Extraction method of Chinese wolfberry polysaccharide, Chinese wolfberry polysaccharide tablet and preparation method thereof

A technology of Lycium barbarum polysaccharide and extraction method, which is applied in food extraction, polysaccharide/gum-containing food ingredients, food processing and other directions, can solve the problems of complex composition, low purity, low extraction rate, etc., to reduce the generation of pollutants and achieve high efficiency , the method is simple and feasible effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

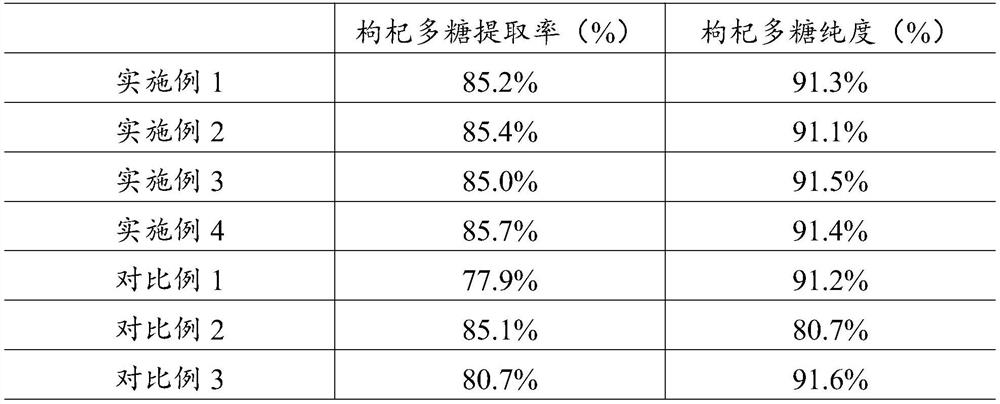

Examples

preparation example Construction

[0045] The present invention also provides a kind of preparation method of polysaccharide tablet, comprises the following steps:

[0046] (I) crushing and sieving Lycium barbarum polysaccharide to obtain Lycium barbarum polysaccharide powder;

[0047] (II) After mixing Lycium barbarum polysaccharide with starch, lactose and sodium carboxymethyl cellulose, a mixed raw material is obtained;

[0048] (Ⅲ) mixing the mixed raw materials with an aqueous ethanol solution to obtain the soft material of Lycium barbarum polysaccharide tablets;

[0049] (Ⅳ) After the soft material of Lycium barbarum polysaccharide tablets is granulated to 18 meshes, wet granules are obtained;

[0050] (Ⅴ) Drying the wet granules in sequence, and sieving the whole granules to obtain dry granules;

[0051] (VI) Mix and compress the dry granules with magnesium stearate to obtain Lycium barbarum polysaccharide tablets.

[0052] The invention grinds and sieves the wolfberry polysaccharide to obtain the wol...

Embodiment 1

[0060] Lycium barbarum polysaccharide extraction:

[0061] (1) Mix 1kg of dried wolfberry and 10L of water, extract at 100°C for 1 hour, and filter to obtain 8.5L of the first extract and the filter residue of the first extract;

[0062] (2) Mix the filter residue of the above-mentioned first extract with 8L of water, extract at 100°C for 1 hour, filter, and perform heating extraction to obtain 8.3L of the second extract and the filter residue of the second extract;

[0063] (3) Mix the above-mentioned 8.5L first extract with 8.3L second extract, filter the extract with a filter paper plate with a pore size of 1 μm, remove suspended particles to obtain a clarified filtrate, add 0.02% enzyme of the extract quality to the filtrate, wherein The mass ratio of neutral protease and papain is 1:3, and the enzyme activity of the neutral protease is 50000U / g; the enzyme activity of the papain is 100000U / g; the enzymolysis is obtained by stirring at 42°C for 12 hours. Extraction soluti...

Embodiment 2

[0076] Lycium barbarum polysaccharide extraction:

[0077] (1) Mix 10kg wolfberry and 100L water, extract at 100°C for 1 hour, and filter to obtain 86L of the first extract and the filter residue of the first extract;

[0078] (2) Mix the filter residue of the above-mentioned first extract with 80 L of water, extract at 100° C. for 1 hour, filter, and perform heating extraction to obtain 85 L of the second extract and the filter residue of the second extract;

[0079] (3) Mix the above-mentioned 86L first extract with 85L second extract, filter the extract with a filter paper plate with a pore size of 1 μm, remove suspended particles to obtain a clarified filtrate, add 0.02% enzyme of the extract quality to the filtrate, wherein neutral The mass ratio of protease and papain is 1:3, the enzyme activity of the neutral protease is 50000U / g; the enzyme activity of the papain is 100000U / g; the enzymolysis solution is obtained by stirring at 42°C for 12 hours ;

[0080] (4) The ab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesh | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com