A small-pore molecular sieve-loaded bimetal material for removing nitrogen oxides from diesel vehicle exhaust at low temperature, its preparation method and application

A nitrogen oxide and molecular sieve technology, applied in separation methods, molecular sieve catalysts, chemical instruments and methods, etc., can solve the problem of no Chinese name, and achieve the effect of inhibiting agglomeration, improving NOx removal efficiency, and improving high temperature water resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

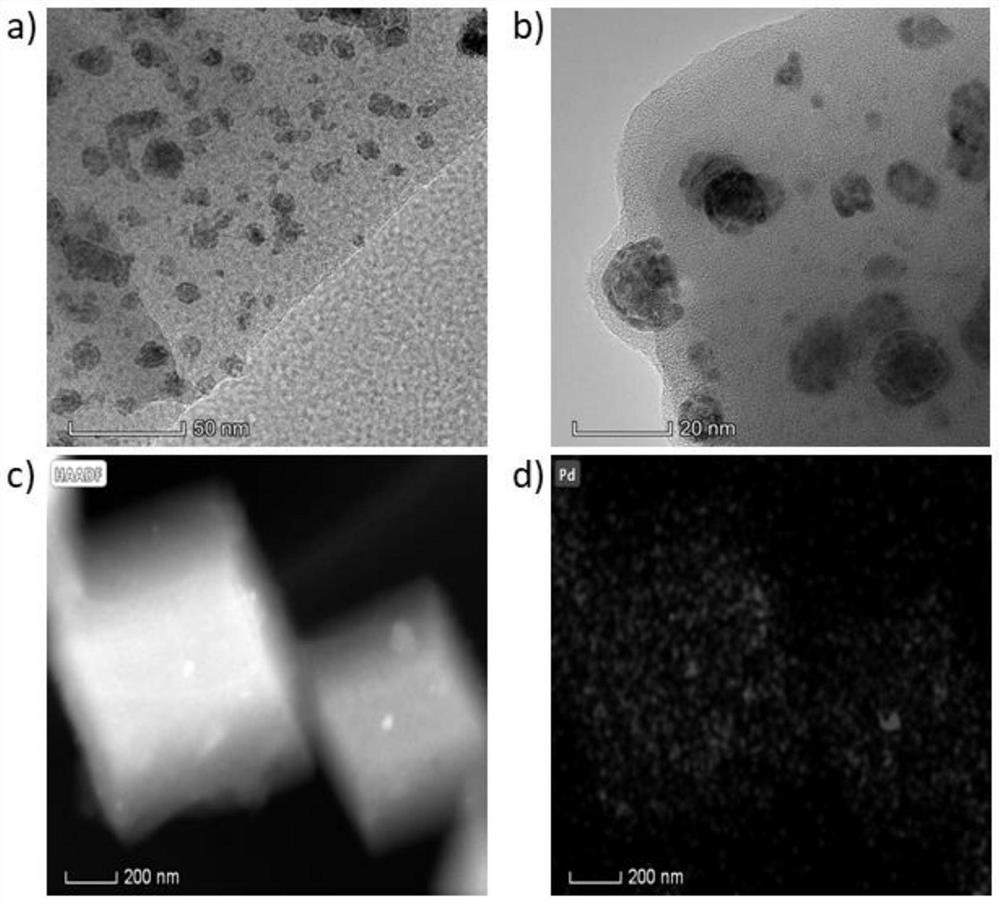

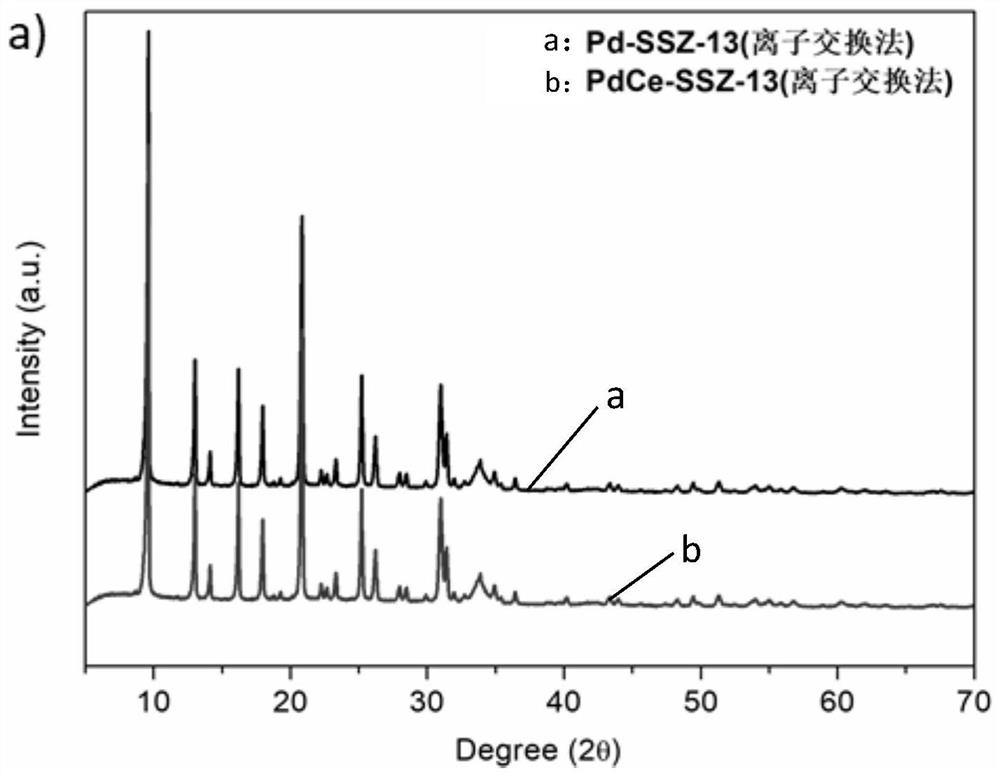

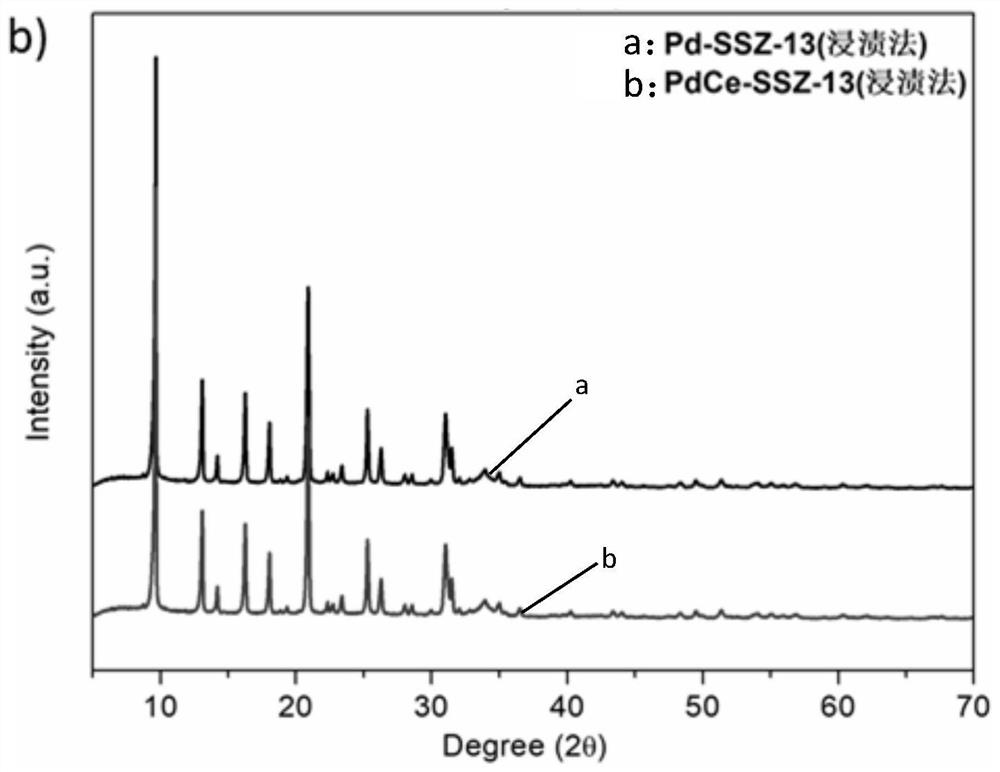

Image

Examples

Embodiment 1

[0035] (1) NH 4 - Preparation of SSZ-13 catalyst

[0036] (1-1) Weigh 5~20g of commercial H-SSZ-13 and place it in a tube furnace, calcined at 520 °C for 12 h under dry air conditions; add 20 g of ammonium sulfate to an appropriate amount of water (the solution concentration is 8 mol) / L, solution volume 250mL), stir for a few minutes under ultrasonic conditions until the ammonium nitrate is completely dissolved; weigh 40g of H-SSZ-13 molecular sieves after high temperature calcination and add them to the above-mentioned ammonium sulfate solution, then the mixed solution is moved to magnetic stirring The mixture was stirred at room temperature for 2.5 h (800 r / min), and the stirred mixture was filtered to obtain a white solid, which was washed several times with deionized water. After repeating the above process 3 times, the obtained white solid was placed in an oven and dried at 160 °C for 20 h to obtain NH 4 -SSZ-13.

[0037] (1-2) The preparation method of Pd-SSZ-13 (ion...

Embodiment 2

[0044] (1) NH 4 - Preparation of SSZ-13 catalyst

[0045] (1-1) Weigh 5~20g of commercial H-SSZ-13 and place it in a tube furnace, calcined at 520 ℃ for 12h under dry air conditions; add 20g of ammonium sulfate to an appropriate amount of water (solution concentration is 8 mol / L, solution volume 250mL), stir for several minutes under ultrasonic conditions until ammonium nitrate is completely dissolved; weigh 40g of H-SSZ-13 molecular sieves after high-temperature calcination and add them to the above-mentioned ammonium sulfate solution, then move the mixed solution to a magnetic stirrer The mixture was stirred at room temperature for 2.5 h (800 r / min), and the stirred mixture was filtered to obtain a white solid, which was washed several times with deionized water. After repeating the above process 3 times, the obtained white solid was placed in an oven and dried at 160 °C for 20 h to obtain NH 4 -SSZ-13.

[0046] (1-2) The preparation method of Pd-SSZ-13 (impregnation met...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com