Tool for machining motor shell

A technology for motor casings and machine tools, which is applied in the direction of electromechanical devices, manufacturing motor generators, electrical components, etc., and can solve problems such as low positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] The following is attached Figure 1-9The application is described in further detail.

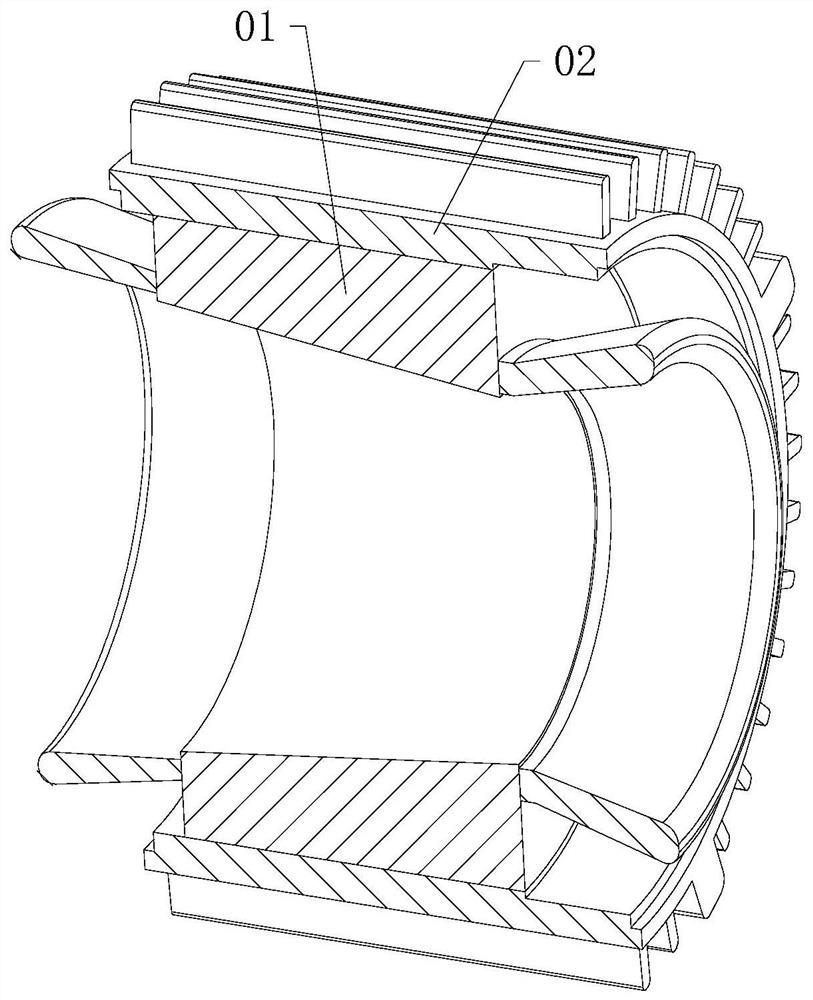

[0065] The conical rotor motor is mainly composed of a shell, a stator, a rotor, a machine cover and other accessories, and the inner hole of the stator and the outer circumference of the rotor are conical. Among them, refer to figure 1 , the stator 01 is pressed into the housing 02 by means of interference fit to form a product.

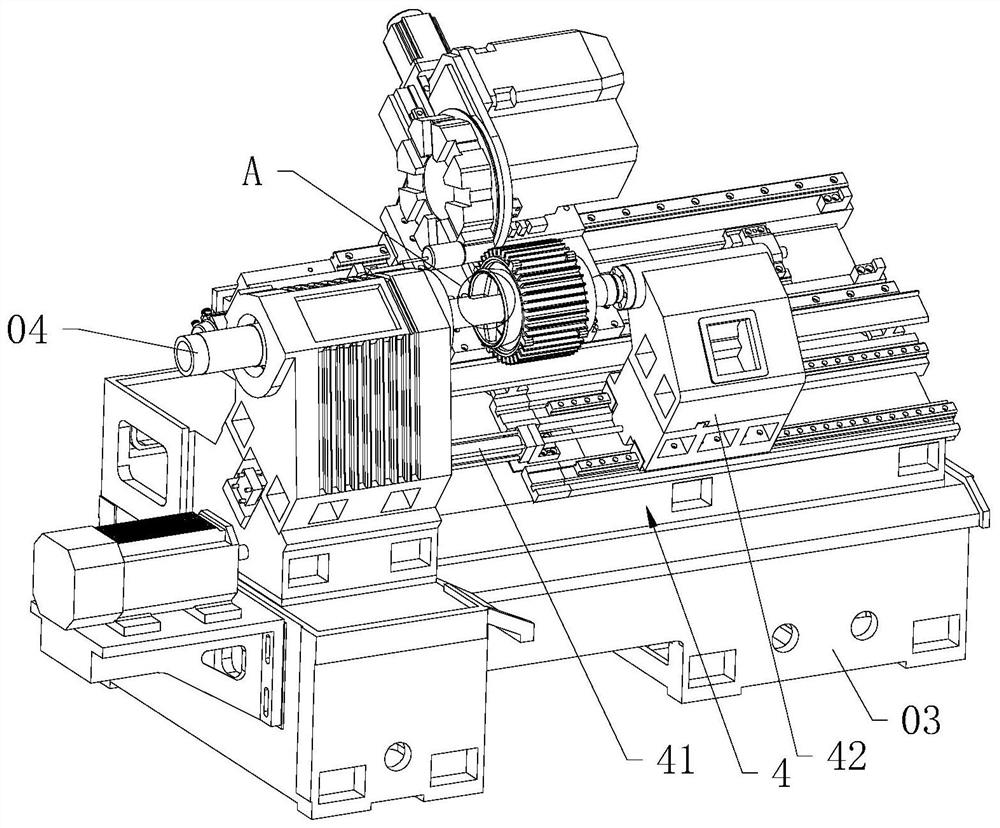

[0066] refer to figure 2 , the CNC machine tool includes a bed 03 and a spindle 04, one end of the spindle 04 is used to connect the motor, and the power transmission between the spindle 04 and the motor can be realized by belt transmission.

[0067] The embodiment of the present application discloses a tool for machining a motor casing.

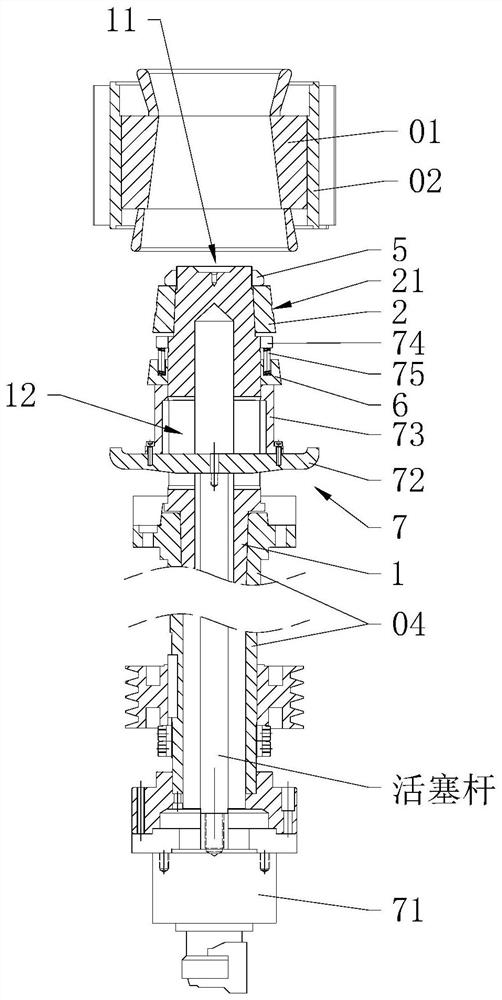

[0068] refer to image 3 , 4 , The tooling for machining the motor shell includes a base shaft 1 , a fixed cone ring 2 , a pressure plate 3 and a clamping driver 4 .

[0069] refer to image 3 , 5 , the base sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com