Complete equipment and method for drum sulfur granulation with cooling flow channel

A complete set of equipment and cooling flow technology, applied in chemical instruments and methods, sulfur preparation/purification, granulation in rotary tanks, etc., can solve the problems of loss of cooling water, high consumption of public works, and large footprint. Achieve the effect of improving heat exchange efficiency, no equipment wear, and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

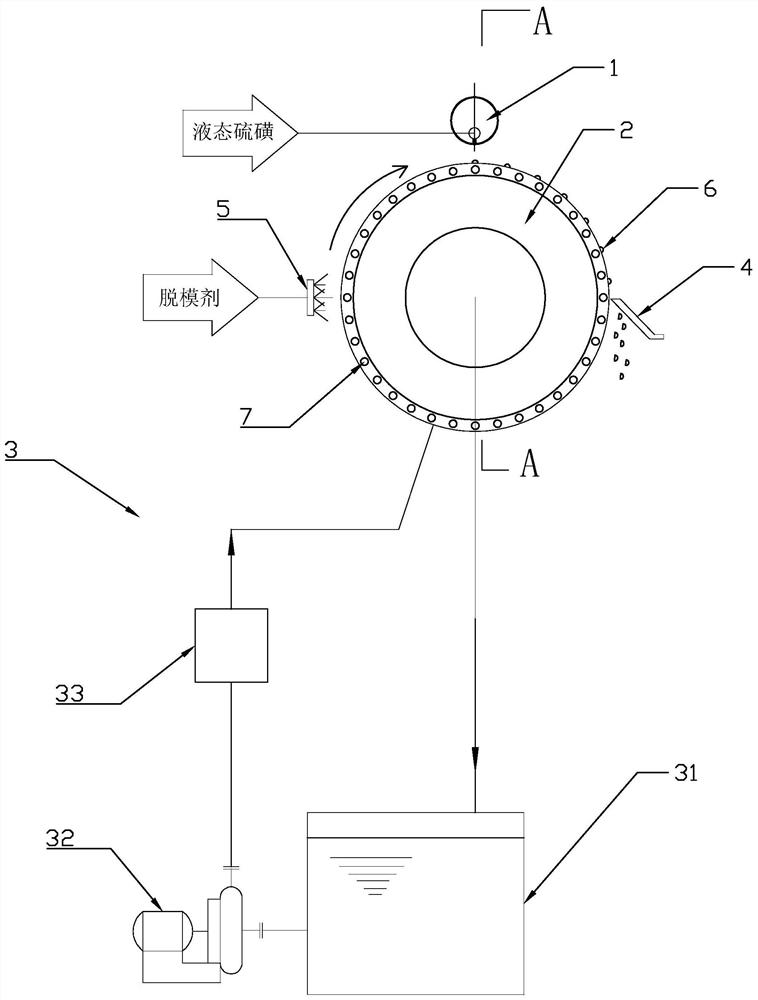

[0048] Such as figure 1 , figure 2 As shown, the present invention provides a complete set of drum sulfur granulation equipment with a cooling flow channel, including a liquid sulfur distributor 1, a cooling granulation drum 2, a cooling water circulation system 3, a scraper 4 and a release agent system 5;

[0049] The liquid sulfur distributor 1 can distribute and drop the liquid sulfur produced by the upstream device to the outer surface of the cooling granulation drum 2;

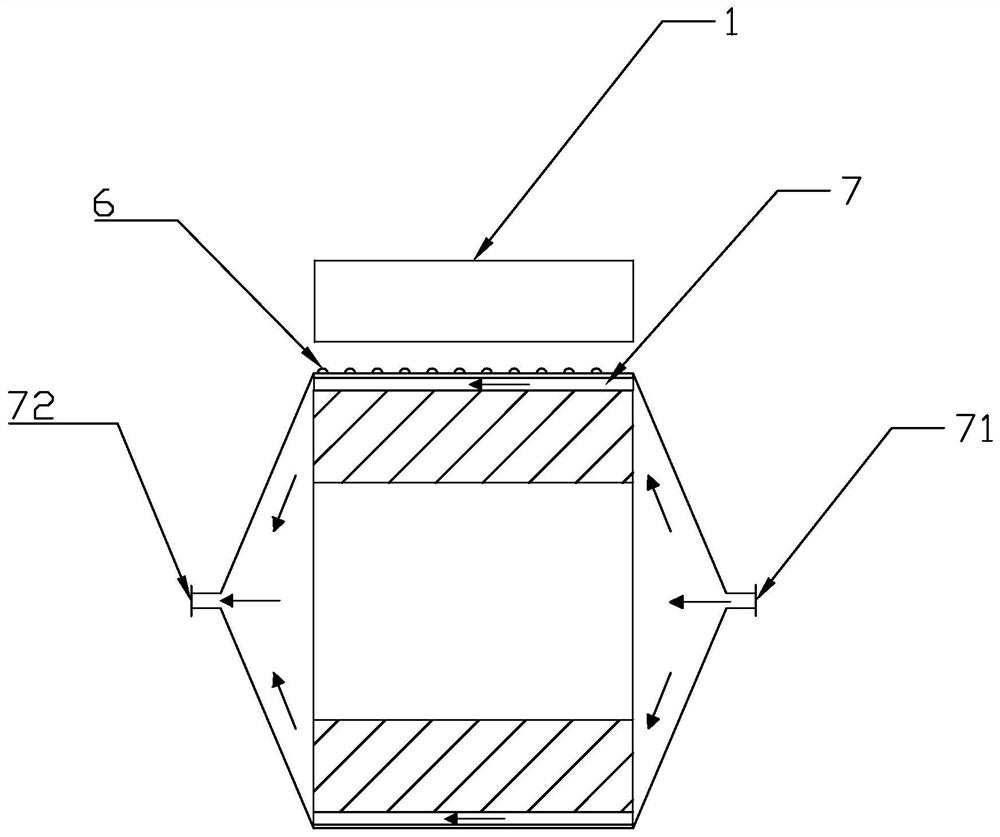

[0050] The cooling granulation drum 2 is horizontally arranged below the liquid sulfur distributor 1 and can rotate around the central axis, and its outer surface can be cooled by liquid sulfur to form hemispherical sulfur particles 6, which A cooling flow channel 7 is provided inside the wall thickness, which can quickly cool the outer surface; the cooling flow channel 7 has multiple and has a unified cooling water inlet 71 and a unified cooling water outlet 72;

[0051] The cooling water circulation ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com