Segmented prefabrication method of immersed tube joints

A technology of pipe joints and immersed pipes, which is applied to manufacturing tools, artificial islands, underwater structures, etc., can solve the problems of high crack control difficulty, long prefabrication cycle, and large prefabricated factory area, so as to improve project quality and low cost. , the effect of shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

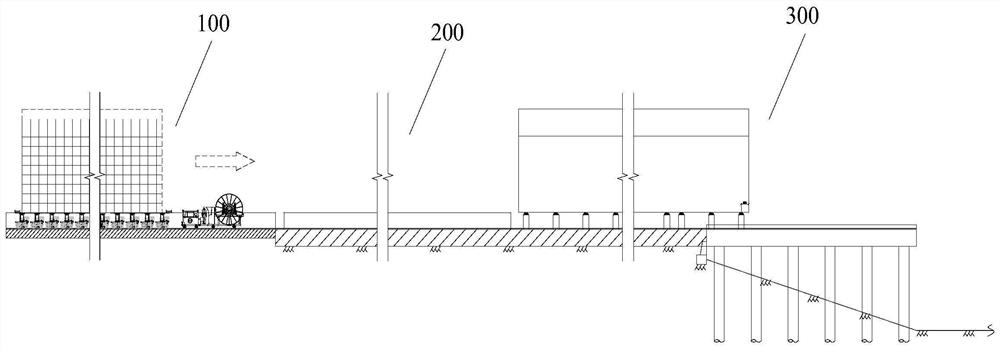

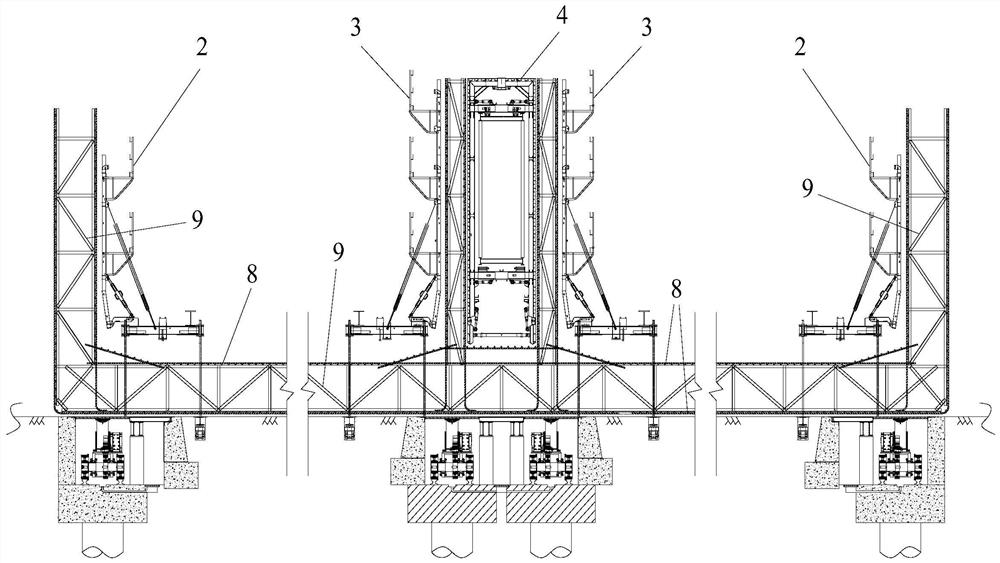

[0046] For example, the section of the immersed tunnel adopts the scheme of two holes and one pipe gallery, the main line of the standard road section adopts two-way 8 lanes, the total length of the tunnel is 2310m, and it is divided into 29 pipe sections (80m×28 sections+70m×1 section), and the width of the immersed pipe section is 42.8 m, height 10.9m, 1.5m thick pipe joint structure top and bottom plate, 1.4m thick side wall, 0.7m thick middle partition wall, 2m wide middle corridor, and 161.8m structural sectional area 2 , the length of a single pipe joint is 80m, which can be divided into 3 sections to be poured, and each section to be poured is about 26.7m long.

[0047] The segmental prefabrication method of an immersed tube section according to the present invention for a single pipe section includes the following steps:

[0048] a. Bind the bottom plate steel bars, outer wall steel bars and middle wall steel bars of the entire pipe joint in the steel bar binding area ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com