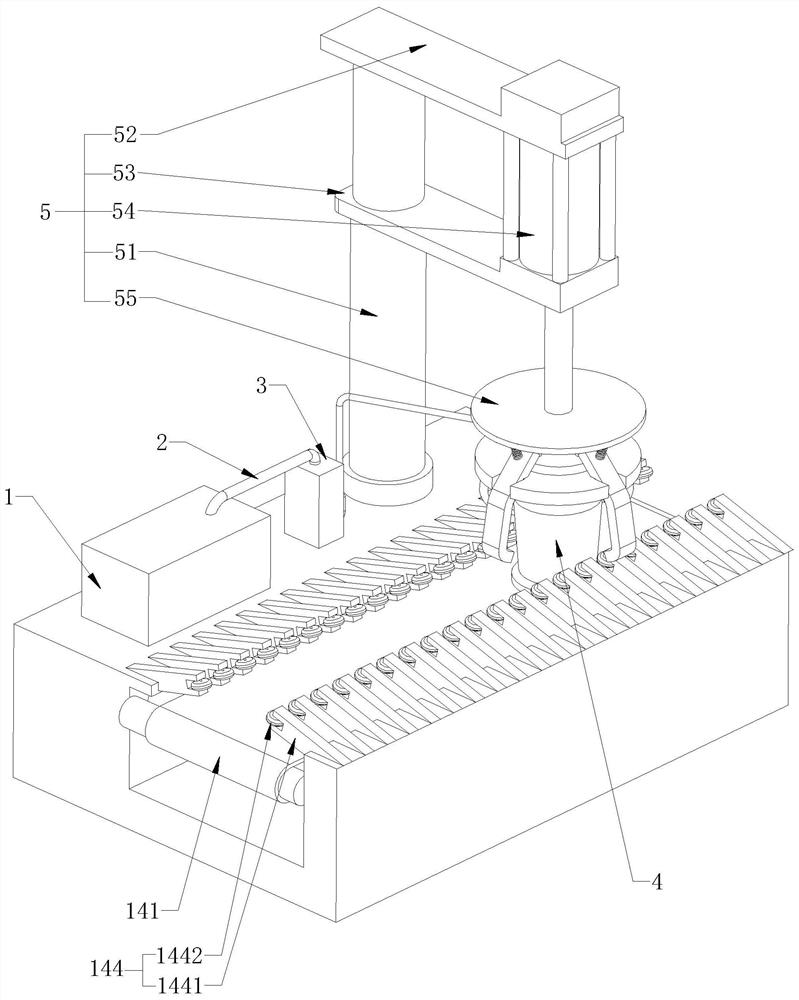

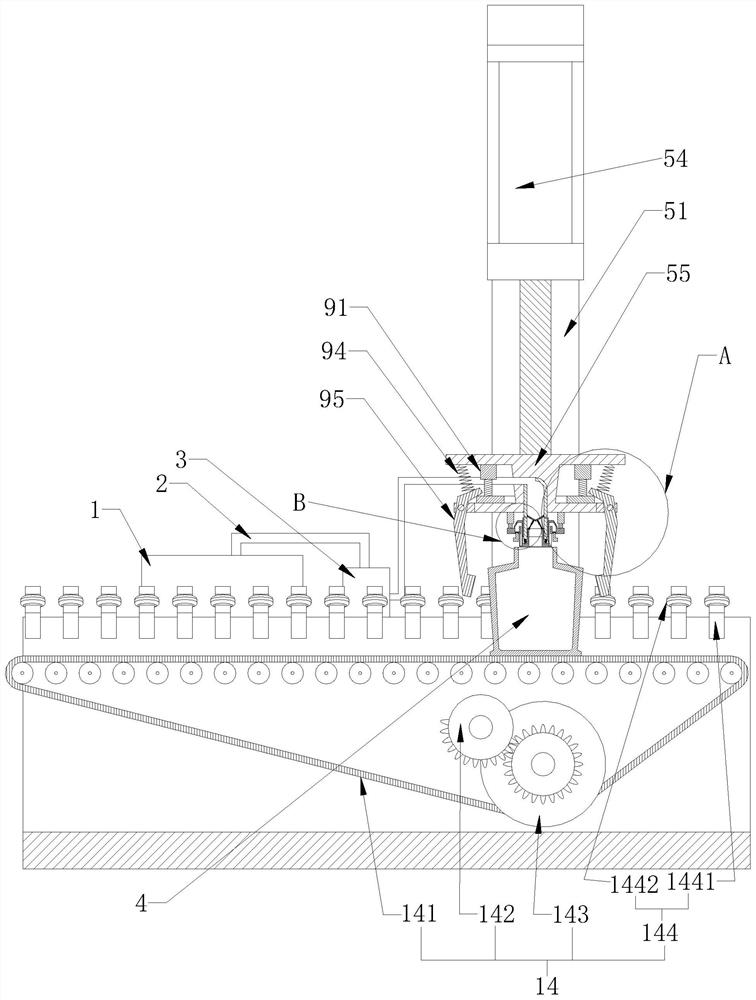

[0034] refer to figure 1 As shown, it is a chemical liquid medicine filling system disclosed in the present invention, which includes a feeding box 1, a delivery pipe 2, a liquid pump 3 and a liquid bottle 4, and the system also includes a fixing frame 5, a splash prevention device 6 and an airtight Device 7, fixed frame 5 is arranged on the workbench and is installed for splash-proof device 6 and air-tight device 7; Splash-proof device 6 prevents the liquid of input from splashing, and air-tight device 7 guarantees better air-tightness when injecting liquid, improves quality .

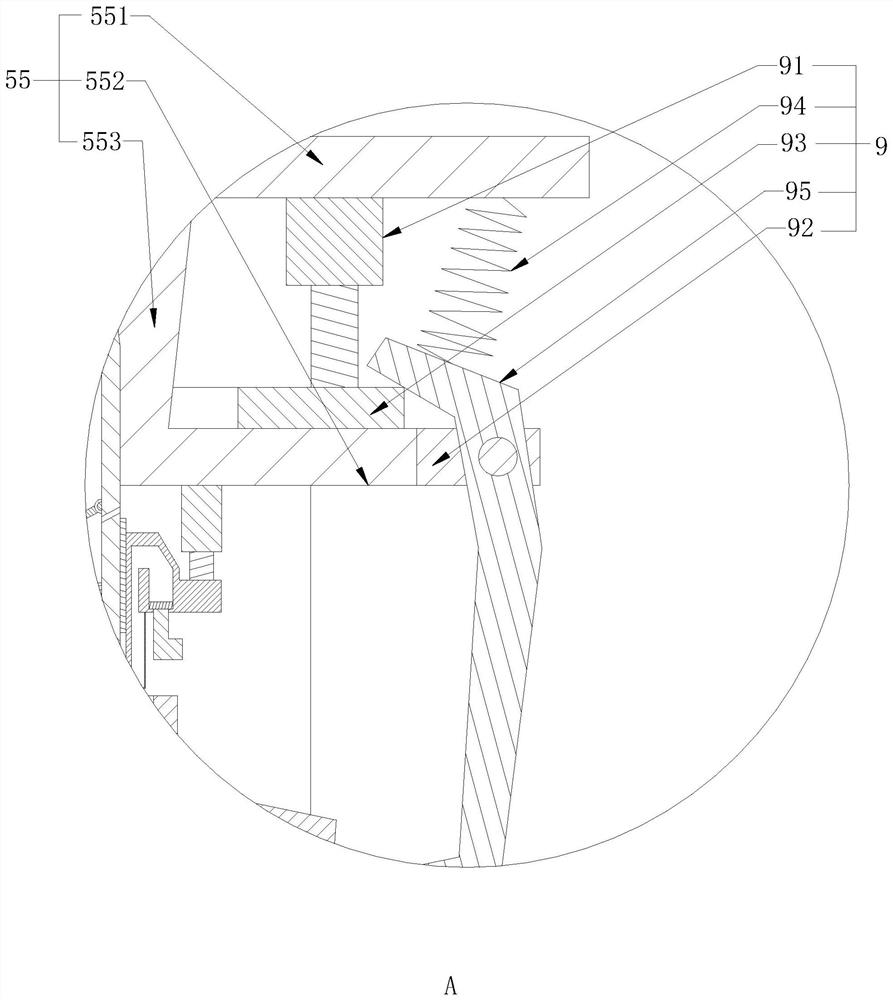

[0035] Continue to refer to figure 1 As shown, the fixed frame 5 includes a support column 51, an upper mounting plate 52, a lower mounting plate 53, a hydraulic cylinder 54, and an I-shaped disc 55; Made of metal material with a certain strength, use 6 M8×20 bolts and nuts to ver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com