Automatic poultry feeding equipment

A technology for automatic feeding and equipment, applied in the poultry industry, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of high cooling costs, large investment costs, waste of water and power resources, etc., to reduce feed waste. efficiency, faster consumption, and lower cooling costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

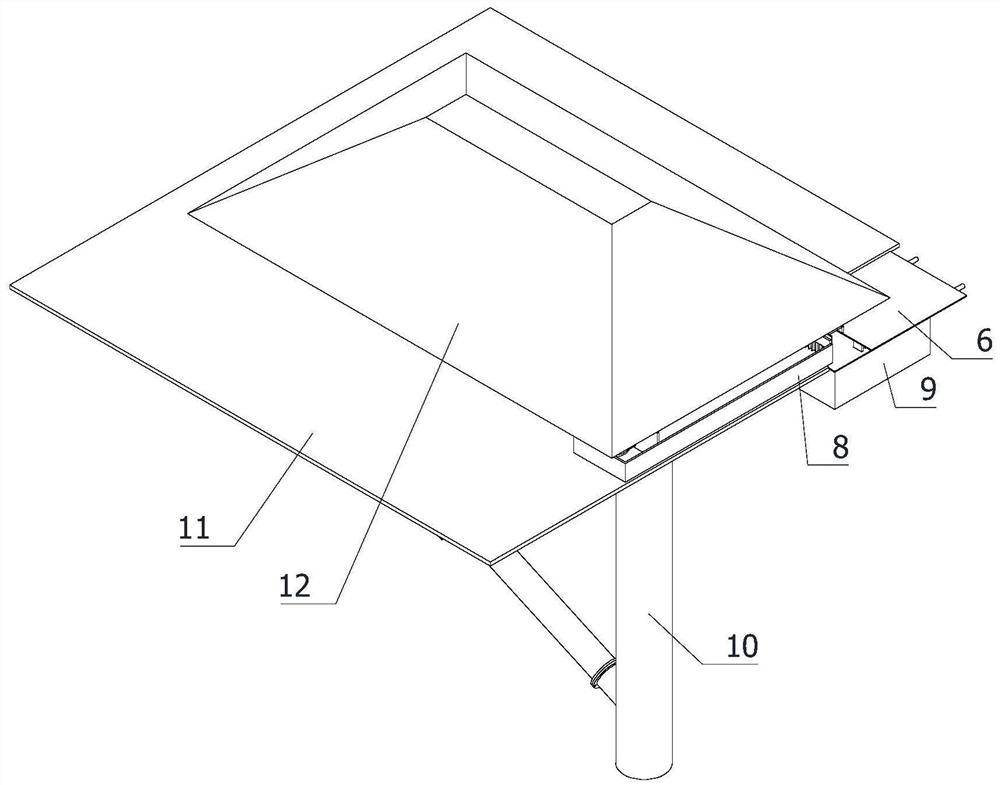

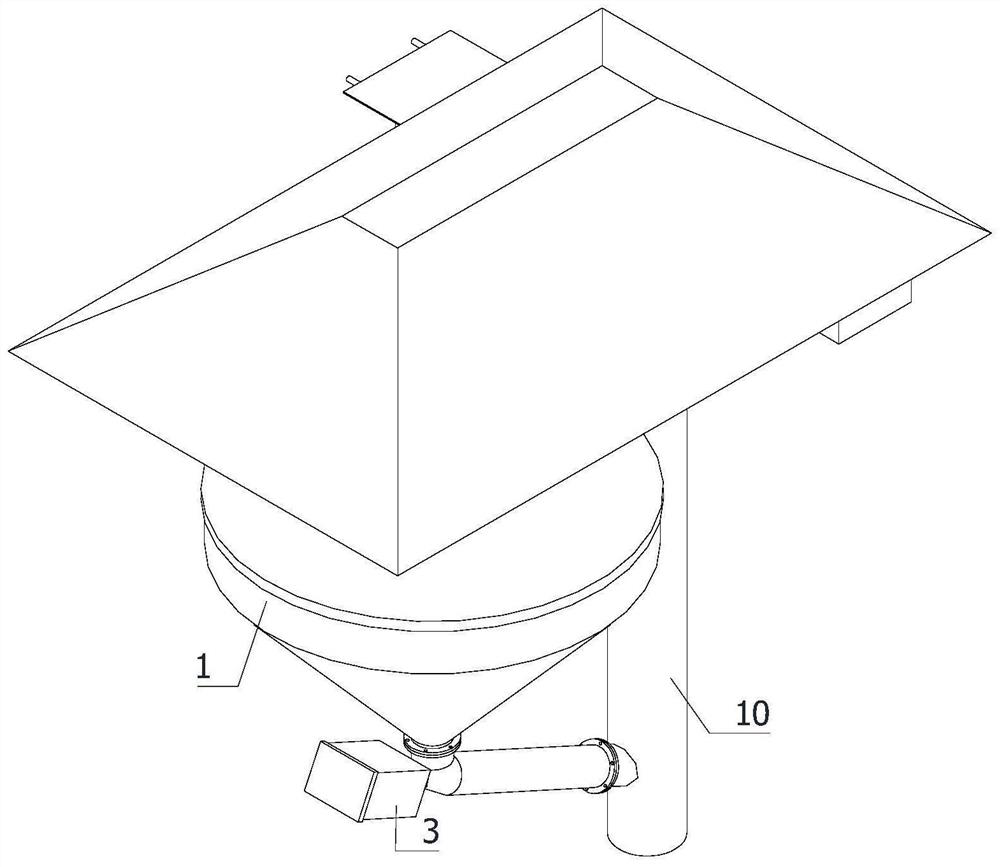

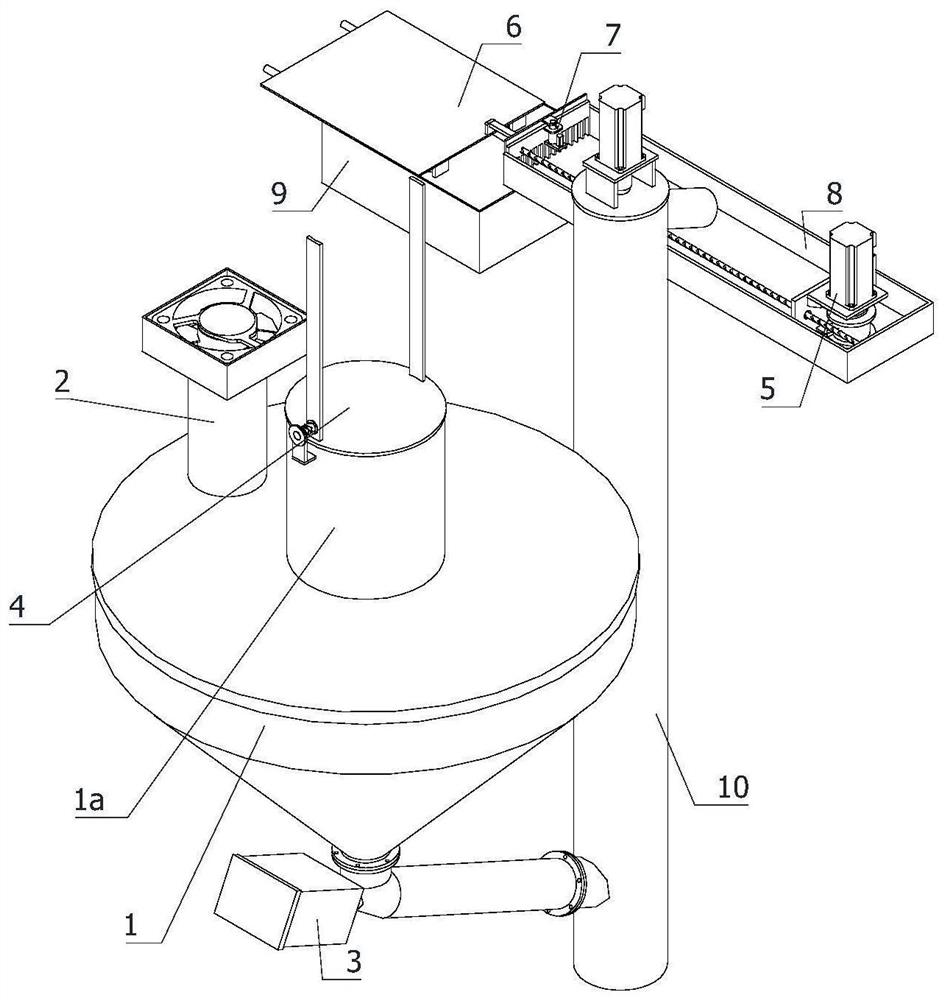

[0043] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0044] Wherein, the accompanying drawings are only for illustrative purposes, showing only schematic diagrams, rather than physical drawings, and should not be construed as limitations on this patent; in order to better illustrate the embodiments of the present invention, some parts of the accompanying drawings will be omitted, Enlarged or reduced, does not represent actual product size.

[0045] refer to Figure 1 to Figure 16 The shown automatic feeding equipment for poultry includes a cooling storage mechanism, a screw elevator 10 and a feed box 8. The cooling storage mechanism is fixedly installed under the ground surface 11, and the outlet of the cooling storage mechanism is connected to the feed of the screw elevator 10. The feed box 8 is fixedly installed on the ground surface 11, the discha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com