Method for determining content of effective extraction agent in three phases of copper extraction process

An extractant and three-phase technology, applied in the field of analysis and testing, can solve the problems of unsuitable determination of effective extractant content, hindering the interaction between the organic phase and the water phase, and slowing down the phase separation speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

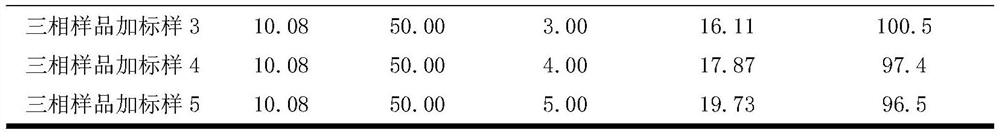

Examples

specific Embodiment approach

[0017] A method for measuring the effective extractant content in the copper extraction process three-phase:

[0018] 1. Weighing samples

[0019] Weigh 50-100g (accurate to 0.01g) of the fully mixed three-phase sample into a glass sand core funnel.

[0020] 2. Phase separation

[0021] Place the glass sand core funnel with the sample on the pre-washed and dried vacuum filter bottle, and filter with suction. After the filter residue is drained, wash it three times with extractant solvent, the amount of each time is the same as the sample amount, and filter until the filter residue is dry and cracked. In the separatory funnel, wash the suction filter flask once with the extraction agent solvent equal to the weighing amount, transfer the lotion to the separatory funnel together, let stand for 8 hours to separate the layers, and separate the water phase.

[0022] 3. Determination of the maximum copper loading capacity of the organic phase

[0023] 3.1 Preparation of copper st...

example 2

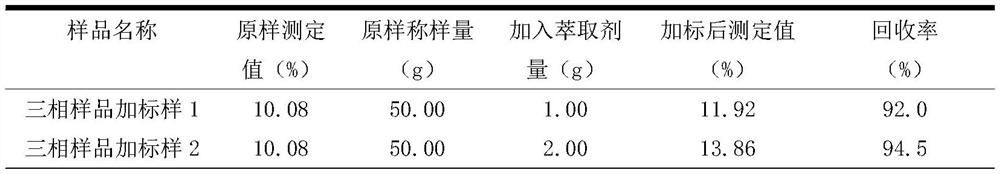

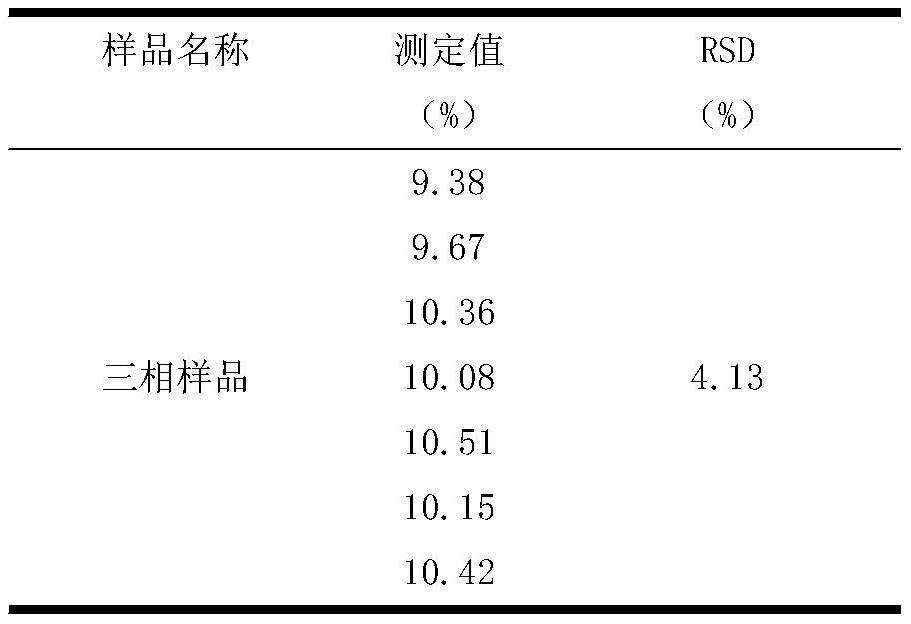

[0044] 5.2 Example 2: Sample determination precision:

[0045]

[0046] The results showed that the RSD was less than 5%, and the precision of the method met the daily detection requirements.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com