Flange nut for building support

A technology of using flange screws and construction, applied in the direction of nuts, screws, bolts, etc., can solve the problems of poor anti-loosening performance of flange nuts, losses, casualties and property, etc., and achieve reasonable design, simple structure, and improved anti-loosening performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

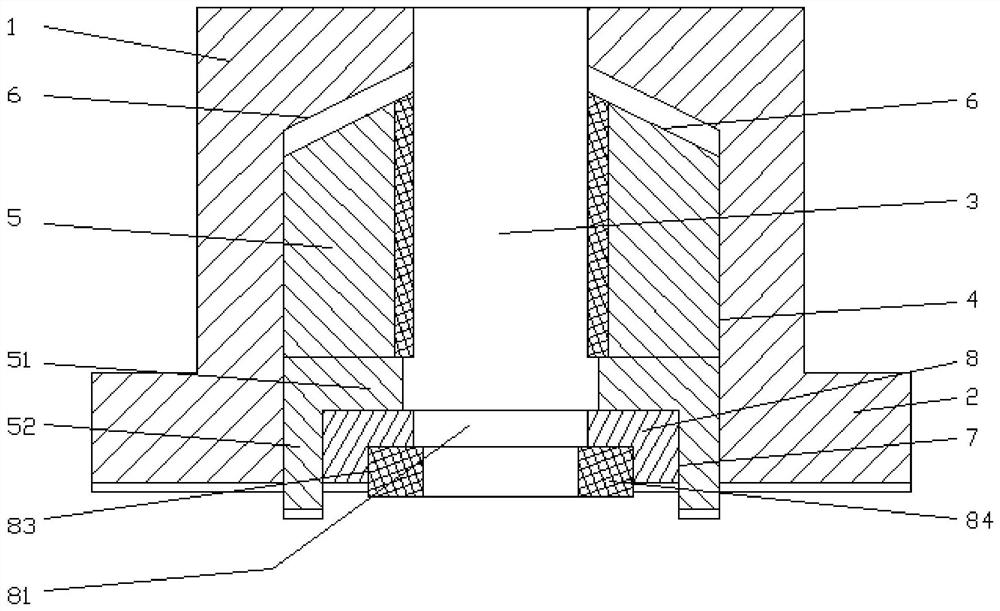

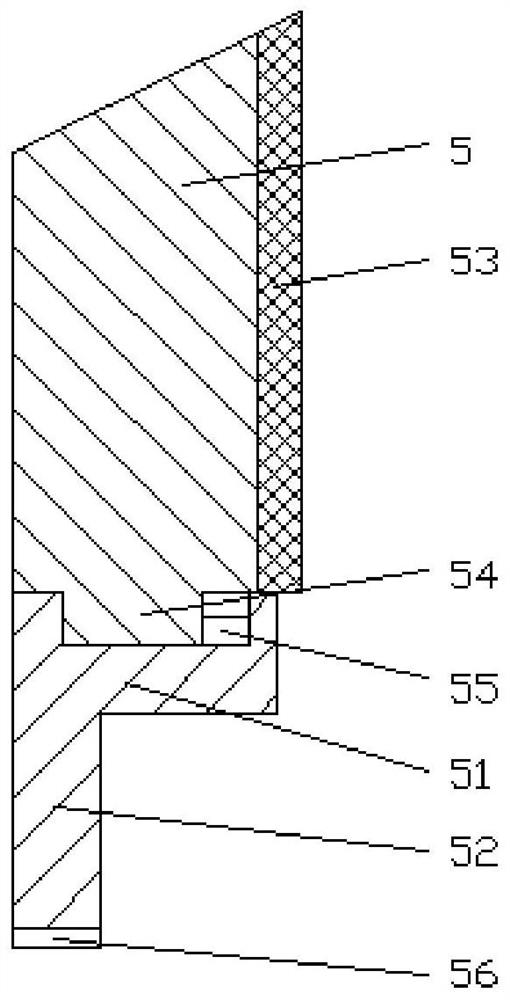

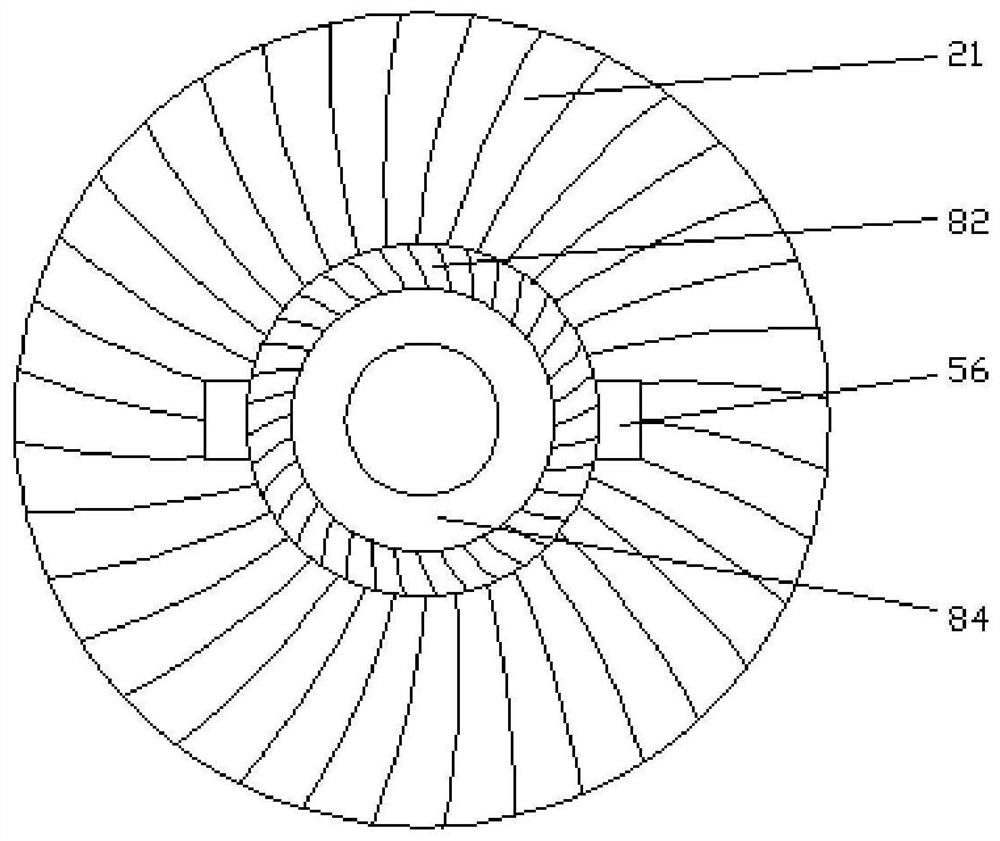

[0018] Referring to the accompanying drawings, a flange nut for a building support of the present invention includes a nut body 1, a flange plate 2, a threaded through hole 3, a clamping block installation groove 4, a clamping block 5, an inclined surface 6, a locking groove 7 and a limiter. Bit plate 8, the bottom of the nut body 1 is provided with a flange 2, the flange 2 and the nut body 1 are integrally designed, the inside of the nut body 1 is provided with a threaded through hole 3, and the threaded through hole 3 The hole 3 vertically runs through the nut body 1 and the flange 2, and the inside of the threaded through hole 3 is provided with a number of clamping block installation grooves 4, and the inside of the clamping block installation groove 4 is provided with a clamping block 5. The tops of the block mounting groove 4 and the clamping block 5 are provided with an upwardly inclined slope 6, the clamping block mounting groove 4 extends downward and is flush with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com