Expansive soil texture improved roadbed structure in seasonally frozen soil area

A soil improvement and expansive soil technology, applied in the direction of roads, roads, climate sustainability, etc., can solve the problems that threaten the quality and safety of the project, the soil moisture is difficult to discharge, and the strength is reduced, so as to improve the strength and freeze-thaw resistance, The effect of reducing land occupation and environmental pollution, high hardness and durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

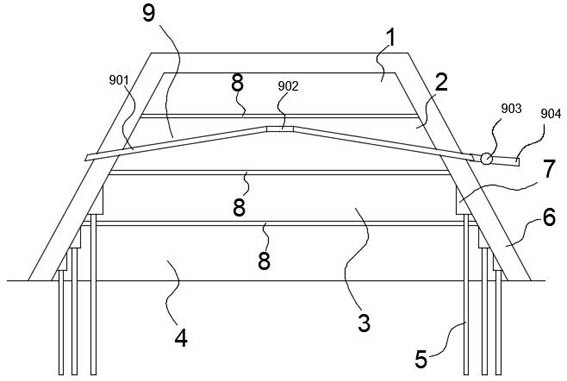

[0033] like figure 1 As shown, a subgrade structure of expansive soil improvement in seasonal frozen soil areas, the improved subgrade structure is a multi-layer composite structure, and the outside of the multi-layer composite structure is covered with a subgrade wrapping soil layer 6, and the multi-layer composite structure The structure from top to bottom is the first improved reinforcement layer 1, the construction waste filling layer 2, the second improvement reinforcement layer 3 and the construction waste filter layer 4, the first improvement reinforcement layer 1 and the second improvement reinforcement layer 3 The ingredients are the same, and the preparation method is: first mix the steel slag powder and expansive soil with a mass ratio of 1:4 to form a preliminary improved expansive soil mixture, then crush the construction waste to a particle size of no more than 10mm, and then mix it with the preliminary improved expansive soil The soil mixture is mixed at a mass ...

Embodiment 2

[0038] This embodiment is an improvement made on the basis of embodiment 1, its main structure is the same as that of embodiment 1, and the improvements are as follows: figure 1 As shown, the cross-section of the improved roadbed structure is an isosceles trapezoid with a narrow top and a wide bottom, and L-shaped card platforms 7 extending along the roadbed are arranged on both sides of the construction waste filter layer 4 and the second improved reinforcement layer 3 , and these L-shaped card platforms 7 cooperate with the roadbed edge-wrapping soil layer 6 on the side to form a cavity with a right-angled triangle section, and fill the cavity with collapsible loess;

[0039] On the bottom wall of each cavity, several deep holes are drilled vertically downwards along the extension direction of the subgrade, until they penetrate 0.8-1.5m into the expansive soil surface below the construction waste filter layer 4, and then drill into each deep hole. Inject cement mortar, and f...

Embodiment 3

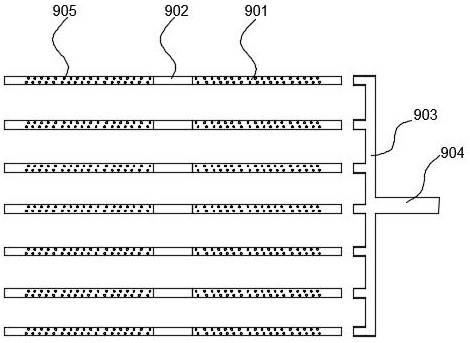

[0041] This embodiment is an improvement made on the basis of embodiment 2, its main structure is the same as that of embodiment 2, and the improvements are as follows: figure 1 and 2 As shown, there are several ventilation and drainage mechanisms 9 distributed in the construction waste filling layer 2 along the extension direction of the roadbed, and each group of ventilation and drainage mechanisms 9 includes several groups of ventilation and drainage mechanisms buried in the construction waste filling layer 2 along the extension direction of the roadbed. Pipe assembly, each group of ventilation pipe assembly includes two inclined pipes 901 and a ventilation main pipe 903 located outside the improved roadbed structure and in the same direction as the roadbed extension, the two inclined pipes 901 are distributed on both sides of the construction waste filling layer 2 , and the adjacent one end is connected as a whole through the pipe joint 902, and the free ends of the two in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com