Cutting device for enhanced polyethylene winding pipe

A cutting device, polyethylene technology, applied in metal processing, instruments, sounding equipment, etc., can solve the problems of winding pipes not being firmly fixed, staff injury, flying debris pollution, etc., to facilitate cleaning, reduce labor intensity, and prevent noise pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

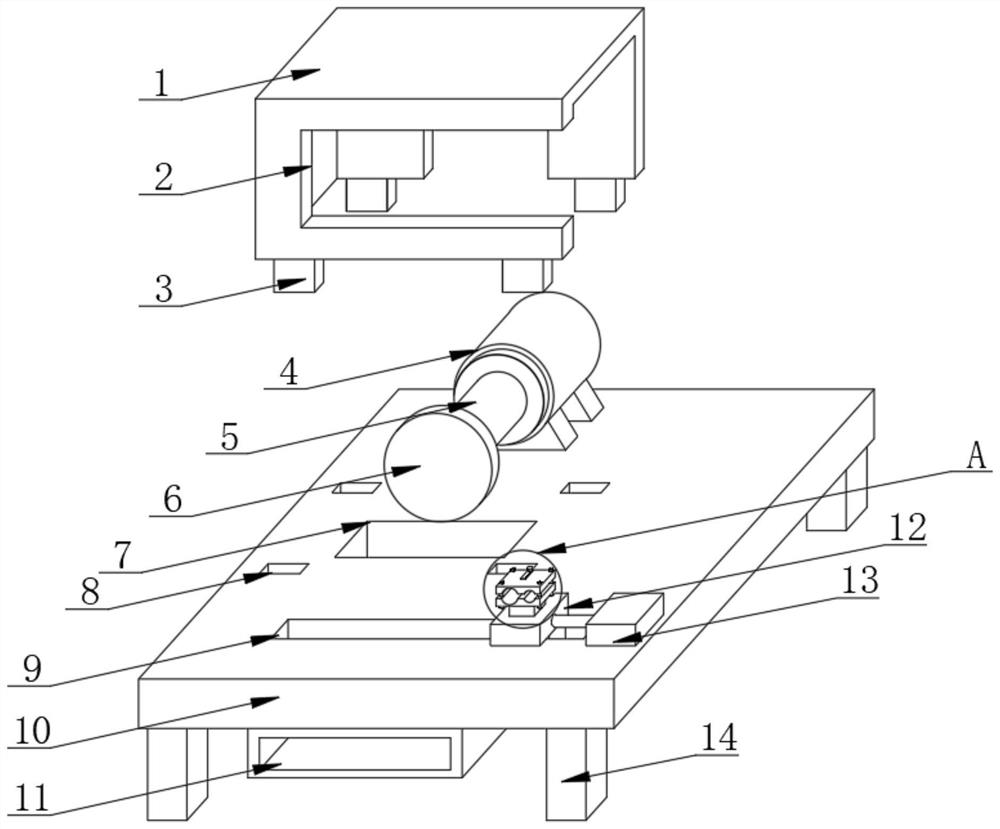

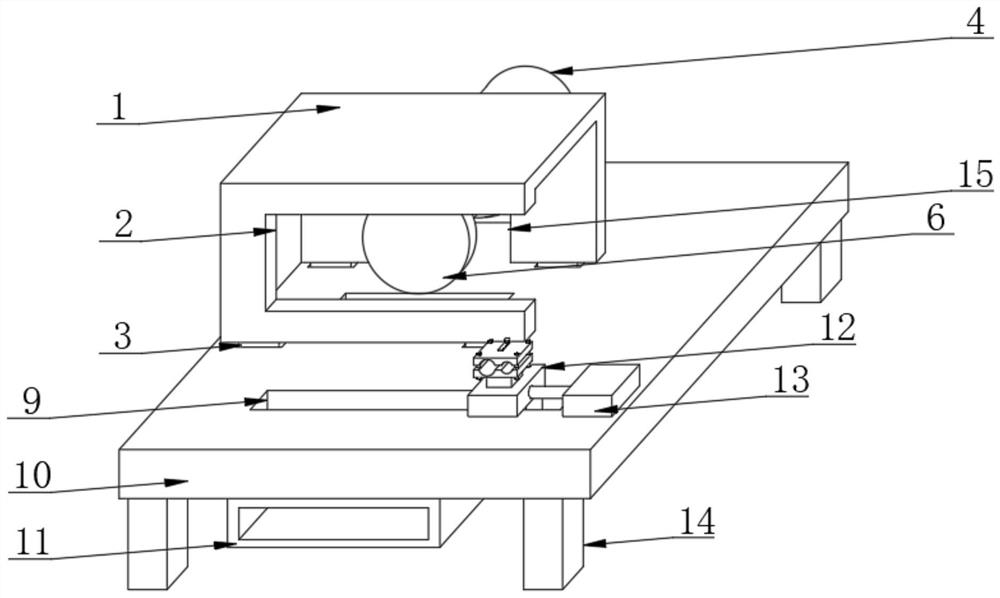

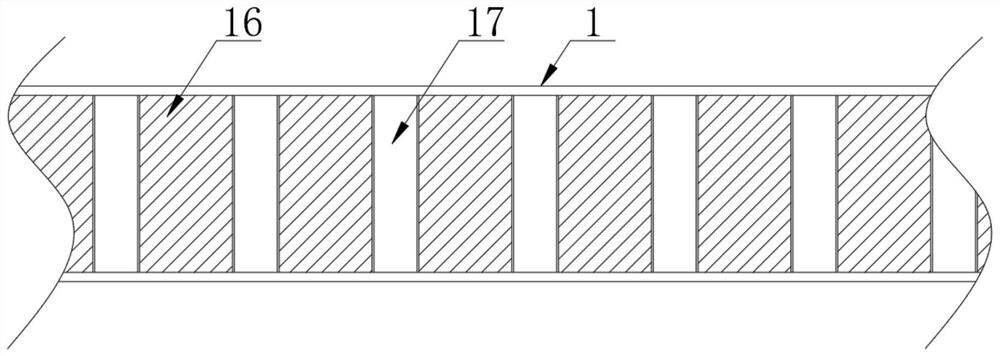

[0025] see Figure 1~5 , in the embodiment of the present invention, a kind of reinforced polyethylene winding pipe cutting device comprises workbench 10, and the bottom of workbench 10 is welded with base 14, and the upper surface of workbench 10 is fixedly installed with cutting motor 4, and cutting motor 4 A rotating shaft 5 is connected to the driving end of the rotating shaft 5, a cutting piece 6 is fixedly connected to the front surface of the rotating shaft 5, a drop hole 7 is opened on the upper surface of the workbench 10 just below the cutting piece 6, and a Recovery box 11, the upper surface of workbench 10 is slidingly installed with mobile plate 12 in the place ahead of drop hole 7, and the upper surface of workbench 10 is provided with electric telescopic link 13, and the telescopic end of electric telescopic link 13 is connected with mobile plate 12, A connecting rod 28 is installed at the middle position of the lower surface of the moving plate 12, and the bott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com