Salt mist removal filtering system

A filtration system and salt spray technology, applied in the fields of dispersed particle filtration, dispersed particle separation, chemical instruments and methods, etc., can solve problems such as corrosion damage, shortened service life, and equipment performance degradation, and achieve good durability and shape retention. The effect of increasing the service life and reducing the chance of corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

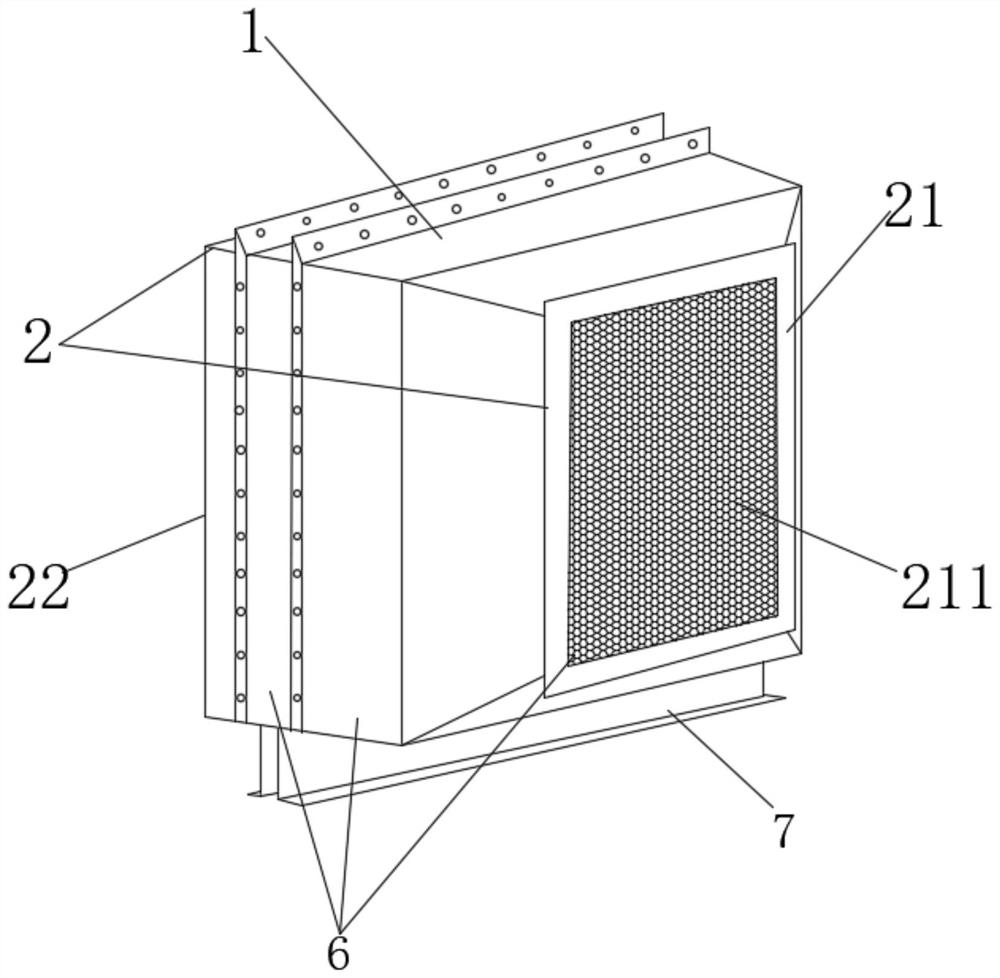

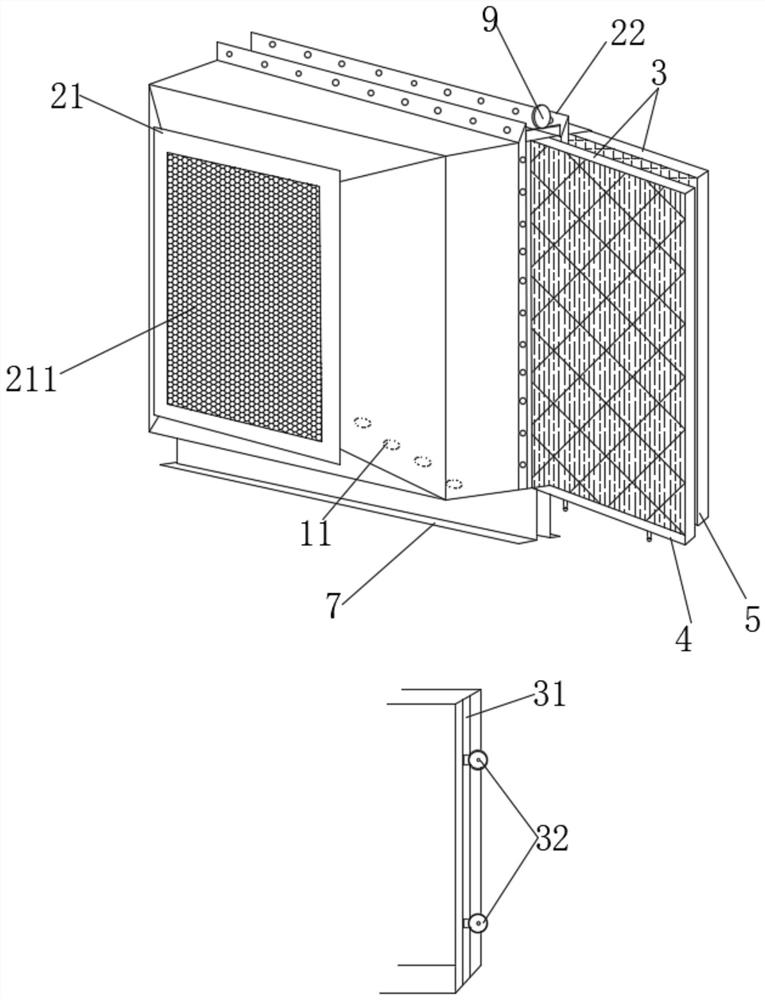

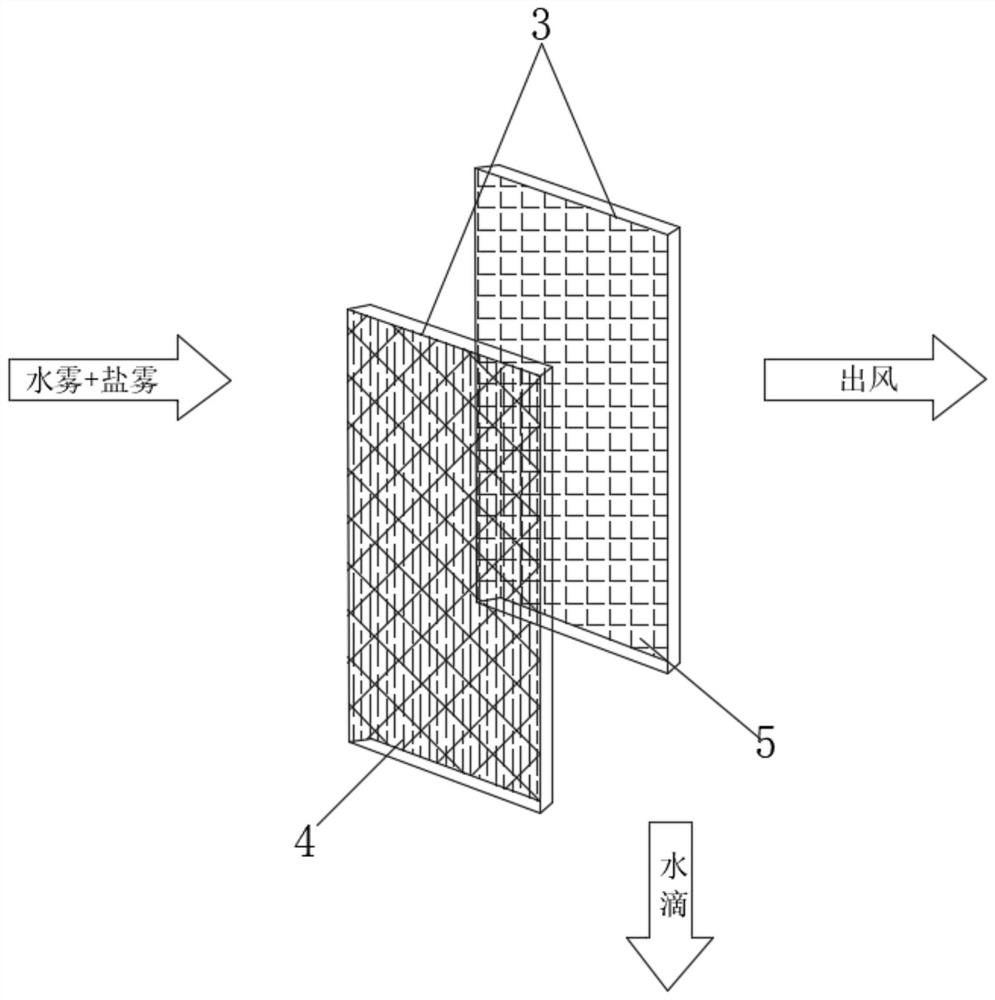

[0026] Example 1: please refer to figure 1 , figure 2 , Figure 4 and Figure 5 , a filter system for removing salt mist according to the present invention includes a system body box 1, the system body box 1 includes an outer frame 2 and a filter 3, and the outer frame 2 includes a top outer frame 21 and a bottom outer frame 22, so The filter 3 includes a first filter 4 and a second filter 5, the first filter 4 contains a first filter layer 41 and a second filter layer 42 inside, and the first filter layer 41 is vertically The vertical direction is above the second filter layer 42; the second filter 5 contains a chemical fiber layer 51 and a glass fiber layer 52;

[0027] Preferably, the first filter 4 is a metal mesh filter. A layer of high-strength stainless steel pleated mesh is provided on the air inlet and outlet surfaces of the metal mesh filter, and several layers of stainless steel mesh are woven inside. This design allows the airflow to pass through The metal mes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com