Hysteresis comparison circuit for automatic gain adjustment of gas ultrasonic flowmeter and implementation method

A technology of automatic gain adjustment and hysteresis comparison circuit, which is applied in the direction of liquid/fluid solid measurement, measurement flow/mass flow, multiple input and output pulse circuits, etc., can solve the problems of frequent adjustment and improve the accuracy of measurement , solve the effect of frequent adjustment and reduce power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

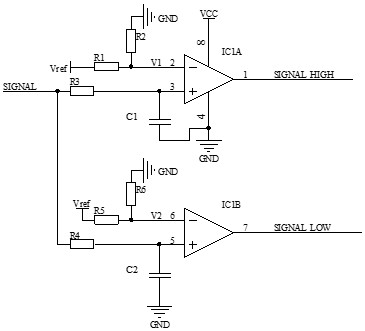

[0017] Below in conjunction with accompanying drawing, the present invention will be further described: as figure 1 as shown,

[0018] A hysteresis comparison circuit for automatic gain adjustment of a gas ultrasonic flowmeter, including a high threshold detection circuit and a low threshold detection circuit, wherein the inverting input terminal 2 of the comparator chip IC1A is connected to the high threshold comparison voltage V1, and V1 is controlled by the reference voltage Vref It is obtained by dividing the voltage between resistor R1 and resistor R2, and the other end of resistor R2 is grounded to GND;

[0019] The non-inverting input terminal 3 of the comparator chip IC1A is connected to the echo signal SIGNAL through the resistor R3, the capacitor C1 is a bypass capacitor, one end is connected to the non-inverting input terminal 3 of the comparator chip IC1A, and the other end is grounded to GND;

[0020] The inverting input terminal 6 of the comparator chip IC1B is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com