Full-automatic freeze-drying pharmaceutical equipment

A pharmaceutical equipment, fully automatic technology, used in drying solid materials, lighting and heating equipment, non-rotational vibration suppression, etc., can solve problems such as limiting the working range of the equipment, breaking the bottled medicine bottles, and difficult to move the equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

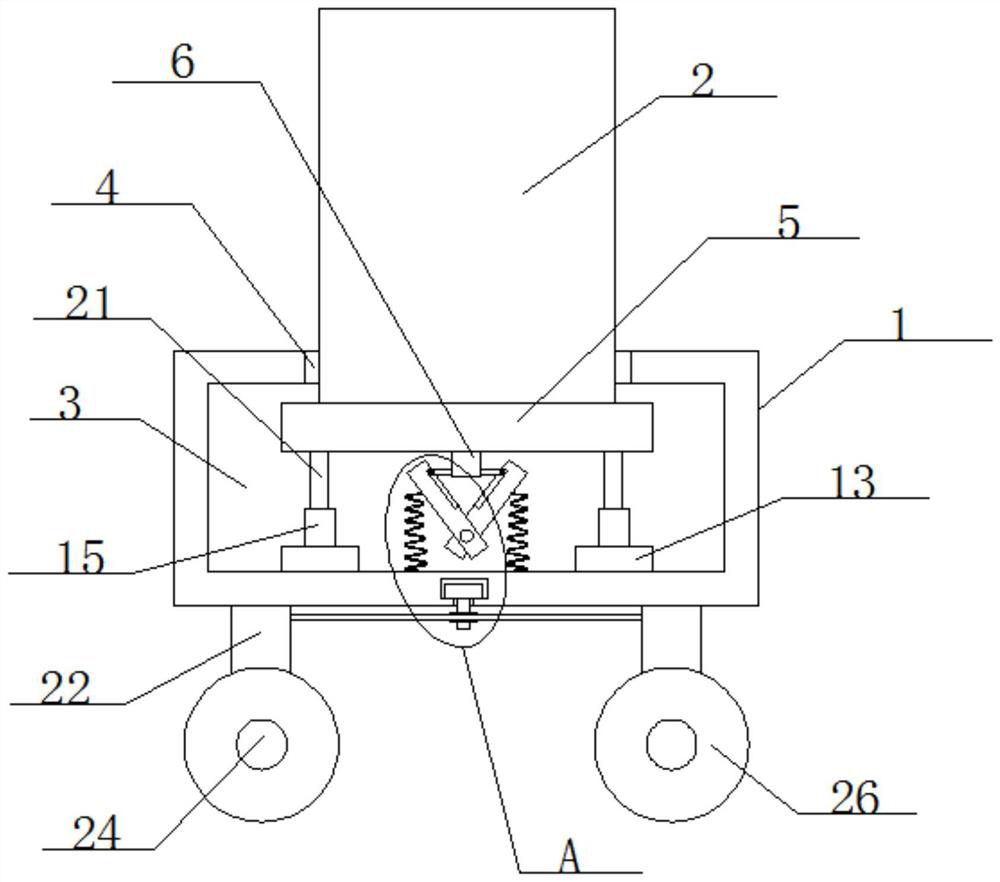

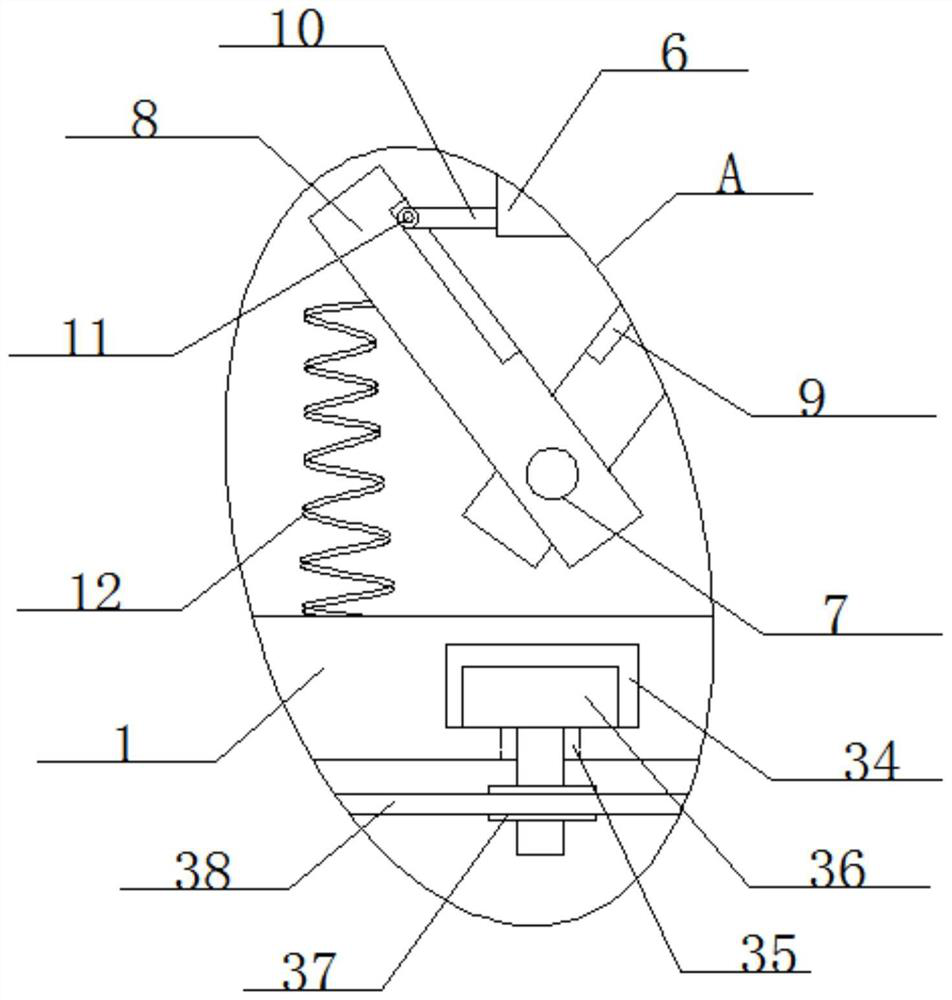

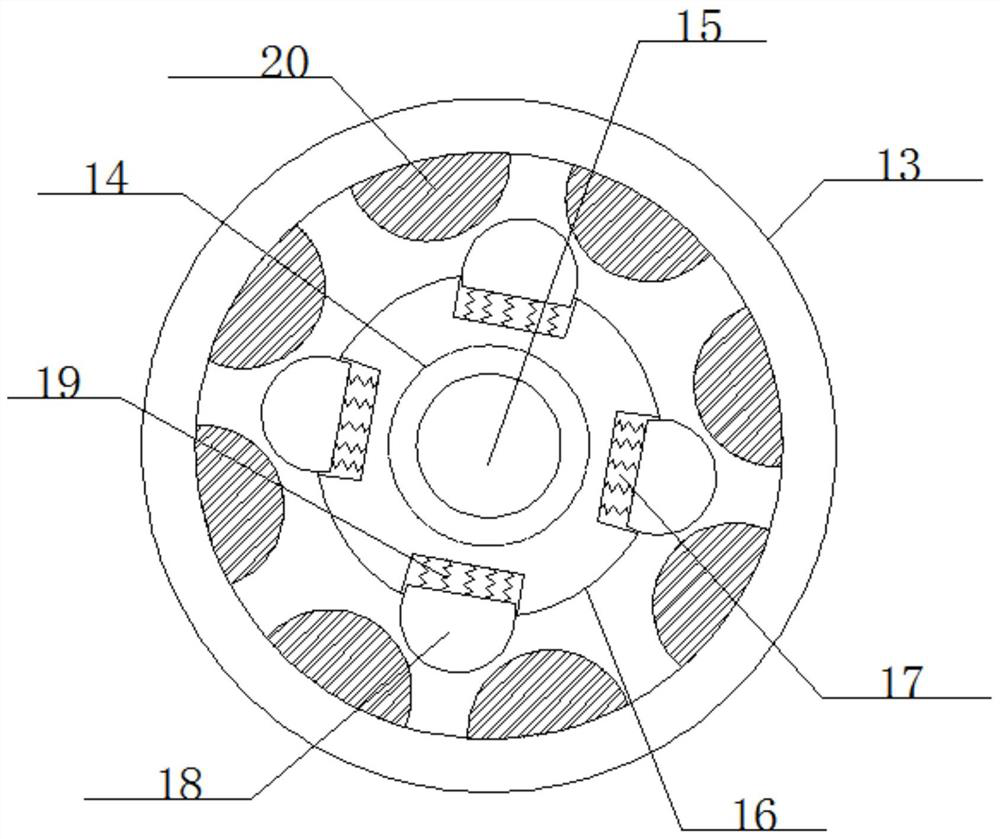

[0028] refer to Figure 1-6 , a fully automatic freeze-drying pharmaceutical equipment, comprising a shock-absorbing block 1 and a device body 2, a cavity 3 is opened inside the shock-absorbing block 1, and a vertical hole 4 is opened on the inner wall of the top of the cavity 3, and inside the cavity 3 A base 5 is provided, and the top side of the base 5 is fixedly installed on the device body 2, the center position of the bottom side of the base 5 is fixedly equipped with a moving block 6, and the inner wall on one side of the cavity 3 is rotatably equipped with a rotating rod 7, and the rotation Two oblique rods 8 are mounted on the rod 7 for cross rotation respectively, and the side of the two oblique rods 8 close to the moving block 6 is provided with a wheel groove 9, and both sides of the moving block 6 are fixedly equipped with straight rods 10, and the cavity 3 Two disks 13 are respectively fixedly installed on the inner wall of the bottom, and the inside of the disk ...

Embodiment 2

[0037] refer to Figure 1-6 , a fully automatic freeze-drying pharmaceutical equipment, comprising a shock-absorbing block 1 and a device body 2, a cavity 3 is opened inside the shock-absorbing block 1, and a vertical hole 4 is opened on the inner wall of the top of the cavity 3, and inside the cavity 3 A base 5 is provided, and the top side of the base 5 is fixedly installed on the device body 2, the center position of the bottom side of the base 5 is fixedly equipped with a moving block 6, and the inner wall on one side of the cavity 3 is rotatably equipped with a rotating rod 7, and the rotation Two oblique rods 8 are mounted on the rod 7 for cross rotation respectively, and the side of the two oblique rods 8 close to the moving block 6 is provided with a wheel groove 9, and both sides of the moving block 6 are fixedly equipped with straight rods 10, and the cavity 3 Two disks 13 are respectively fixedly installed on the inner wall of the bottom, and the inside of the disk ...

Embodiment 3

[0046] refer to Figure 1-6 , a fully automatic freeze-drying pharmaceutical equipment, comprising a shock-absorbing block 1 and a device body 2, a cavity 3 is opened inside the shock-absorbing block 1, and a vertical hole 4 is opened on the inner wall of the top of the cavity 3, and inside the cavity 3 A base 5 is provided, and the top side of the base 5 is fixedly installed on the device body 2, the center position of the bottom side of the base 5 is fixedly equipped with a moving block 6, and the inner wall on one side of the cavity 3 is rotatably equipped with a rotating rod 7, and the rotation Two oblique rods 8 are mounted on the rod 7 for cross rotation respectively, and the side of the two oblique rods 8 close to the moving block 6 is provided with a wheel groove 9, and both sides of the moving block 6 are fixedly equipped with straight rods 10, and the cavity 3 Two disks 13 are respectively fixedly installed on the inner wall of the bottom, and the inside of the disk ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com