High-safety claw forging equipment

A high-security, hook-claw technology, applied in metal processing equipment, hooks, manufacturing tools, etc., can solve the problems of large tool damage, difficult edge removal, and increased hardness of forging blocks, achieving the effect of less heat loss and convenient removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

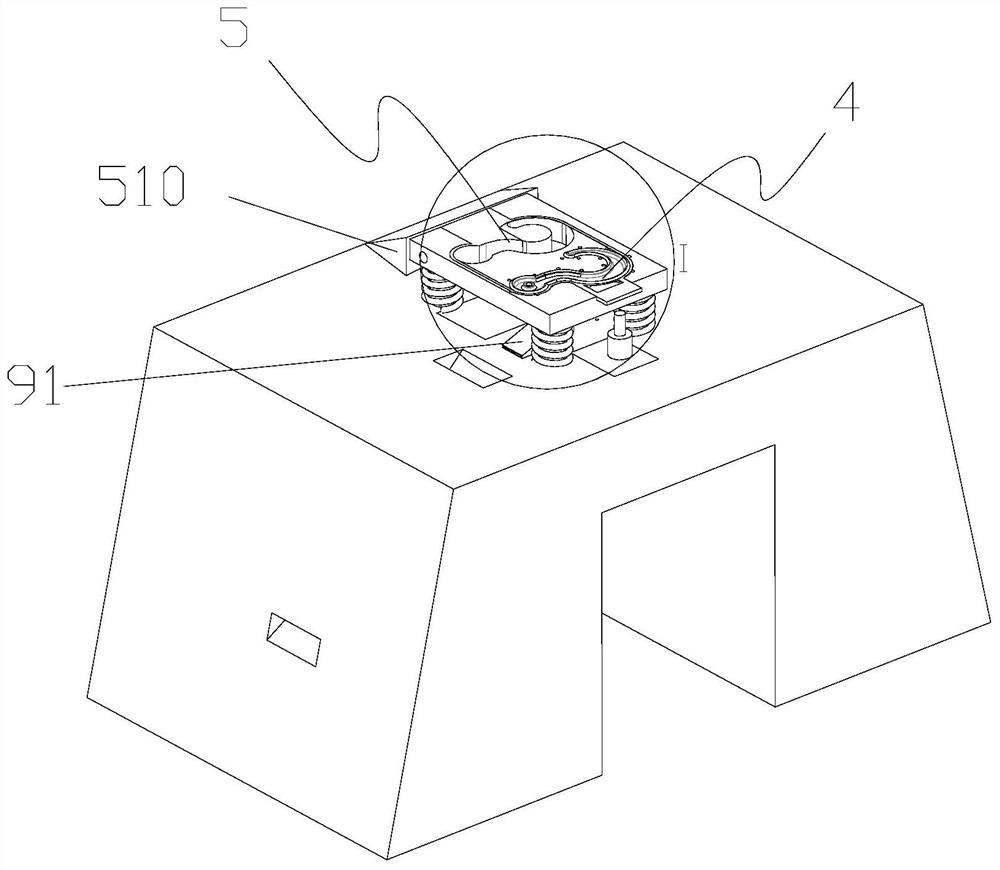

[0024] Such as Figure 1-11 As shown, a high-safety claw forging equipment includes a base 1, a frame 2, and a forging device 3; the base 1 is set on the ground, the frame 2 is set on the base, and the forging device 3 is set on the On the frame; the forging device 3 includes a hydraulic rod 31, a hydraulic hammer 32, a first slide rail 33, an upper die 34, a lower die 35, a forging structure 4, an edge removal structure 5, a shifting structure, and a first cleaning structure 6. The second cleaning structure 7; the hydraulic rod 31 is arranged on the frame, the hydraulic hammer 32 is arranged on the hydraulic rod, the first slide rail 33 is arranged on the frame, and the first slide rail is arranged on the On both sides of the frame, the upper mold 34 is arranged under the hydraulic hammer, the lower mold 35 is arranged on the base, the forging structure 4 is arranged on the lower mold, and the edge removal structure 5 is arranged on one side of the forging structure, The dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com