An anti-loosening anti-vibration screw assembly

A technology of screw components and loose parts, applied in the direction of screws, threaded fasteners, bolts, etc., can solve problems such as loosening or even separation of structural parts, casualties, equipment damage, etc., to achieve anti-loosening effect, reduce impact, reduce Possible effects of autoloosening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

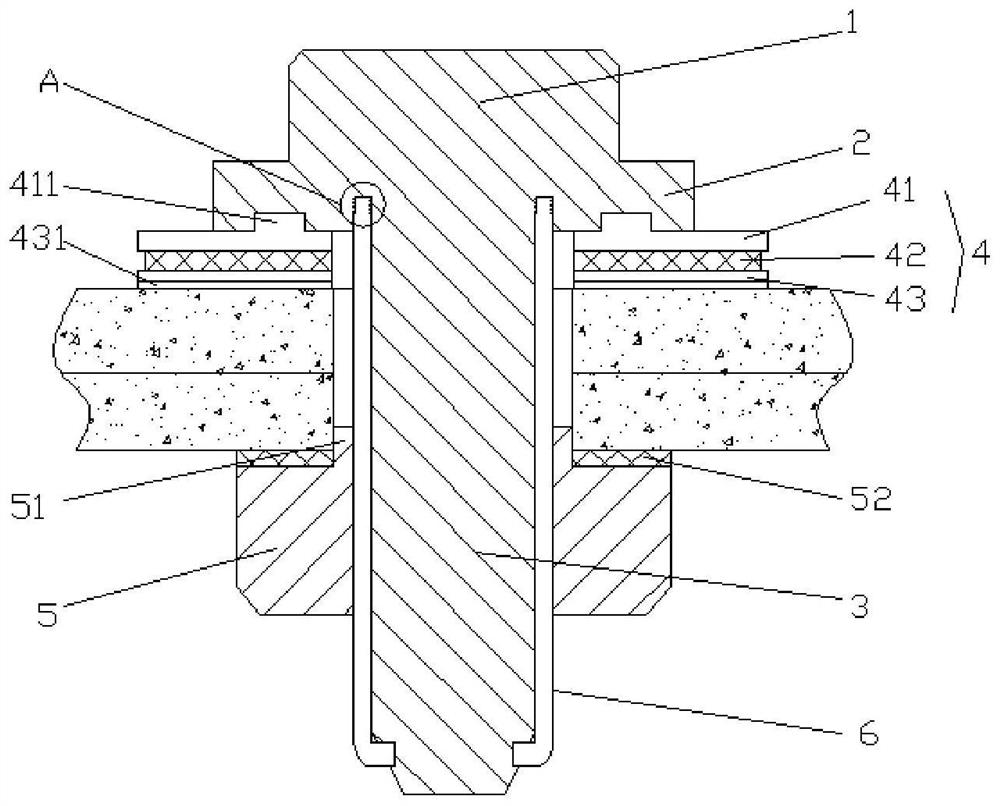

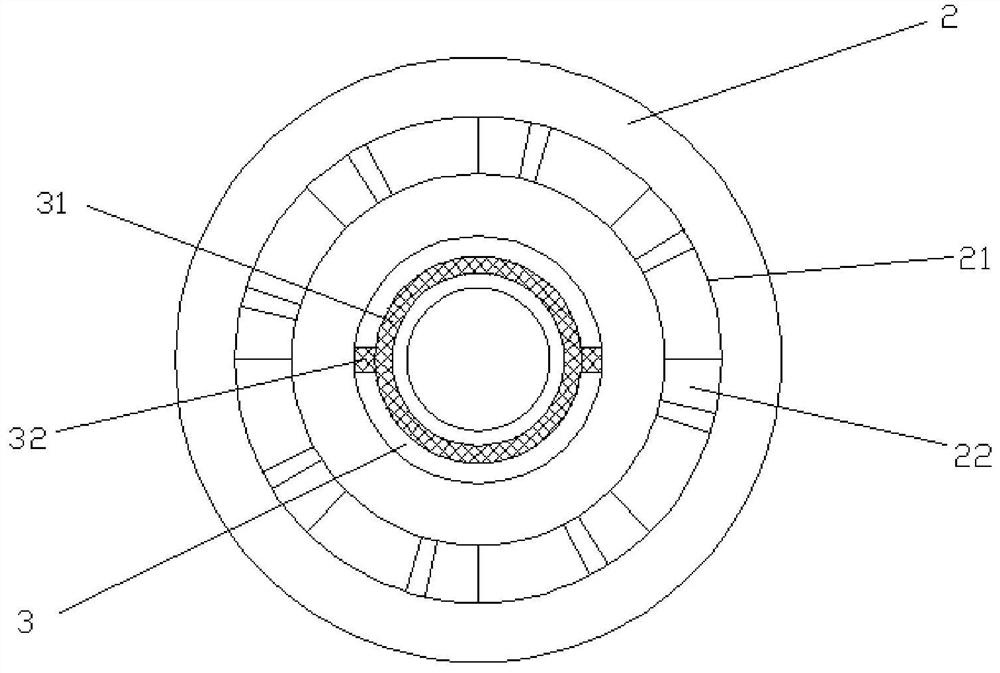

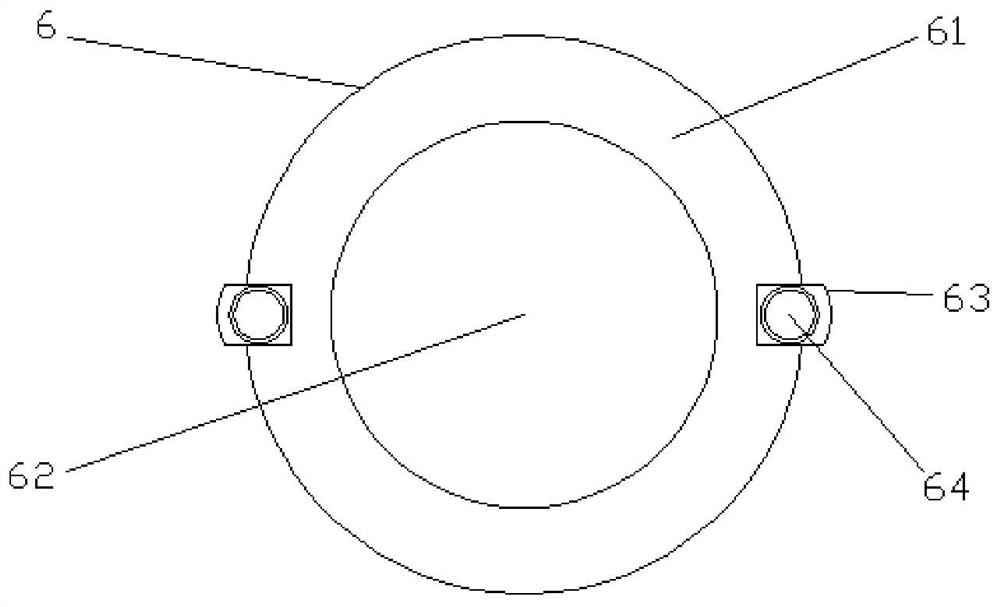

[0018] Referring to the accompanying drawings, an anti-loosening and anti-vibration screw assembly of the present invention includes a screw head 1, a transition section 2, a stud 3, an anti-loosening and anti-vibration gasket 4, a nut 5 and a nut anti-loosening part 6, and the screw head 1 The bottom of the transition section 2 is provided with a transition section 2, and the bottom of the transition section 2 is provided with a stud 3, and the stud 3 is provided with a nut anti-loosening part 6, and the nut anti-loosening part 6 and the outer side of the stud 3 are provided with anti-loosening parts. Loosen the anti-vibration gasket 4 and the nut 5, and the anti-loosening anti-vibration gasket 4 is located between the transition section 2 and the nut 5.

[0019] Wherein, the bottom of the transition section 2 is provided with a buckle groove 21, and the buckle groove 21 is provided with buckle teeth 22 distributed in a circular shape, and a group of connecting grooves 23 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com