Solar photovoltaic panel cleaning device and cleaning method for industrial production

A technology for solar photovoltaic panels and cleaning devices, which is applied in the direction of cleaning methods, cleaning methods and utensils using tools, photovoltaic power generation, etc., can solve the problems of inconvenient adjustment of solar photovoltaic panels, etc. Effects of the use of the drive structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

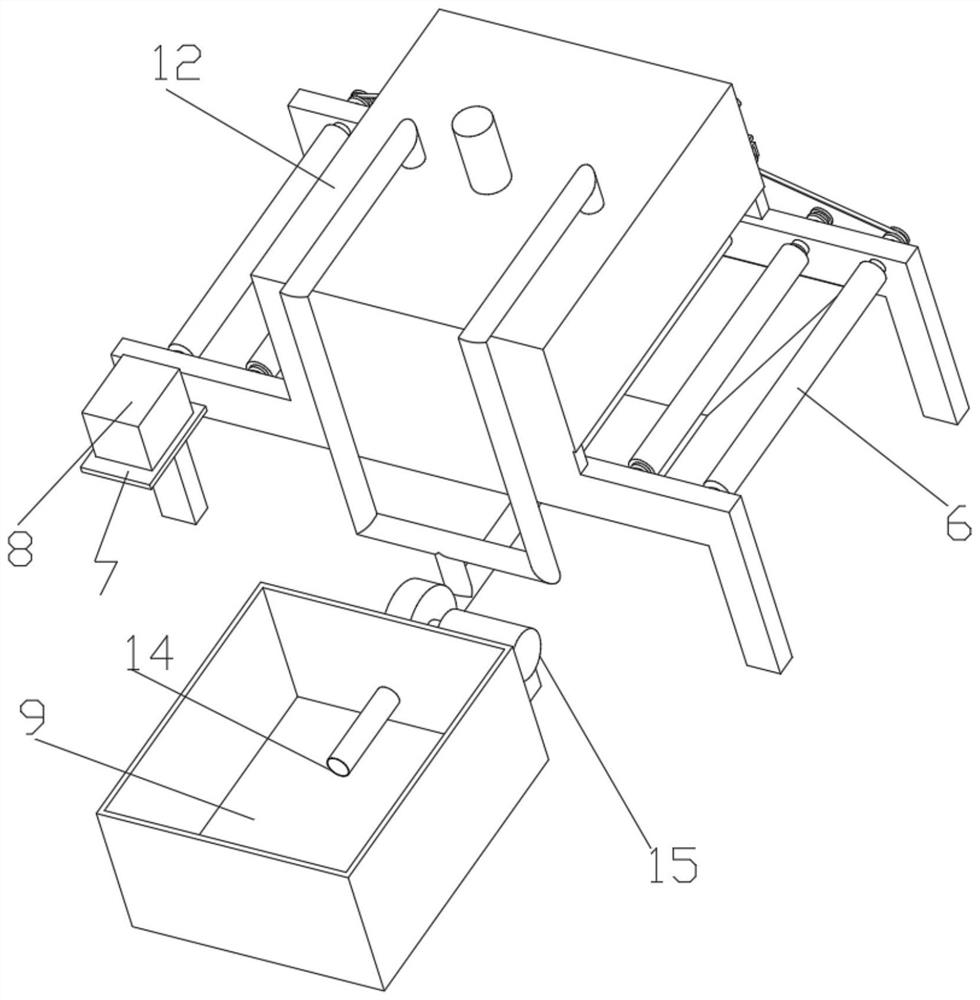

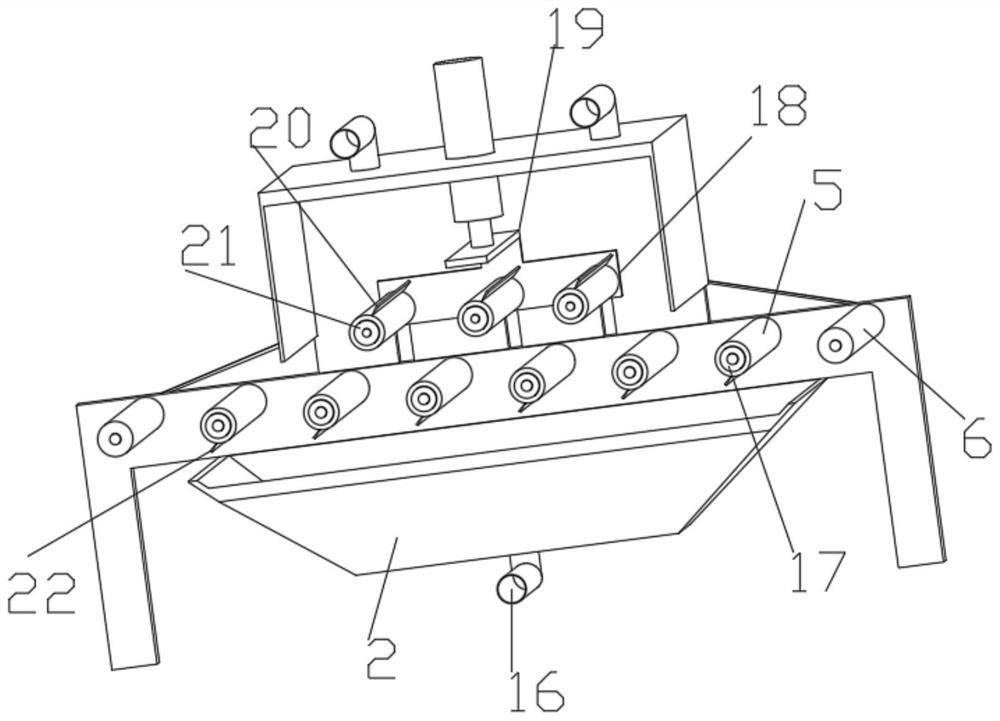

[0034] A solar photovoltaic panel cleaning device for industrial production in this embodiment includes a support plate 1, a drive motor 8, an electric push rod 10 and an air pump 15, and the left and right ends of the support plate 1 are rotatably connected with support rollers 6 through fixedly connected bearings , the support roller 6 is fixedly connected to the output end of the drive motor 8, the outer wall of the support plate 1 is fixedly connected with the support plate 7, the top of the support plate 7 is fixedly connected with the drive motor 8, and the support plate 1 is fixedly connected between the support rollers 6 The bearing shaft of the bearing is connected with the lower rotating roller 17, the bottom of the support plate 1 is fixedly connected with the lower air suction cover 2, and the bottom of the lower air suction cover 2 is fixedly connected with the lower air outlet pipe 16, and the lower air outlet pipe 16 is fixed to the input end of the air pump 15. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com