A timing feeding device for forage material for beef cattle breeding

A beef cattle breeding and forage technology, applied in the field of livestock breeding, can solve the problems of low degree of automation and inability to realize automatic feeding, and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

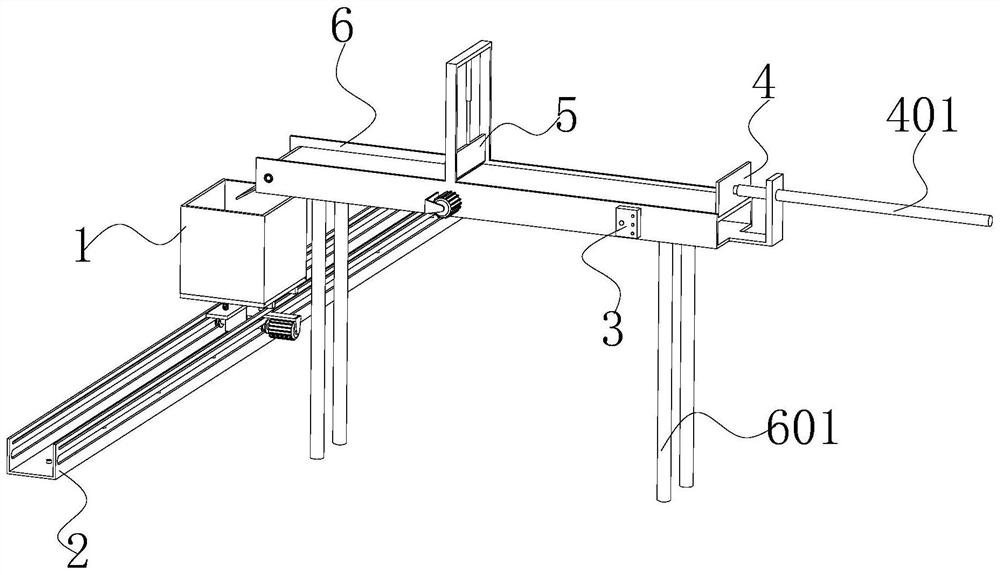

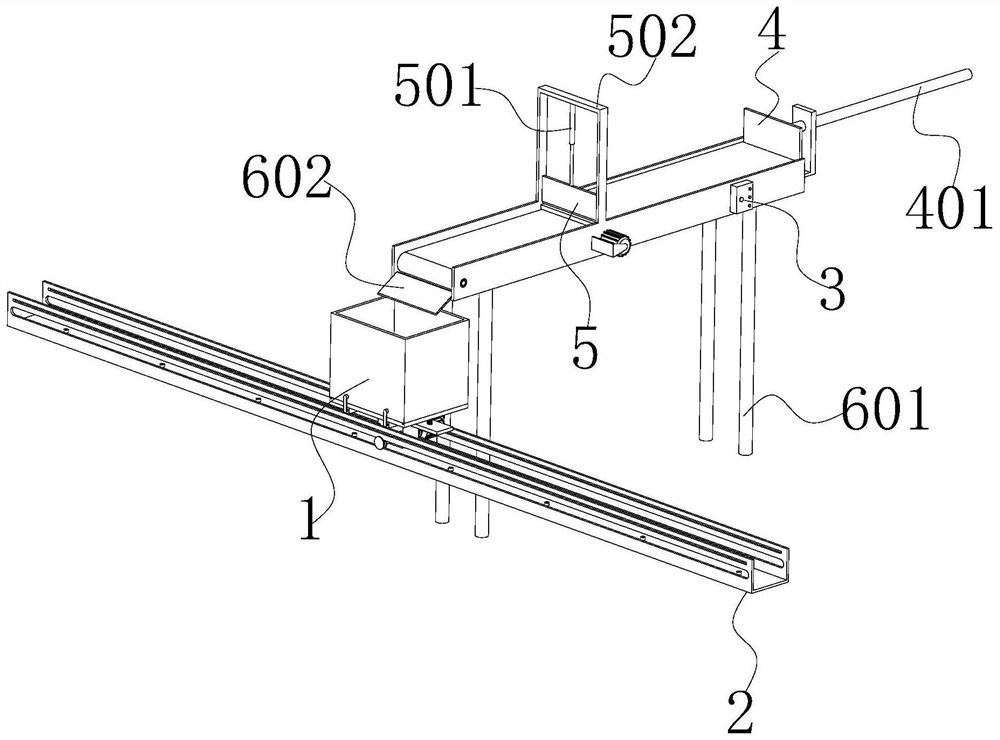

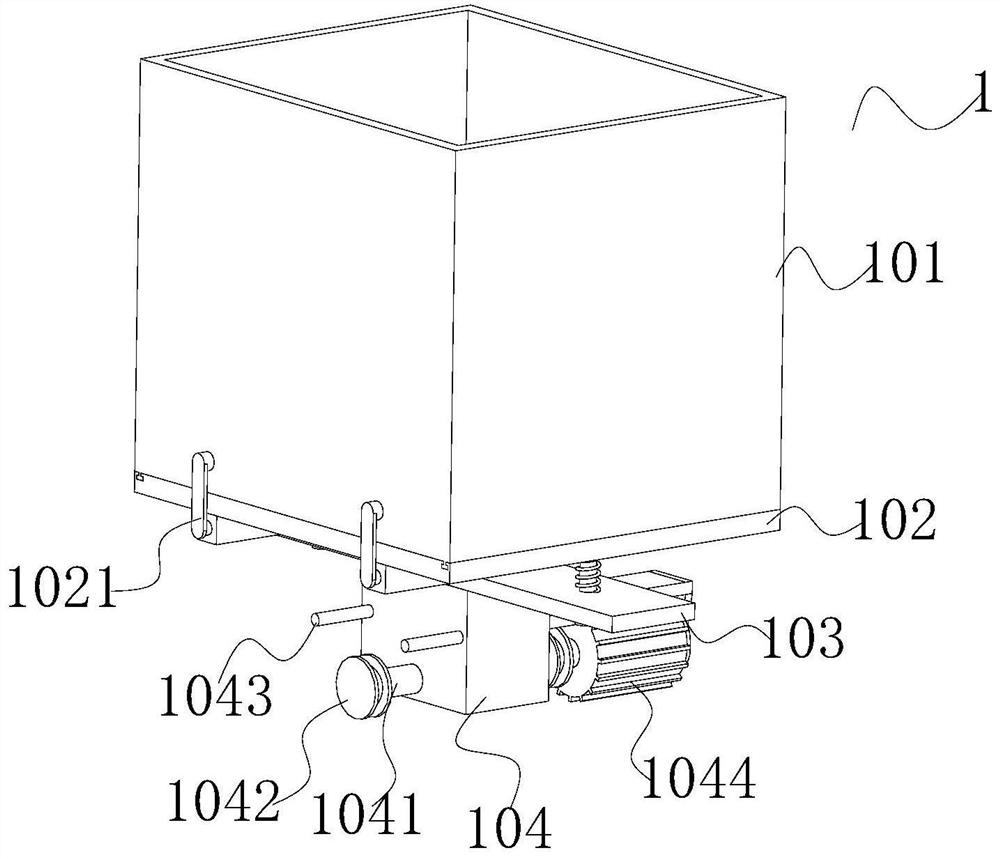

[0049] see Figure 1-2 As shown, the present invention is a timing feeding device for forage material for beef cattle breeding, comprising a feeding mechanism 1, a positioning platform 2 and a transport frame 6, as can be seen from the accompanying drawings, the above-mentioned components constitute the basic composition of the device, and the positioning A feeding mechanism 1 is arranged on the platform 2, and a conveying frame 6 is arranged on the upper side of the feeding mechanism 1, and the distance between the conveying frame 6 and the positioning platform 2 is arranged horizontally and vertically, and the setting of the conveying frame 6 is used for pretreatment of forage , the setting of the feeding mechanism 1 is used for automatic feeding of forage after pretreatment;

[0050] The four corners of the bottom surface of the conveying frame 6 are fixedly connected with supporting columns 601, and the setting of the supporting columns 601 is used for supporting and dampi...

Embodiment 2

[0071] see Figure 1-2As shown, the present invention is a timing feeding device for forage material for beef cattle breeding, comprising a feeding mechanism 1, a positioning platform 2 and a transport frame 6, as can be seen from the accompanying drawings, the above-mentioned components constitute the basic composition of the device, and the positioning A feeding mechanism 1 is arranged on the platform 2, and a conveying frame 6 is arranged on the upper side of the feeding mechanism 1, and the distance between the conveying frame 6 and the positioning platform 2 is arranged horizontally and vertically, and the setting of the conveying frame 6 is used for pretreatment of forage , the setting of the feeding mechanism 1 is used for automatic feeding of forage after pretreatment;

[0072] The four corners of the bottom surface of the conveying frame 6 are fixedly connected with supporting columns 601, and the setting of the supporting columns 601 is used for supporting and dampin...

Embodiment 3

[0094] Based on each electrical component described in embodiment one and embodiment two, by the time relay in the PLC controller 3 can realize the regular feeding of forage, a plurality of infrared emitters 203 are parallel settings, the staff according to each feed Beef cattle fed in the trough are in different growth stages, and the specific forage quantitative setting is carried out and stored in the PLC controller 3, and the feeding amount is assigned to the infrared transmitter 203 at the corresponding feed trough position at the same time.

[0095] After the feeding time in the time relay arrives, the PLC controller 3 can control the infrared ray emitter 203 work one by one, when a certain infrared emitter 203 works, the PLC controller 3 controls the first cylinder 501, the second cylinder 401 and the second The second motor 603 works, and under the stretching effect of the second cylinder 401, the forage on the placement plate 607 can be pushed to one end of the conveyo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com