A express automatic sorting equipment

An automatic sorting and equipment technology, applied in the direction of sorting, cleaning methods using gas flow, cleaning methods and utensils, can solve the problems of express delivery damage, high labor intensity, loss, etc., to achieve good practicability and prevent loss , reduce the effect of damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

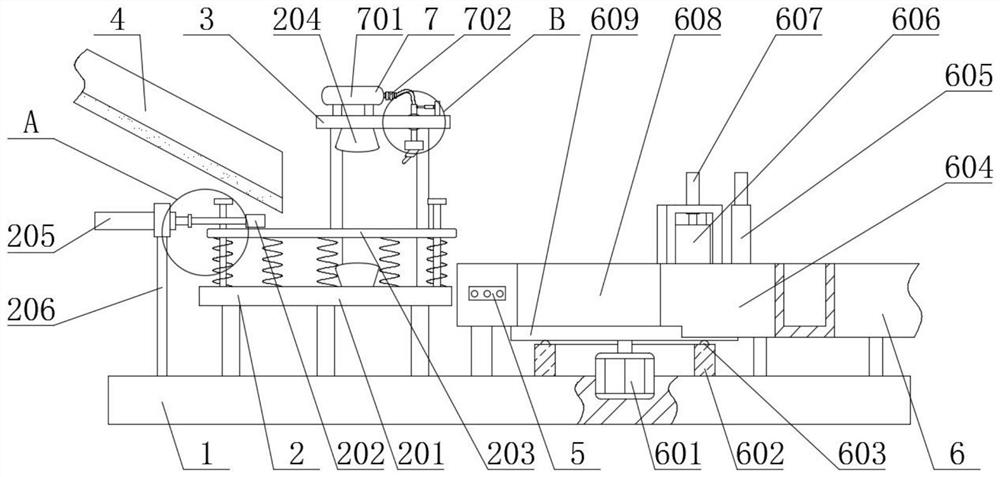

[0026] see Figure 1-5 , the present invention provides a technical solution:

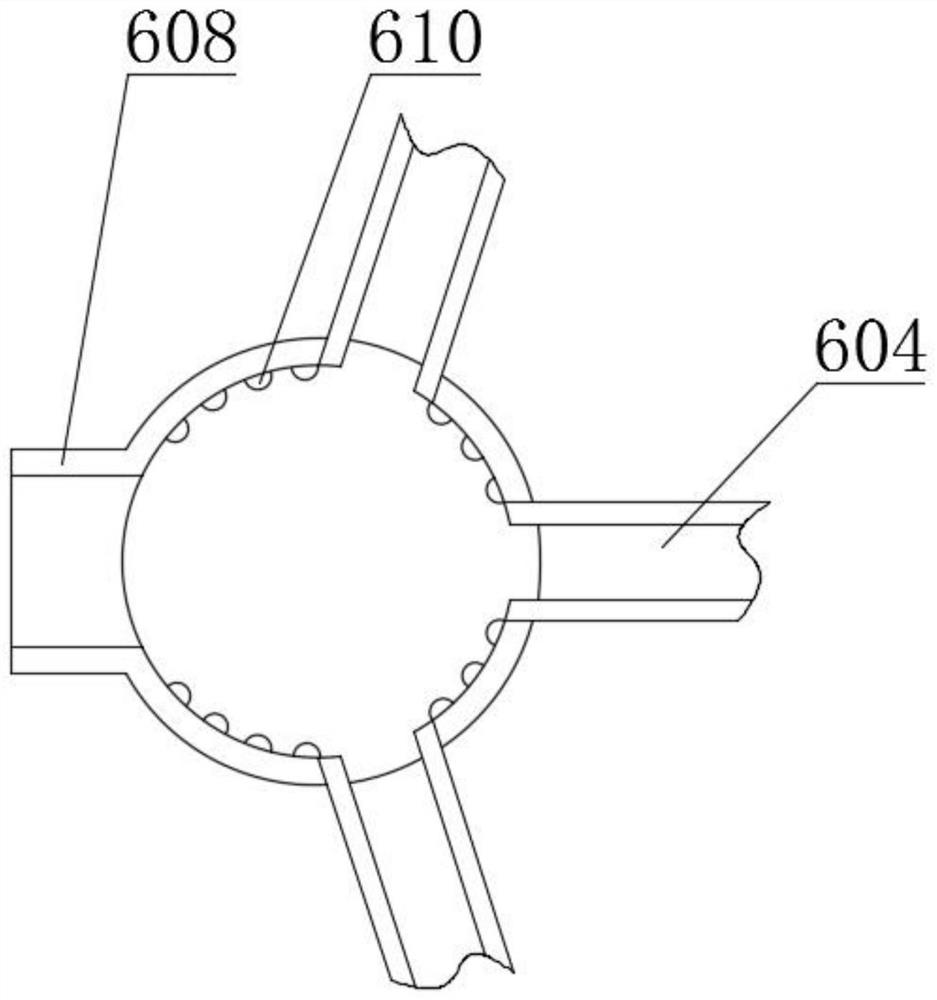

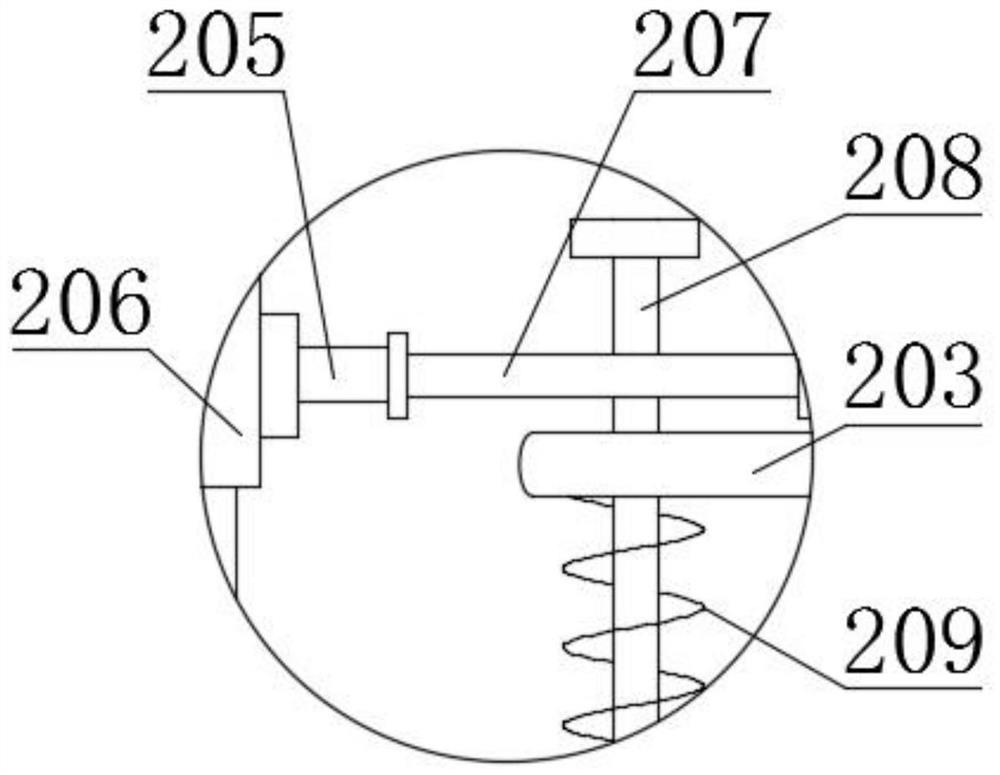

[0027] An express automatic sorting device, comprising a base 1, a feeding slope 4 and a controller 5, a blanking identification device 2 is arranged on the upper left end of the base 1, and a support plate 3 is fixedly connected to the top of the base 1, as shown in the support plate 3 is provided with a blanking plate cleaning device 7, and the upper right side of the base 1 is provided with a sorting device 6, which can push the courier into the inner side of the required discharge plate 604, and the sorting device 6 includes a sorting device Picking tray 608, discharge plate 604, top ring 602 and motor 601, the end of the main shaft of motor 601 is fixedly connected with turntable 609, the top of turntable 609 is slidingly connected with the bottom end of sorting tray 608, the top left side of discharge plate 604 Fixedly connected with a fixed frame 605, the top inside of the fixed frame 605 i...

Embodiment 2

[0031] Workflow: In embodiment 2, the same parts as in embodiment 1 will not be repeated. The difference is that, because the express delivery will inevitably be contaminated with some dust during the transportation process, the express delivery will drop to the upper side of the blanking plate 203. At the same time, these dusts may fall on the blanking plate 203. After a certain period of time, the dust contaminated on the blanking plate 203 will directly affect the recognition of the recognition camera 204. The blanking plate 203 needs to be cleaned regularly. , the controller 5 will control the solenoid valve 702 to open. After the solenoid valve 702 is opened, the high-pressure air inside the compressed air bottle 701 will pass through the air pipe 703, the rotating ball 705, the connecting plate 706 in turn, and finally be ejected by the air nozzle 707. The high-pressure gas will Blow off the contaminated dust on the blanking plate 203, so as to clean the blanking plate 20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com