Micro suspension panel mounting structure achieving strong vibration feedback

A technology of vibration feedback and installation structure, applied in the field of automotive interior parts, can solve the problems of panel impact abnormal noise, friction impact abnormal noise, etc., and achieve the effect of eliminating abnormal noise and increasing authenticity and experience.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

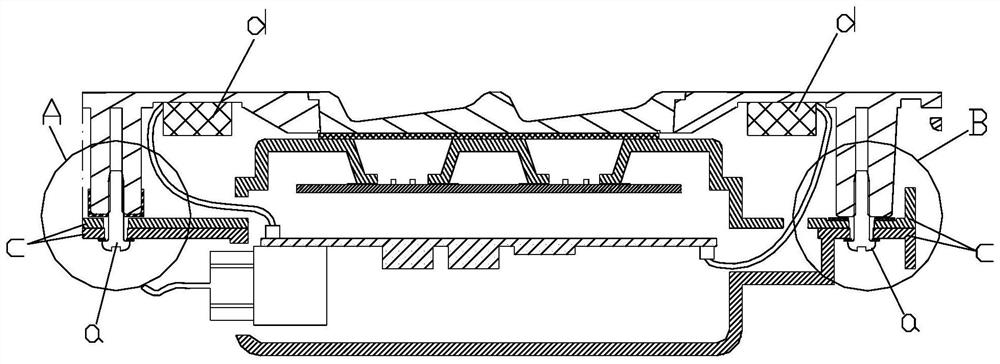

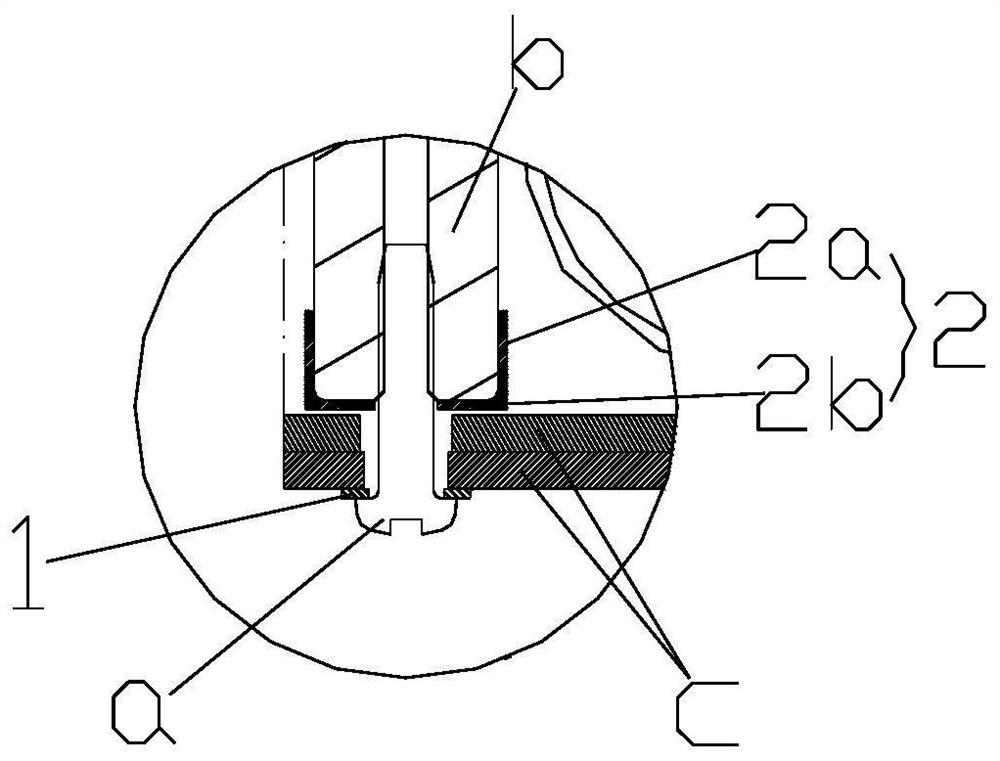

[0039] see figure 1 and figure 2 , this embodiment provides a micro-suspension panel installation structure with strong vibration feedback, including an elastic energy-absorbing screw pad 1 that can be sleeved on the screw a, the elastic energy-absorbing screw pad 1 is a washer structure, and the elastic energy-absorbing screw pad 1 is a washer structure. The diameter of the inner ring of the screw pad 1 matches the outer diameter of the screw part of the screw a, and the diameter of the outer ring of the elastic energy-absorbing screw pad 1 matches the outer diameter of the screw head part of the screw a. By adding an elastic energy-absorbing screw pad 1 between the screw a and the counterpart c, since the elastic energy-absorbing screw pad 1 is made of an elastic energy-absorbing material, when the panel vibrates, on the one hand, the elastic energy-absorbing screw pad 1 The relative position between the panel and the counterpart can be moved (the amount of movement is ver...

Embodiment 2

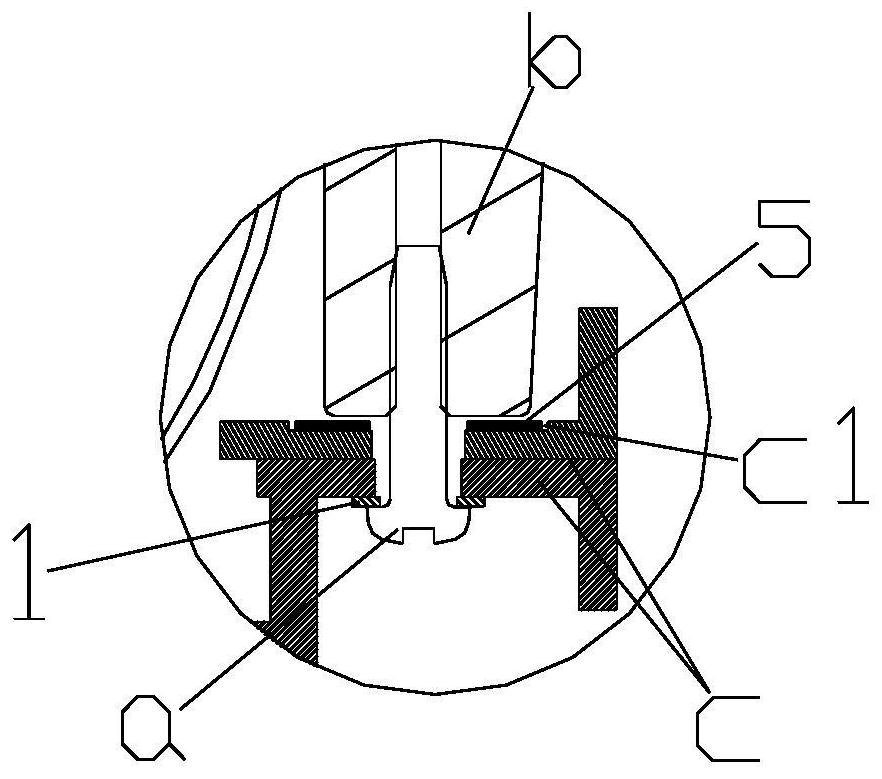

[0042] see figure 1 and image 3 , this embodiment provides a micro-suspension panel installation structure with strong vibration feedback, including an elastic energy-absorbing screw pad 1 that can be sleeved on the screw a, the elastic energy-absorbing screw pad 1 is a washer structure, and the elastic energy-absorbing screw pad 1 is a washer structure. The diameter of the inner ring of the screw pad 1 matches the outer diameter of the screw part of the screw a, and the diameter of the outer ring of the elastic energy-absorbing screw pad 1 matches the outer diameter of the screw head part of the screw a. By adding an elastic energy-absorbing screw pad 1 between the screw a and the counterpart c, since the elastic energy-absorbing screw pad 1 is made of an elastic energy-absorbing material, when the panel vibrates, on the one hand, the elastic energy-absorbing screw pad 1 The relative position between the panel and the counterpart can be moved (the amount of movement is very...

Embodiment 3

[0045] see Figure 4 and Figure 5 , this embodiment provides a micro-suspension panel installation structure with strong vibration feedback, including an elastic energy-absorbing screw pad 1 that can be sleeved on the screw a, the elastic energy-absorbing screw pad 1 is a washer structure, and the elastic energy-absorbing screw pad 1 is a washer structure. The diameter of the inner ring of the screw pad 1 matches the outer diameter of the screw part of the screw a, and the diameter of the outer ring of the elastic energy-absorbing screw pad 1 matches the outer diameter of the screw head part of the screw a. By adding an elastic energy-absorbing screw pad 1 between the screw a and the counterpart c, since the elastic energy-absorbing screw pad 1 is made of an elastic energy-absorbing material, when the panel vibrates, on the one hand, the elastic energy-absorbing screw pad 1 The relative position between the panel and the counterpart can be moved (the amount of movement is ve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com