Ruthenium-based catalyst and preparation method and application thereof

A ruthenium-based catalyst and a ruthenium-based dichalcogenide technology, applied in the field of electrochemical catalysis, can solve problems such as high cost and poor acid resistance, and achieve the effects of high production efficiency, reduced production cost and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

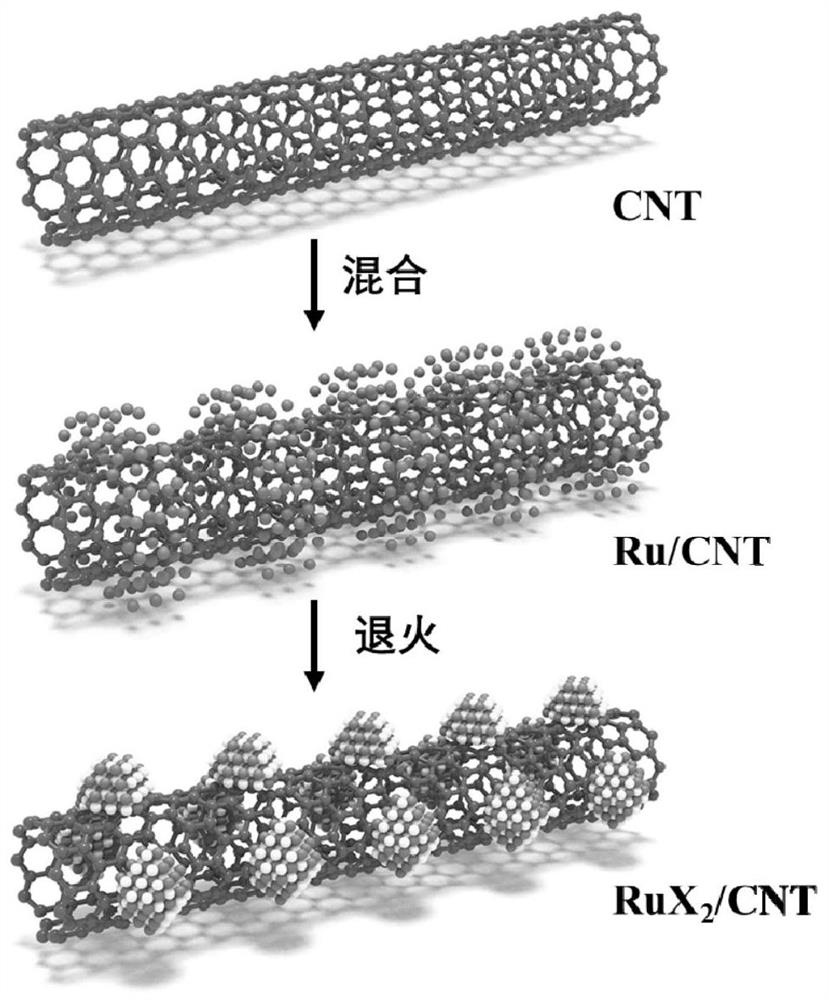

[0031] Correspondingly, the embodiment of the present invention also provides a preparation method of a ruthenium-based catalyst, which includes the following steps:

[0032] S1. Provide carbon support, ruthenium source and precursors containing chalcogen elements;

[0033] S2. Mixing and annealing the carbon support, ruthenium source, and chalcogen-containing precursor to obtain a ruthenium-based catalyst.

[0034] The preparation method of the ruthenium-based catalyst provided by the embodiment of the present invention is to make the obtained ruthenium-based catalyst have higher catalytic activity and be in acidic solution and Both exhibited excellent electrochemical hydrogen evolution performance in alkaline solution systems. In addition, the preparation method of the ruthenium-based catalyst provided by the invention has controllable process conditions, good repeatability, high production efficiency, and effectively reduces production costs.

[0035]Specifically, in S1, ...

Embodiment 1

[0049] The present embodiment provides a kind of preparation method of ruthenium-based catalyst, comprises the following steps:

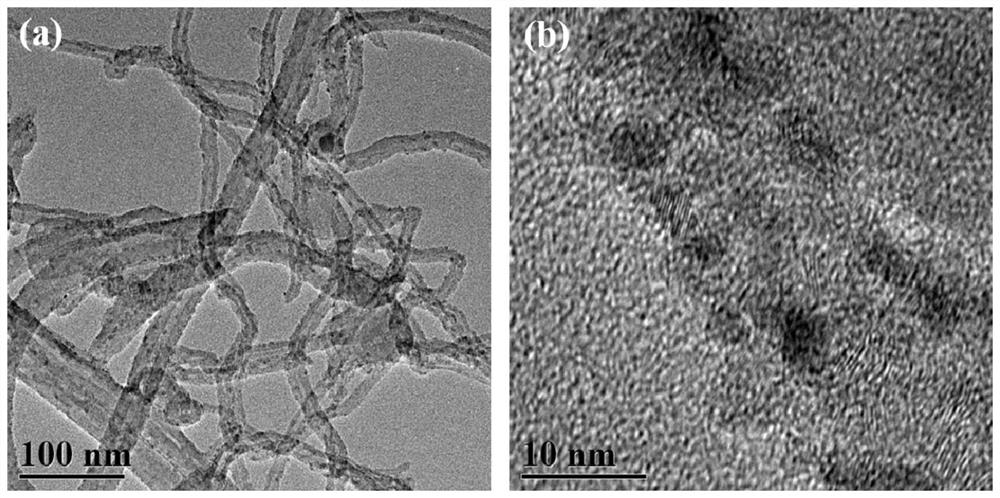

[0050] (11) Dissolve 1 g of carbon nanotubes (CNT) in 100 ml of concentrated nitric acid, stir for 1 h, ultrasonicate for 0.5 h, then place in an oil bath and heat to 100°C for reflux treatment, keep for 4 h, and cool down naturally. Use deionized water to carry out centrifugal washing, and then dry at 50°C for 10 hours under vacuum conditions to obtain oxidized carbon nanotubes;

[0051] (12) Add 100 mg of oxidized carbon nanotubes into 50 ml of deionized water, stir for 0.5 h, and sonicate for 1 h to disperse evenly. Add 30mg of ruthenium chloride, stir for 0.5h, sonicate for 1h, then freeze it quickly with liquid nitrogen, and dry it in a freeze dryer for 10h;

[0052] (13) put into the quartz boat after the mixture of carbon nanotube and ruthenium chloride is ground, place the central position of tube furnace, place the quartz boat that 200mg / L...

Embodiment 2

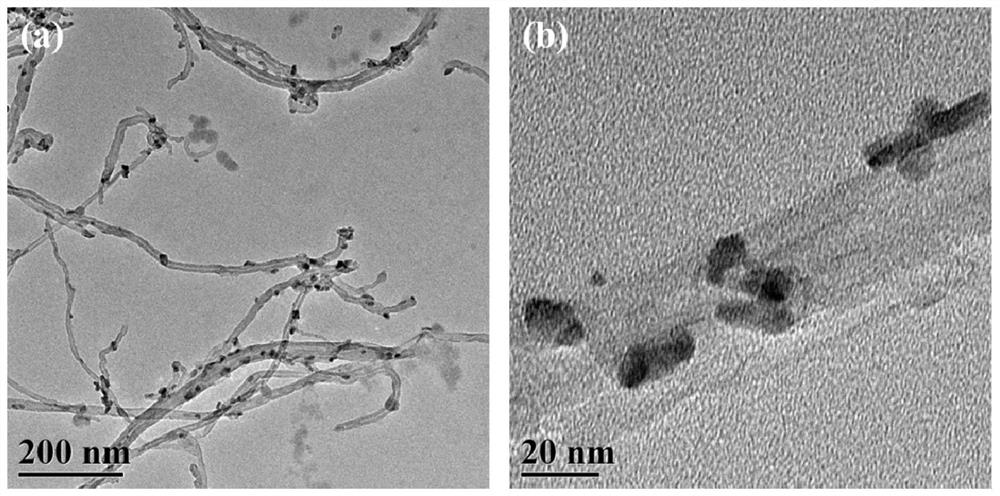

[0054] The present embodiment provides a kind of preparation method of ruthenium-based catalyst, comprises the following steps:

[0055] (21) Dissolve 1 g of carbon nanotubes (CNT) in 100 ml of concentrated nitric acid, stir for 1 h, ultrasonicate for 0.5 h, then place in an oil bath and heat to 100°C for reflux treatment, keep for 4 h, and cool down naturally. Use deionized water to carry out centrifugal washing, and then dry at 50°C for 10 hours under vacuum conditions to obtain oxidized carbon nanotubes;

[0056] (22) Add 100 mg of oxidized carbon nanotubes into 50 ml of deionized water, stir for 0.5 h, and sonicate for 1 h to disperse evenly. Add 30mg of ruthenium chloride, stir for 0.5h, sonicate for 1h, then freeze it quickly with liquid nitrogen, and dry it in a freeze dryer for 10h;

[0057] (23) put into the quartz boat after the mixture of carbon nanotube and ruthenium chloride is ground, place the central position of tubular furnace, place the quartz boat that 200m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com