Thermal power generating unit coal conveying belt intelligent inspection device and method

A technology for intelligent inspection and thermal power generation, applied in TV, color TV, electrical components, etc., can solve problems such as low work efficiency and accuracy, ensure safe and stable operation, prevent fault expansion, and achieve all-round coverage without dead ends Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

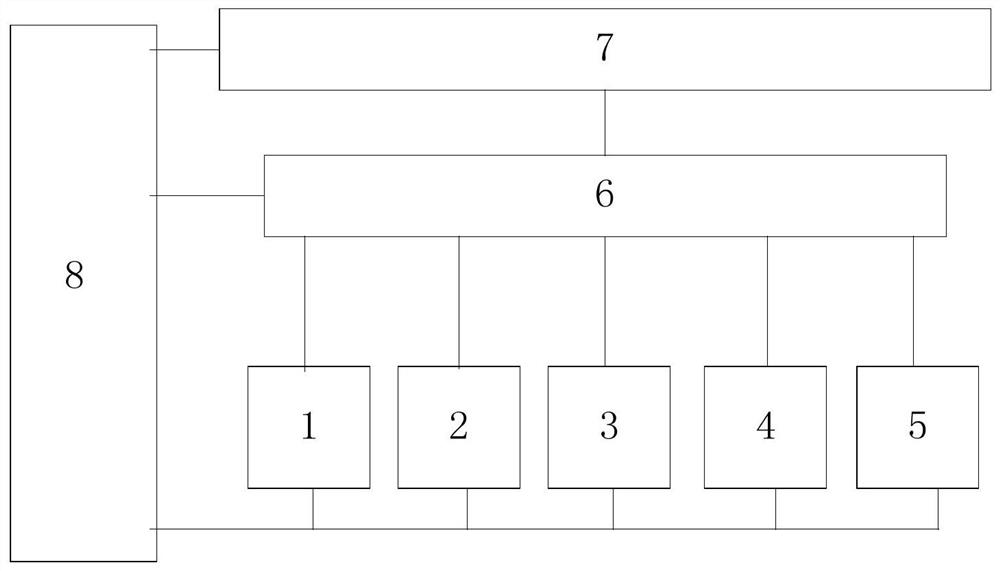

[0090] as attached figure 1As shown, both the dual-spectrum camera and the infrared thermal imaging camera are installed in a pan-tilt manner, with a horizontal rotation angle of 0° to 360° and a vertical rotation angle of 90°, which is convenient for field of view adjustment. The dual-spectrum camera is waterproof and dustproof For the shell, you can choose a high-definition dual-light camera model DS-2CD3T25D; the infrared thermal imager requires specifications as follows, the image resolution is 384 horizontal pixels, 288 vertical pixels, the wavelength is 8 to 14 microns, and the number of temperature measurement points is 110592 , you can choose a thermal imager model of Fotric 626; the dust concentration sensor with RS485 interface can be used for the pulverized coal concentration detector; the pickup and speaker can use industrial active sound sensors and loudspeakers, and the power supply voltage is 24V; the core controller 6 The processor can choose Zynq7010; the driv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com