A lint cleaning device for fabric production

A cleaning device and lint technology, applied in thin material processing, textile material cutting, mechanical cleaning, etc., can solve troublesome and laborious problems, and achieve convenient and effective finishing of fabrics, prevention of fabric wrinkles, and convenient and effective collection of fabrics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

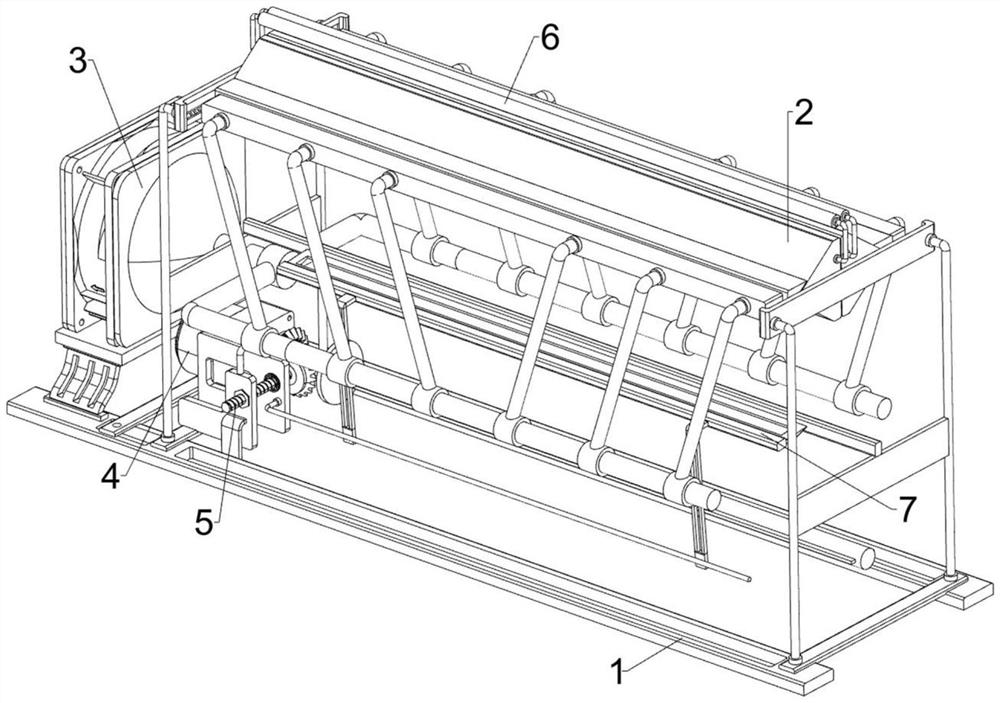

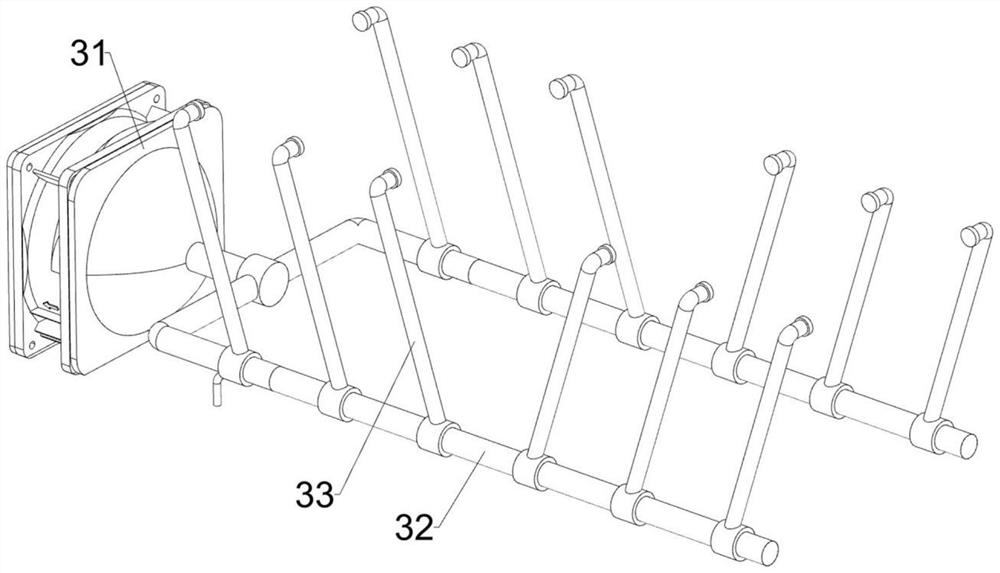

[0025] A lint cleaning device for cloth production, such as Figure 1-4 As shown, it includes a bracket 1, a fixed component 2, a dust suction component 3, a winding component 4 and a moving component 5. The upper side of the bracket 1 is equipped with a fixed component 2, and the upper middle of the bracket 1 is equipped with a dust suction component 3. The bracket The lower side of 1 is installed with winding assembly 4, and the front side of support 1 is installed with moving assembly 5.

[0026] When it is necessary to clean the lint of the cloth, the cloth is wound on the winding assembly 4 through the fixed assembly 2, and the dust suction assembly 3 is controlled to start, the dust suction assembly 3 will clean the lint on the cloth, and then the winding assembly 4 is started , the winding component 4 winds the cloth, and pulls the cloth to pull off the cleaned cloth. At the same time, the winding component 4 will also drive the moving component 5 to operate, thereby co...

Embodiment 2

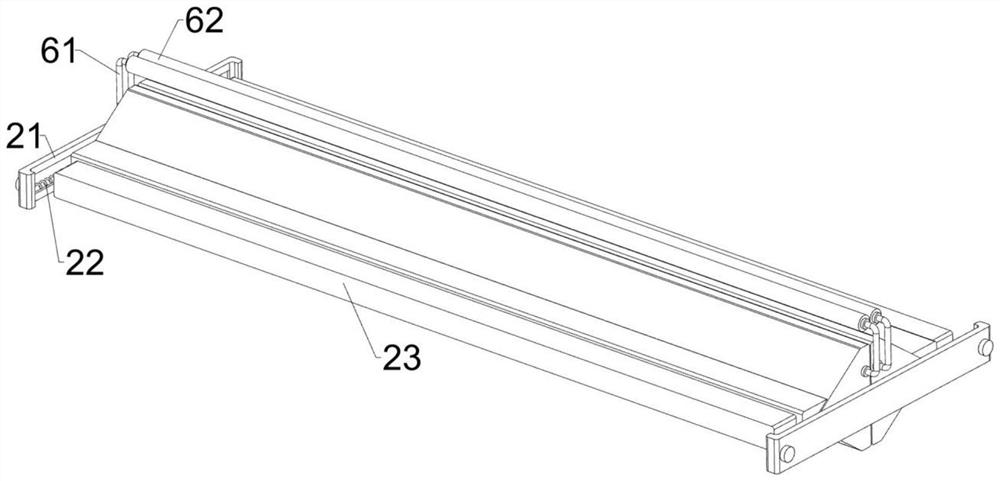

[0036] On the basis of Example 1, such as figure 1 , figure 2 and Figure 5As shown, also include straightening assembly 6, and straightening assembly 6 includes concave rod 61 and cylinder 62, and the left and right two parts of front and rear sides suction cover 23 are all connected with concave shape rod 61, and front and back both sides dust suction cover 23 is connected with a cylinder 62 between the left and right concave rods 61 upper ends, and the cylinders 62 cooperate with each other.

[0037] When it is necessary to clean the lint of the cloth, the dust collection cover 23 is pulled open, and the dust collection cover 23 drives the roller 62 to be pulled together, and the cloth is put into the dust collection cover 23 through the roller 62. When the device is in operation, the roller 62 can be straightened. Cloth, prevents cloth wrinkle, makes cloth cleaning cleaner, and roller 62 can also make cloth vertically enter in the dust collection cover 23, thereby reduc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com