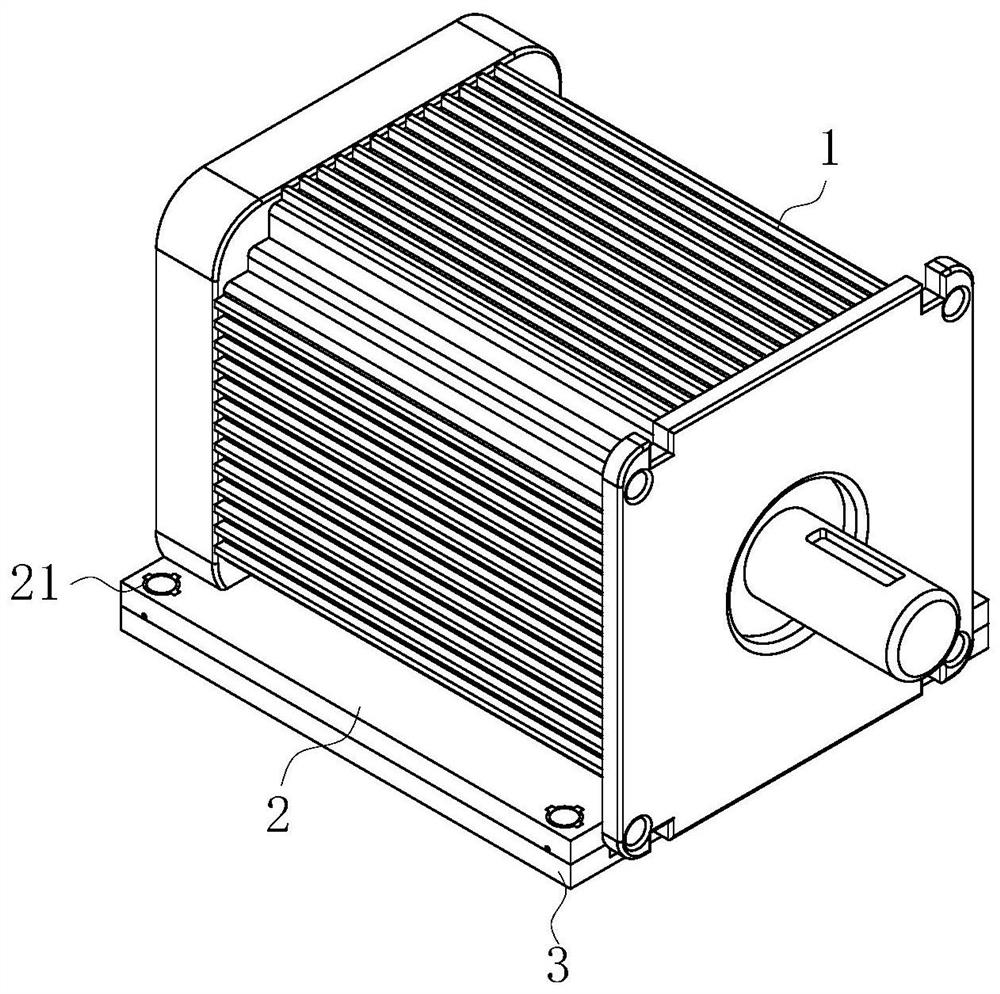

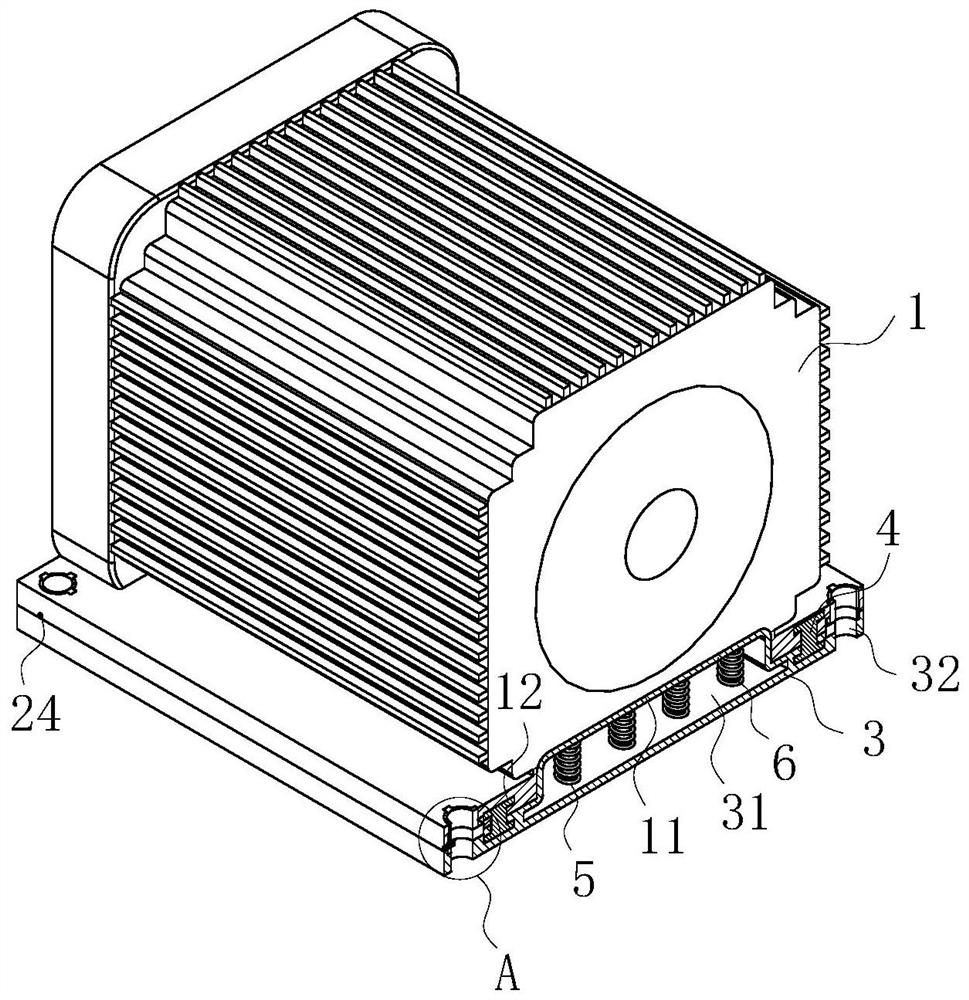

Permanent magnet brushless direct current motor

A permanent magnet brushless DC and permanent magnet technology, which is applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve problems that affect the service life of brushless DC motors, difficult motor maintenance and replacement, etc., so as to facilitate quick disassembly and maintenance operations, Improved cushioning and shock absorption effect, high impact absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

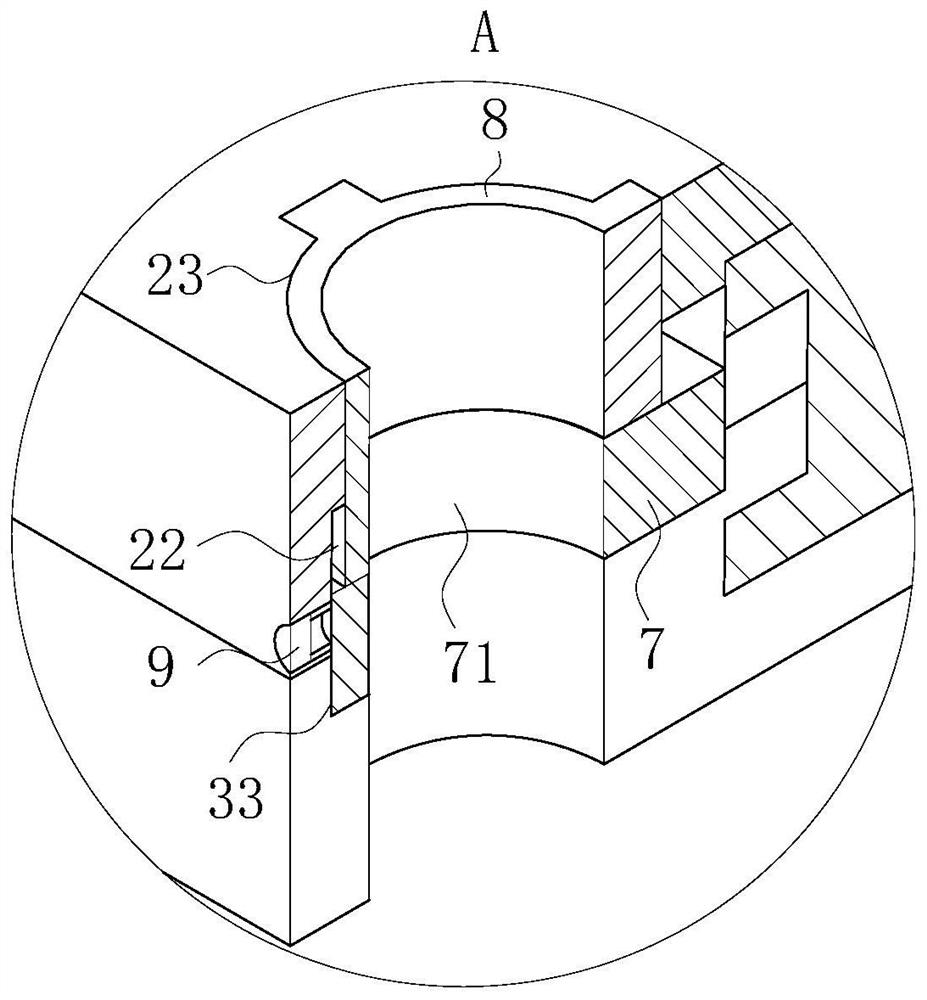

[0024] As an embodiment of the present invention, the lower end surface of the mounting plate 2 is provided with a plurality of limiting cavities 22, and the limiting blocks 7 are slidingly arranged in the plurality of limiting cavities 22; the plurality of limiting cavities 22 The depth is greater than the thickness of the limit block 7; the upper end surface of the limit block 7 is connected to the limit cavity 22 through the limit spring; the upper end surface of the two side walls of the fixed base 3 is provided with a plurality of insertion cavities 33, And a plurality of insertion cavities 33 are respectively aligned with a plurality of limiting cavities 22; a plurality of said insertion cavities 33 are slidably inserted into the limiting block 7, and the thickness of the limiting block 7 is greater than the depth of the insertion cavity 33; when working, when When the machine housing 1 is slidably installed on the upper end surface of the fixed base 3, it is necessary to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com