Method for in-situ real-time quantitative diagnosis of fusion device surface wall part corrosion deposition

A real-time quantitative and in-situ technology, applied in the field of plasma measurement, can solve the problems of poor quantitative analysis accuracy, failure to meet the requirements of fusion device for wall diagnosis, difficulty in determining whether corrosion occurs and the depth of corrosion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

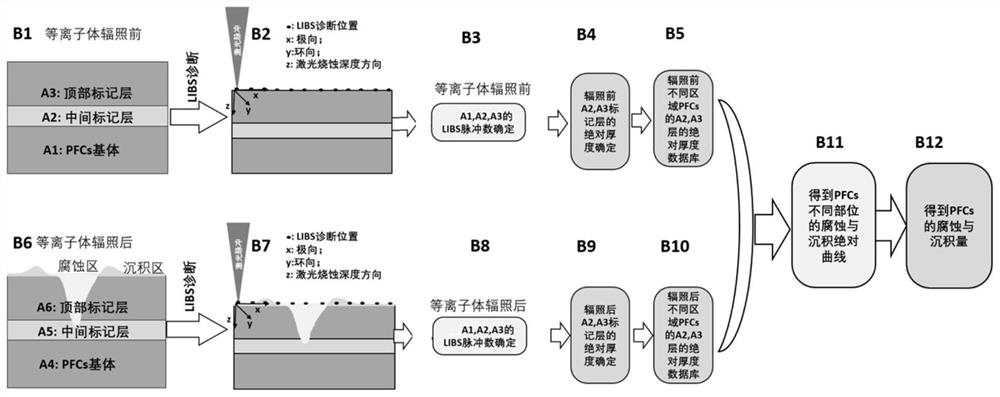

[0058] The present invention will be further described below by means of the accompanying drawings and specific embodiments.

[0059] The method is described in the following steps.

[0060] B1) Fixed placement of multilayer PFCs before plasma irradiation.

[0061] The multilayer PFCs include PFCs substrate A1 at the bottom, middle marking layer A2, and top marking layer A3. The specific positional relationship of A1, A2, and A3 is that A1 is located at the bottom, A2 is located above A1, A3 is located above A2, and the three layers are closely connected.

[0062] The material of the substrate A1 is the same as that of the main body wall of the fusion device, the material of the middle marking layer A2 must be different from A1 and A3, and the material of the top marking layer A3 can be any other material except the middle marking layer A2, which can be determined according to the research task, such as research For the etching and deposition of the tungsten wall, the top ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com