A quasi-zero-stiffness vertical vibration isolator capable of adjusting the equilibrium position

A technology of quasi-zero stiffness and balanced position, applied in the functional characteristics of spring/shock absorber, design characteristics of spring/shock absorber, vibration suppression adjustment, etc., can solve the problem of reducing system stiffness, reducing system bearing capacity, and large static displacement etc. to achieve the effect of reducing the natural frequency, improving low-frequency vibration isolation performance, and isolating low-frequency vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

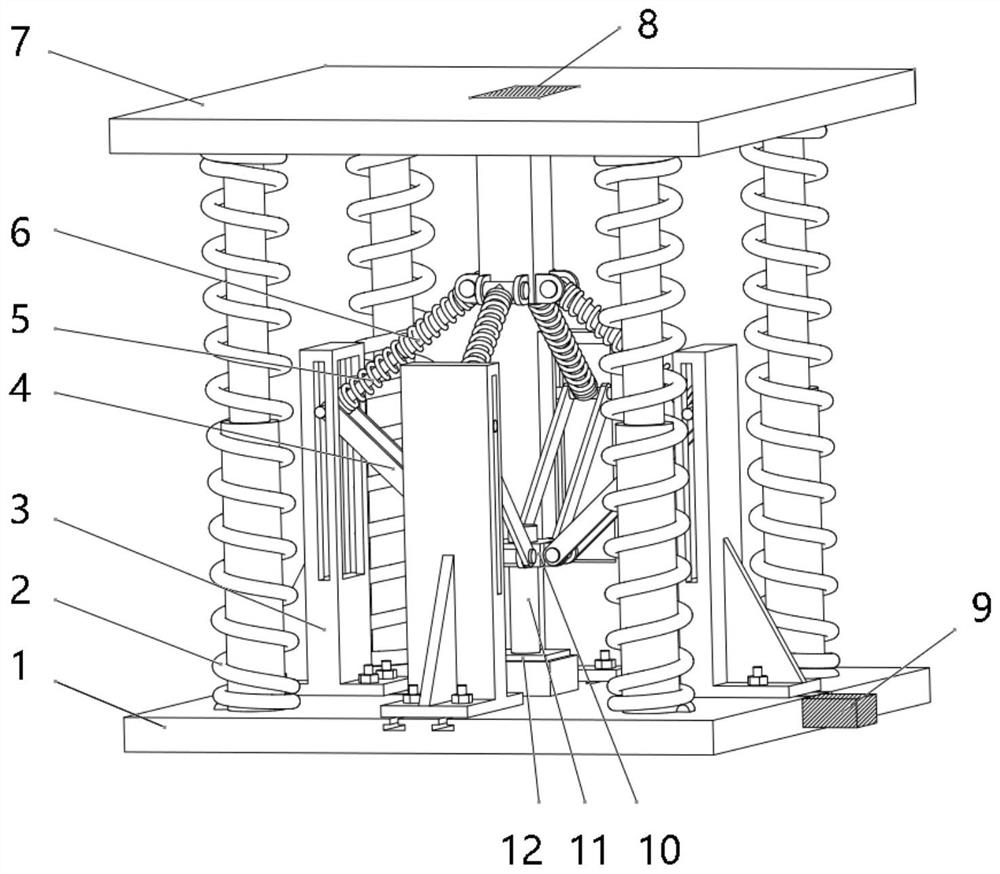

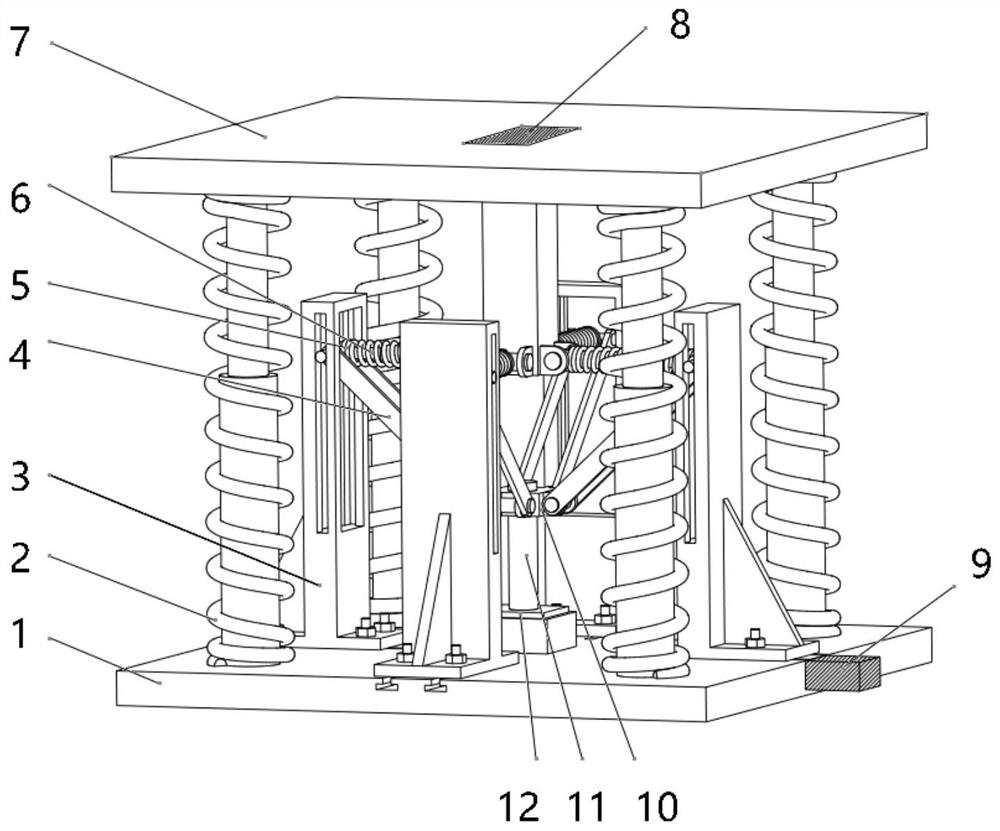

[0034] Such as figure 1 , 2 As shown, the present invention provides a quasi-zero-stiffness vertical vibration isolator capable of adjusting the equilibrium position, including a bearing platform 7, a support module, a positive stiffness mechanism, a negative stiffness mechanism, a transmission module and a control module.

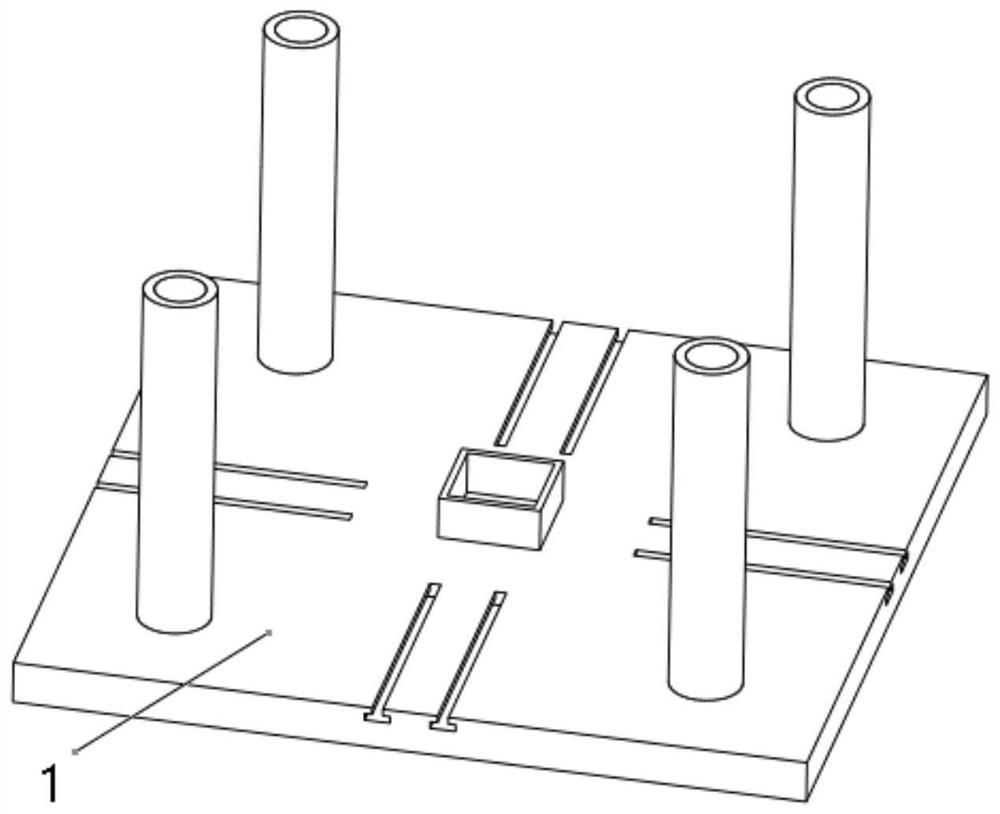

[0035] Four cylinders are arranged symmetrically at the bottom of the bearing platform 7, such as image 3 As shown, the upper end of the base 1 is provided with four cylindrical holes for the insertion of the cylinder, and the cylinder and the cylindrical holes are slidably connected.

[0036] The positive stiffness mechanism is composed of four positive stiffness springs 2, which are sleeved on the cylindrical hole and the outside of the cylinder,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com