Automatic welding machine for square pipes and gaskets

An automatic welding machine and gasket technology, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of low welding accuracy, low degree of automation, and lack of rolling properties, so as to reduce labor input and save money. Production space and cost, the effect of reducing the floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

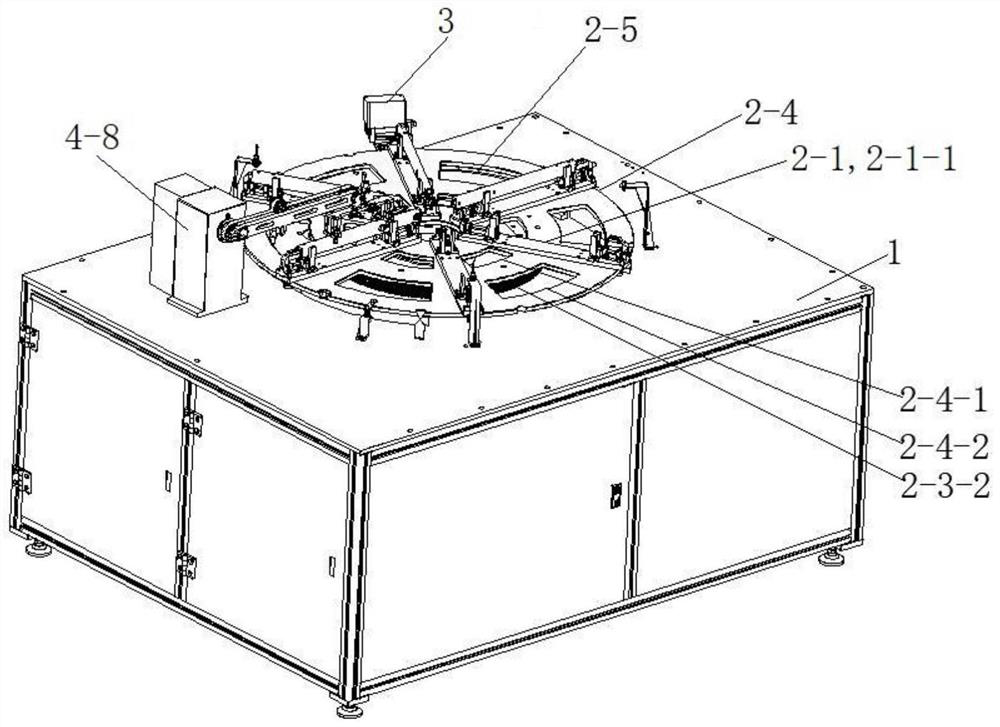

[0047] See Figure 1 to Figure 12 , the square tube and gasket automatic welding machine of the present embodiment includes an operation table 1, and a rotary table 2 rotatably mounted on the operation table 1, and an automatic gasket feeding device 5, a pad A sheet detection device, a square tube automatic feeding device 4, a square tube detection device, a welding device 3 and an automatic unloading device 6, and a control panel 7 is also fixedly installed on the console 1. The welding device 3 adopts a laser welding machine. The control panel 7 adopts a touch screen and is electrically connected with the rotary table 2, the square tube automatic feeding device 4, the gasket automatic feeding device 5 and the weldment automatic unloading device 6, and is used to control the startup and shutdown of each device. Easy to operate.

[0048] See Figure 1 to Figure 4 , The rotary table 2 includes a welding assembly mechanism 2-1, a first driving mechanism 2-2, a transmission me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com